The right technique, Ransburg – Ransburg Vector Solo AA90 79698 User Manual

Page 23

Vector Solo AA90 Applicators - Operation

Ransburg

19

AH-08-04.2

THE RIGHT TECHNIQUE

Following are some basic electrostatic spray tech-

niques. Depending on the spray target, it may be

necessary to adjust the technique.

Spray Width Determination

The size of the object being coated is the deter-

mining factor in adjusting the spray pattern. The

larger the object, the larger the required pattern

width. This is accomplished by fluid nozzle se-

lection. Air adjustment is used to remove "tails"

from the spray pattern and adjust the pattern size.

The degree of atomization is depen-

dent on the viscosity of the paint formula-

tion, the applied fluid pressure, and nozzle

selection.

Applicator to Target Distance

The distance between the applicator and the tar-

get influences the appearance of the final finish

of the object. If the applicator is held too close,

under 100mm (approximately 4-inches), runs and

sags with excessive "bounce-back" may occur. If

the applicator is held too far from the object, the

electrostatic attraction is decreased. Normally,

the best spacing between applicator and target is

in the 150mm to 300mm area (6-inch to 12-inch).

The object being coated is maintained

at ground potential. The applicator opera-

tor is also grounded, therefore, the operator

has as much attraction for the electrostatic

paint as the object. To prevent "wrap-back"

always keep the applicator nozzle closer to

the target than to the operator.

Overlap

For the best "hiding" and uniformity of film thick-

ness, the stroke overlap should be approximately

50%. There should be some overlap at edges

of the part to increase edge coverage. Overlap

requirements may vary widely with different paint

formulations and different compositions of objects

being coated.

Triggering

Applicator triggering (ON/OFF) depends largely

on the desired results (the amount of wrap-around

required, edge coating, etc.). If the front and back

of the object are being coated, proper applicator

technique can edge coat in some instances without

making a specific pass for that purpose. Trig-

gering the applicator before the target is directly

in front of the applicator may cause heavy edge

build-up on the leading edge of the target due to

the electrostatic attraction.

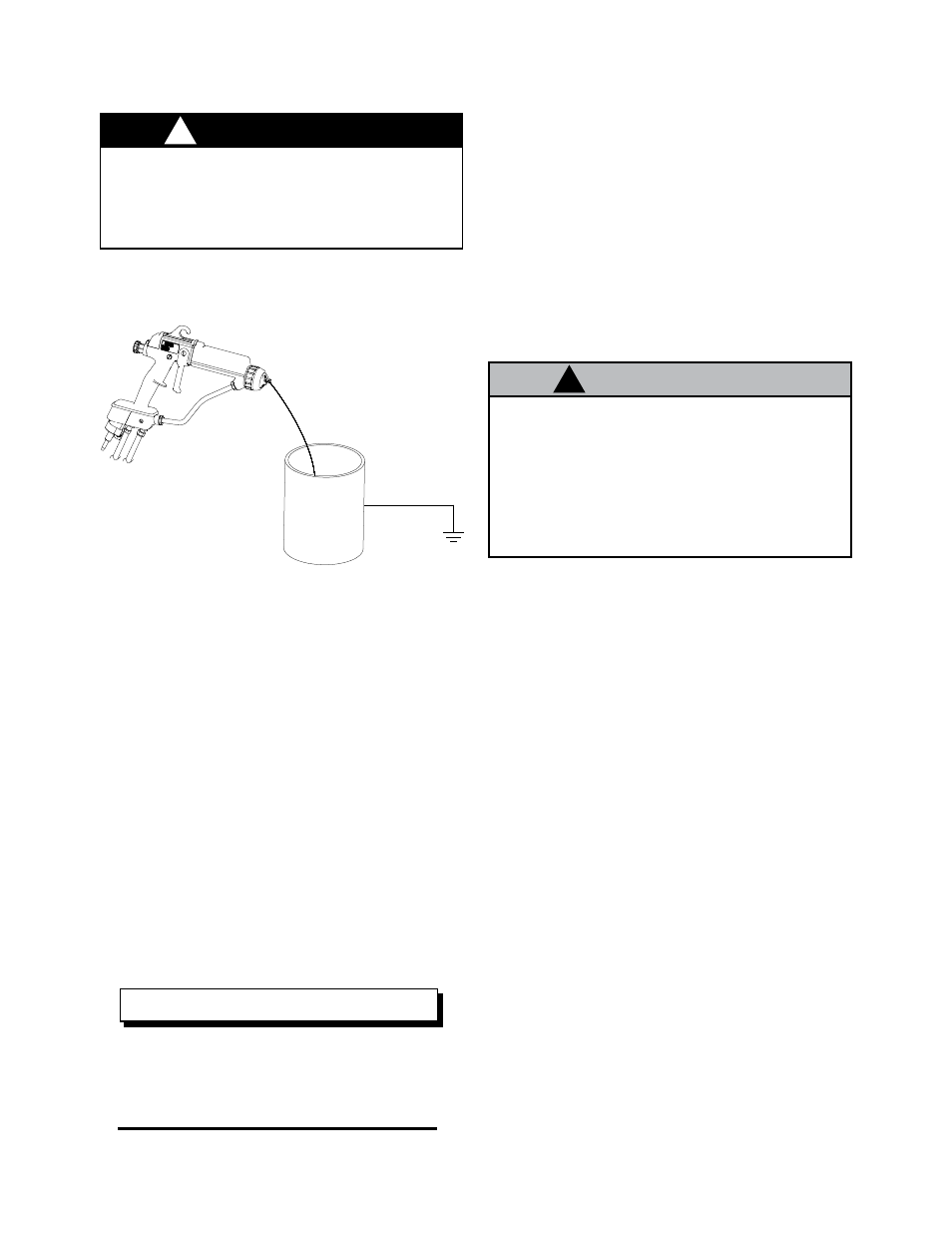

3. Relieve any fluid pressure, then discharge fluid

into appropriate grounded metallic container.

Figure 16: Applicator Flush Out

4. Load next color or remove applicator from

installation as required.

Supply air to the applicator must be in-

terlocked with the solvent supply. Supply air

must be off to the applicator when solvent

supply is on.

NOTE

C A U T I O N

!

W A R N I N G

!