Pump - driveline - hose installation, Figure 5, Figure 6 – Alamo Axtreme 02984405 User Manual

Page 52: Figure 3 figure 4

Axtreme Boom (Asy Man) 07/06

© 2006 Alamo Industrial

Section 6 - 4

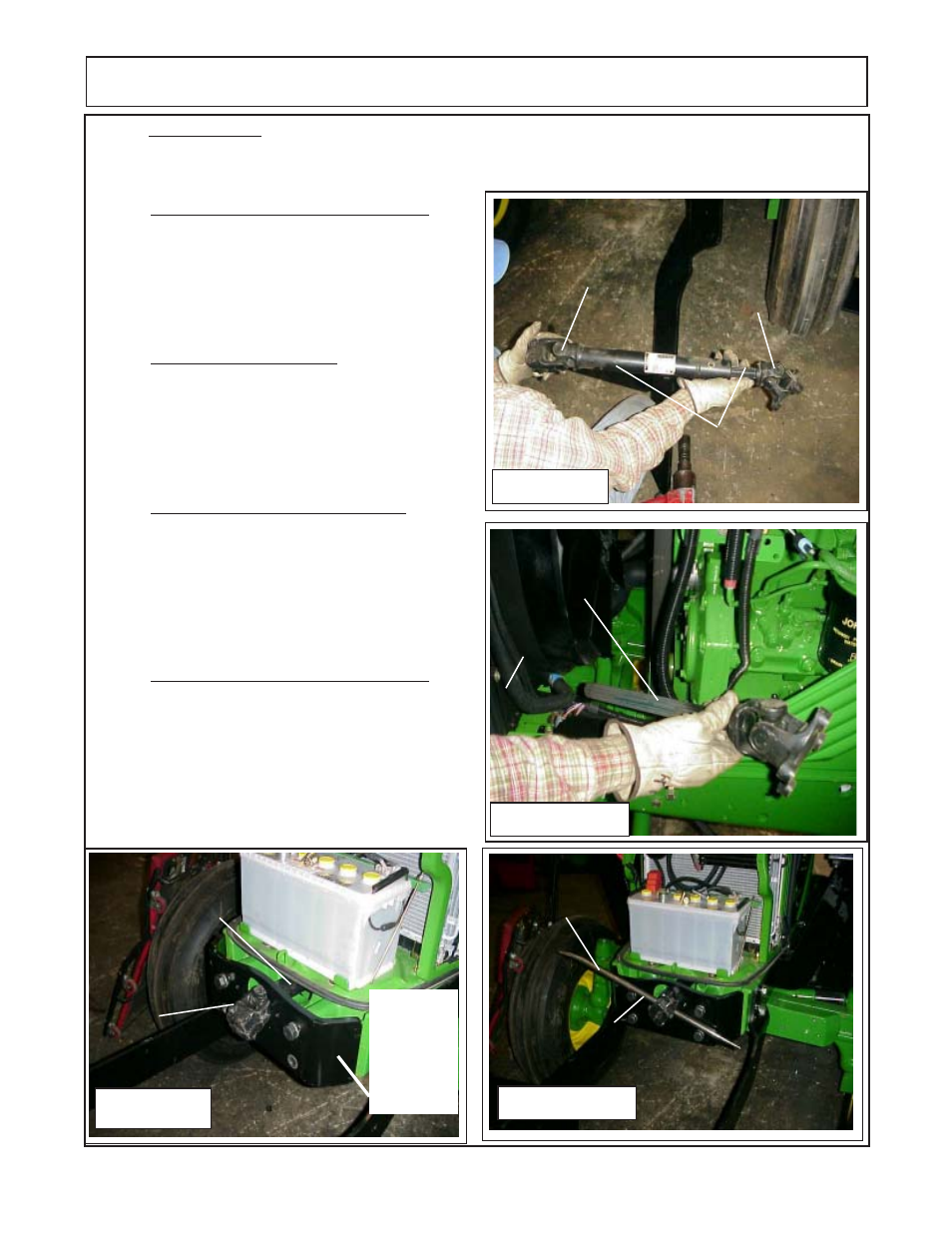

Figure 5

Tube End of

Driveshaft

Splined

Clamp Yoke

Typical

Pump

Mount

Plate

Shown

Figure 6

Bar to Hold

Drive Shaft

Driveshaft, Spline

Clamp Yoke End

4.

Driveline timeing means the universal joints are both the same position when driveline half is slid together. If

they are not timed, it will decrease the life of the universal joint and in some cases could cause a vibration. (See Figure

2 & 3), Driveline timing is critical to smooth operation.

Pump - Driveline - Hose Installation

Splined Clamp Yoke

/ Tube End

Flange Yoke

/ Shaft End

Drive Shaft

Assembly

Figure 3

Figure 4

Shaft 1/2 Assembly

w/ Flanged Yoke

Left Hand front side

of Tractor

Tractor Engine

Tractor

Radiator

5.

Install Tube End of Driveline / Pump End. Slide

the Tube half of driveshaft through Pump Mount Plate and

Tractor Crankshaft Access Hole (See Figure 8). You will

have to align the Universals when doing this (time the

Driveshaft). Slide the two together where the Universal are

in time (See Figure 2, 3 & 5) this will help the driveshaft

to operate smoothly.

6.

Loosen Splined Clamp Yoke. Insert a bar through

the Yoke to hold Driveshaft up and to help loosen the Bolts

in the clamp Yoke (See Figure 6). This can be loosened

with a hand Wrench or a Socket whichever is easier (See

Figure 6). Sometimes it is easier to test fit the Tube End

of Driveshaft to the Pump while the Pump is on the bench,

But this make timing the driveline yokes more difficult.

7.

Install Pump into Splined Clamp Yoke. Coat the

Pump Splined Shaft with Anti-Sieze Compound. Slide the

Pump Splined Shaft into the Spline Clamp Yoke (See

Figure 8). Leave the Bar stuck in through the Yoke as

shown, this helps to stabilize the Yoke as you slide Pump

Shaft into the Yoke. Once Pump is slid into the Splined

Yoke, keep the Pump supported; DO NOT let the Pump

hang on the Yoke unsupported.

8.

Pump / Driveshaft Yoke Gap Adjustment. After

sliding Pump Shaft into Splined Clamp Yoke, the Pump

and Yoke must be slid apart far enough to allow for a 1/16"

to 1/8" Gap between them. The Yoke edge cannot touch

the Pump Housing; it will damage the Housing and the

Yoke if it does. This is a very critical adjustment (See

Figure 9).