Part ii: determining the rotational inertia, Table 4.1: data, 300g mass – PASCO ME-8950A COMPLETE ROTATIONAL SYSTEM User Manual

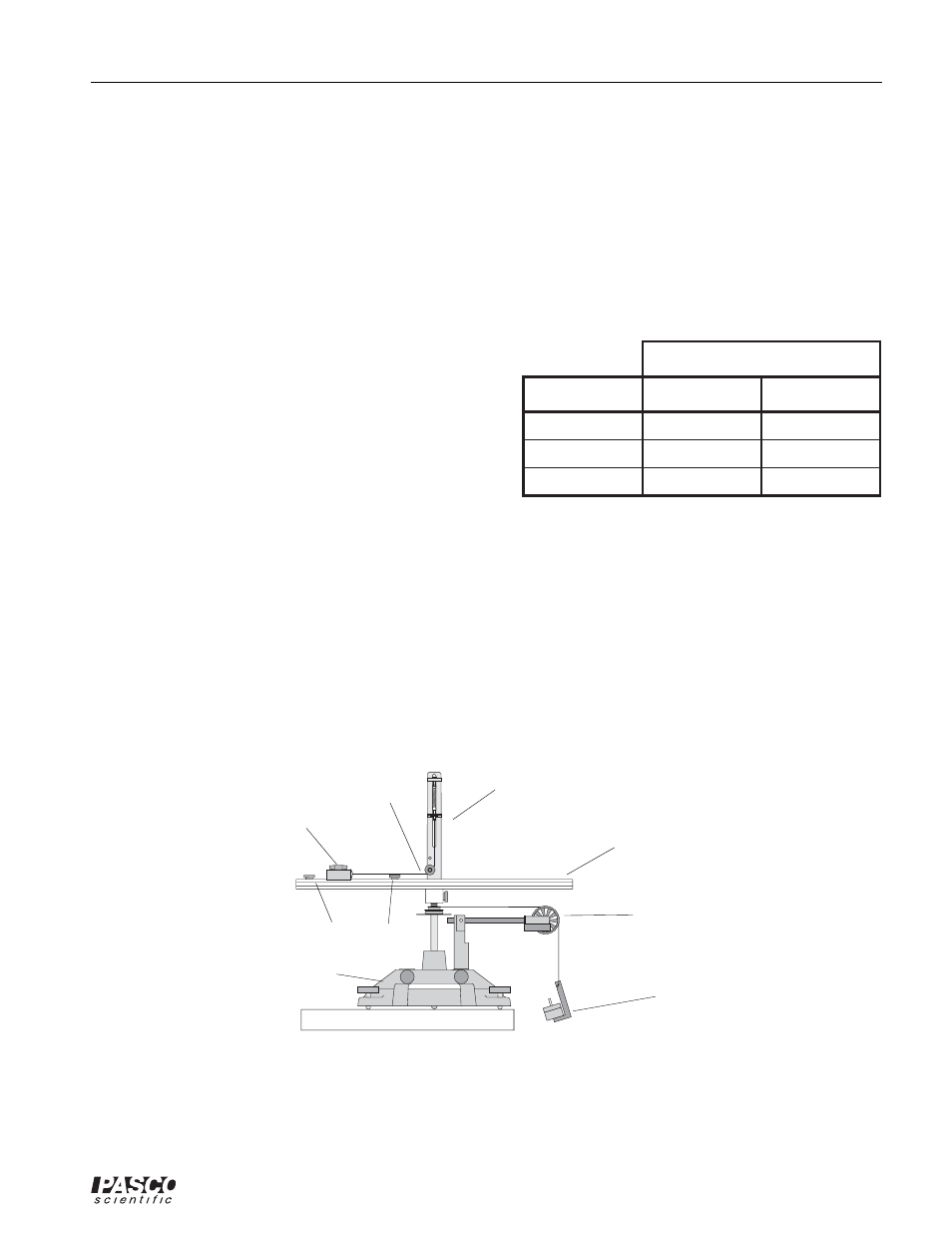

Page 31: Stop screws (2), Center post, String, A" base, Rotating platform, Hanging mass, Spoke pulley with photogate head

012-05293F

Complete Rotational System

27

center post

string

stop screws (2)

Procedure

1.

Select ’Smart Pulley (Rotational)’ as the type of sensor. Set up a Graph display of Velocity (rad/s)

versus time.

2.

Hold the string just above the center post. With the square mass against the outer stop, give the

track a spin using your hand.

3.

Click ’Start’ to begin recording data. After about 20 data points have been taken, pull up on the

string to cause the square mass to slide from the outer stop to the inner stop.

4.

Continue to hold the string up and take about 20 data points after pulling up on the string. Click

’Stop’ to end recording data.

5.

Examine the Graph display of Velocity (rad/s) versus time.

The graph shows the angular speed before and after the

square mass is pulled toward the inner stop. Rescale the

graph if necessary.

6.

Use the Smart Cursor tool to determine the angular speed

immediately before and immediately after pulling the

string. Record these values in Table 4.1.

7.

Repeat the experiment a total of three times with different

initial angular speeds. Record these values in Table 4.1.

Part II: Determining the Rotational Inertia

Measure the rotational inertia of the apparatus twice: once with the square mass in its initial

position and once with it in its final position.

Setup

1.

Attach a Photogate with Pulley to a mounting rod and attach the mounting rod to the black sup-

port rod on the base.

2.

Wind a thread around the pulley on the center shaft and pass the thread over the Pulley. See Fig-

ure 4.3.

Trial Number

Angular Speeds

1

2

3

Initial

Final

Table 4.1: Data

Figure 4.3: Set-up for determining rotational inertia

300g mass

"A" base

rotating

platform

hanging mass

10-spoke pulley with

photogate head