Slide the aluminum cylinder out of the slot, Figure 5 using the driver and detector coils, Manual auto – PASCO WA-9611_13 SONOMETER User Manual

Page 7: Driver coil detector coil

3

012-03489E

Sonometer

➤NOTE: At some lab stations, you may want the

tensioning lever to hang over the left end of the

table instead of the right (see Figure 4). In this case,

you can switch the end plates so that, when per-

forming the experiment, the metric scale will still

be right side up. To switch the endplates:

➀

Loosen the string adjustment screw and remove

the string.

➁

Unscrew the two screws that hold each end plate

onto the sonometer and remove the end plates.

➂

Slide the aluminum cylinder out of the slot.

➃

Slide the cylinder into the slot on the other end

of the sonometer, then switch the end plates.

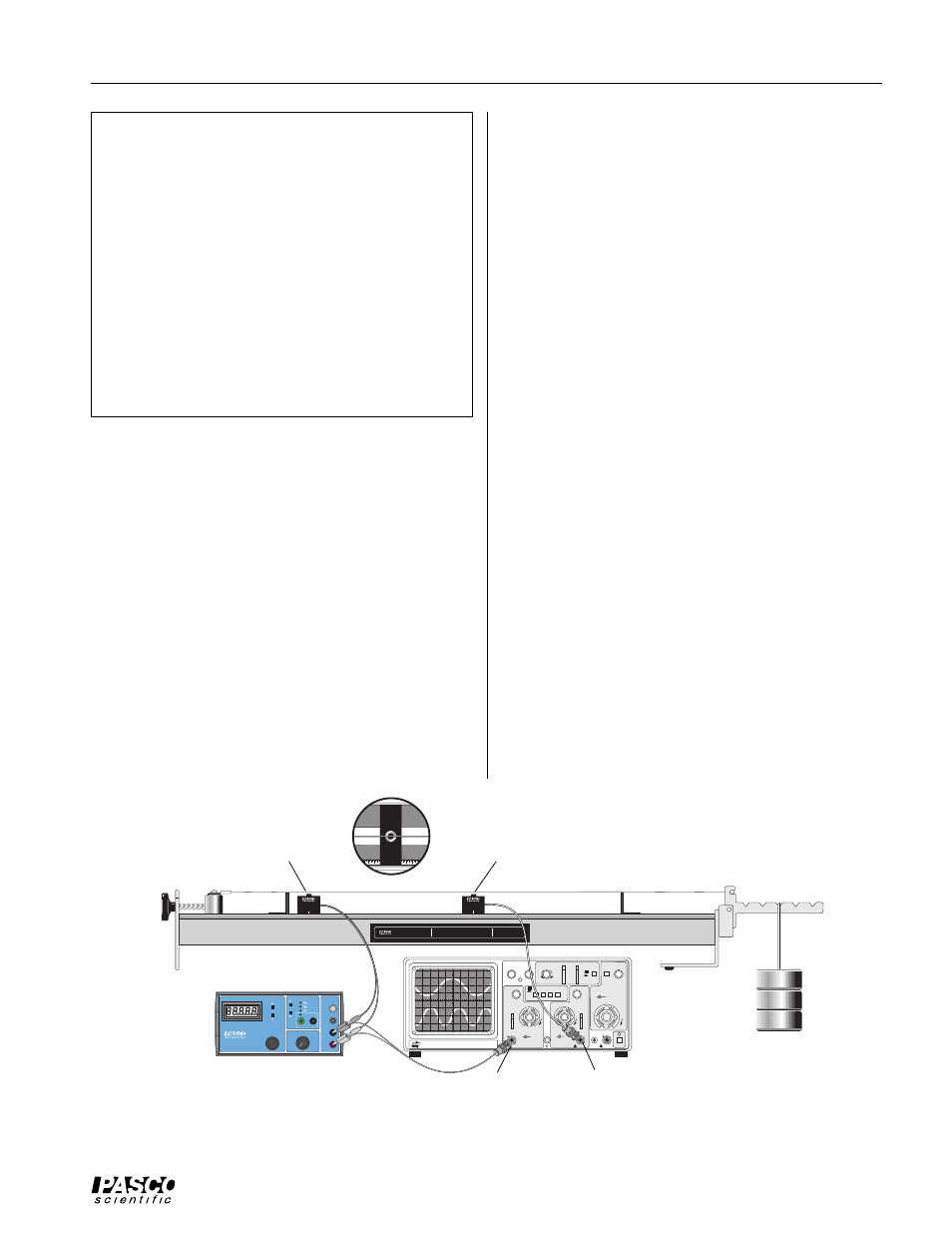

Using the Sonometer and the WA-9613

Driver/Detector Coils:

Sonometer and Driver/Detector Coils with a function

generator and oscilloscope:

➀

Connect the Driver and Detector Coils to the function

generator and oscilloscope as shown in the diagram.

Connect the driver coil directly to the output of the

PASCO PI-9587B Digital Function Generator. Con-

nect the detector coil directly to channel two of an os-

cilloscope that has a BNC connector. You can use ba-

nana plug patch cords and a BNC-to-banana plug

adapter to connect the output of the function generator

to channel one of an oscilloscope that has a BNC con-

nector. (If you are using a single trace oscilloscope,

connect only the detector coil to the oscilloscope.)

➁

Position the driver coil approximately 5 cm from one

of the bridges.

Depending on the wave pattern you are trying to pro-

duce, you might want to place the driver at some other

position. It will drive the string best if it is placed at an

antinode of the wave pattern. However, if you place it

near one of the bridges, it will work reasonably well

for most frequencies.

➂

Position the detector midway between the bridges ini-

tially, though for some patterns you may want to repo-

sition it to best pick up the signal. As with the driver

coil, it works best when positioned near an antinode of

the wave pattern.

➃

Set the gain on channel-one of the oscilloscope to 5

mV/cm. Adjust the oscilloscope so it triggers on the

signal from the function generator.

➄

Set the function generator to produce a sine wave. Set

the frequency to a value between 100 and 200 Hz. Ad-

just the amplitude to about 5 V (approximately half of

maximum). Slowly vary the frequency of the function

generator output. When you reach a resonant fre-

quency, you should see the motion of the string and

the sound produced by the vibrating string should be a

maximum. The wave pattern shown on the oscillo-

scope should become a clean sine wave. If you can’t

see or hear the string, raise the amplitude of the func-

tion generator output slightly and try again.

Figure 5 Using the Driver and Detector Coils

Driver coil

Detector coil

WA-9611

SONOMETER

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

BK PRECISION

200 Mhz OSCILLISCOPE

MODEL

2120

INTENSITY

FOCUS

TRACE NOTATION

TRIG LEVEL

COUPLE

SOURCE

SLOPE

λ

- Y

TIME/DI

V

X-POS

VAR

VAR

VAR SWEEP

CAL

CAL

mV

V

CH 1

VOLTZ/DIV

CH 2

VOLTZ/DIV

CAL

mV

V

VERTICAL MODE

PULL XS

PULL XS

CH 2

∞

CH 1

∞

AC

DC

AC

DC

AC

CH1

CH2

ALT

EXT

POS

POS

NORM

EXT

CH1

CH2

NORM

EXT

CH1

CH2

MANUAL AUTO

T X-

Y

T X-

Y

LINE

CAL

EXT CH4

POWER

200V

MAX

400V

MAX

400V

MAX

-

+

+

-

T T

L

H I

Ω

G

N D

L O

Ω

M I

N

R A

N G E

A D J U

S T

M

A X

O U T P

U T

F R E Q U E N

C Y

A M P L I T U

D E

P I - 9 5 8 7 B

D I G I TA L F U N C T I O N

G E N E R AT O R -

A M P L I F I E R

H E

R T Z

WAV E F O

R M

I N P

U T

G

N D

E X T E R N

A L

DETECTOR

WA-9613

DRIVER

WA-9613

Oscilloscope

Channel 1 (trigger)

Channel 2

Function generator