7repair, Sl repair – Diamond Products SL User Manual

Page 29

7

Repair

7.1

Connection and repair of rope

Do not join ropes with different degrees

of wear:

Difference of the two Ø: max. 0.2mm

(~8 mil)

The rope can be joined or repaired by the follo-

wing locking devices:

–

Joint lock

–

Repair sleeve

–

Threadlock

Needed are:

–

Pressing tongs, sleeve, knife

–

Angular grinder/shearing cutter

additionally for joint lock

–

Mounting kit for joint lock

7.2

Connecting the rope by joint lock

Pressing the lock on

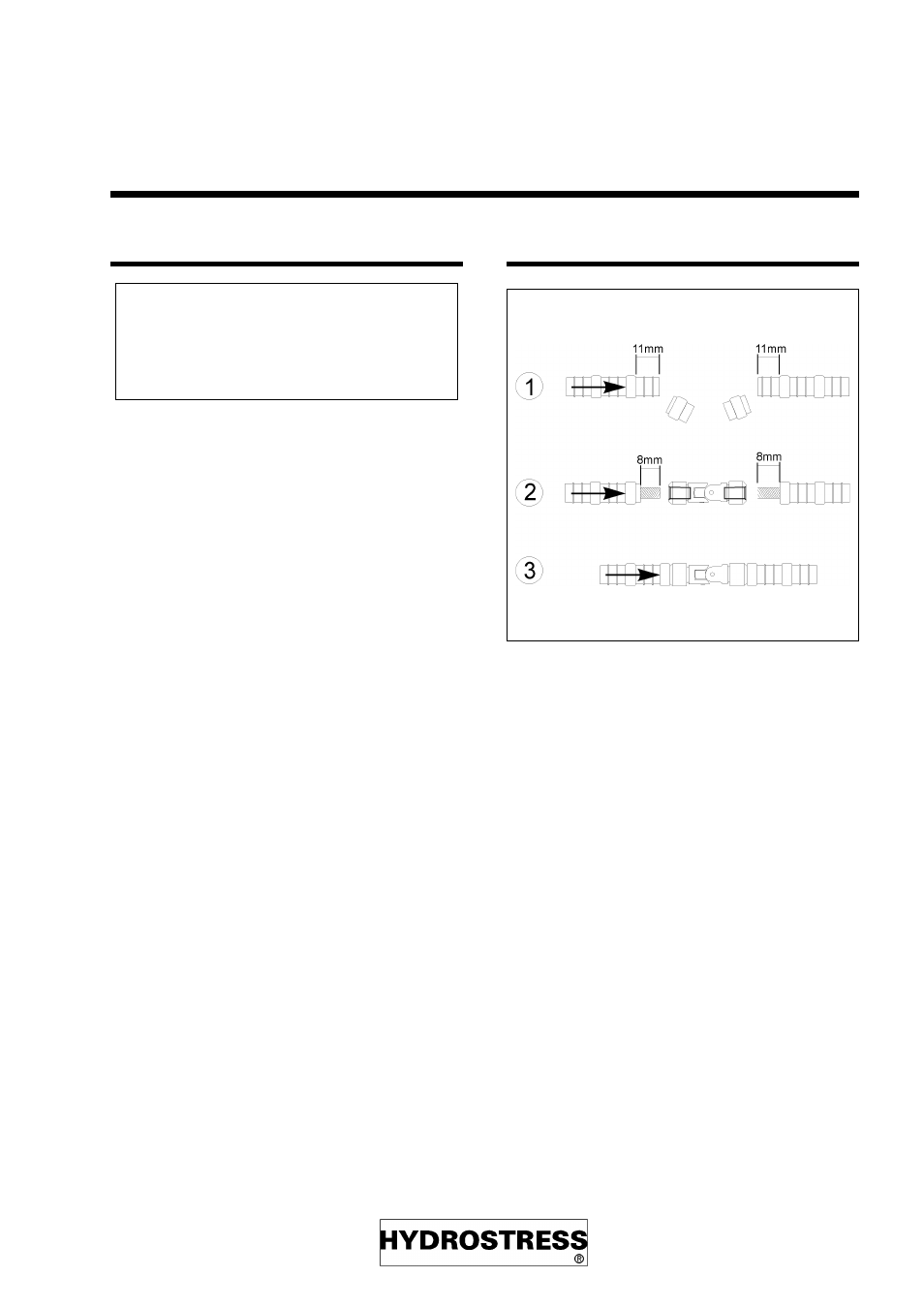

1)

Cut rope at both ends at 11 mm di-

stance from the first bead (Attenti-

on: take care to make a straight cut).

2)

Remove rubber sleeving cleanly by

pulling reinforcement spring off with

pliers, and shorten free rope ends to

max. 8 mm.

3)

Slide loose fork head part of the joint

lock onto the rope end (blank portion

of rope must extend to the bore

dead end)

4)

Press with TYROLIT-Original pres-

sing tongs.

5)

Slide the preassembled lock part

onto the other rope end (similar to

pt. 3)

6)

Press as described under pt. 4

Fig.sk2_glvs.tif

SL

Repair

sl9806e

page 29