Chapter 4-cleaning and inspection, Parts cleaning, O-ring seat -ss option – Magnum Venus Plastech UltraMAX UPLS-2300_UPLS-2300-SS User Manual

Page 27: Parts inspection

MAINTAINENCE AND REPAIR MANUAL

UPLS-2400-SS/2300-SS

MAGNUM VENUS PLASTECH

REV 1.13

APRIL 2010

PAGE 27

CHAPTER 4-Cleaning and Inspection

PARTS CLEANING

Determine which parts are going to be reused and then discard the rest.

All parts can be cleaned in most solvents, when cleaning the Guide Bushing, it is advisable not to let the

part soak in Acetone for any length of time.

Using a wire brush, thoroughly clean all threads and remove residue from all components.

•

Caution: When cleaning the Foot Valve and Piston Body do not damage the Kalrez o-ring

that is on the ball seat.

O-RING SEAT -SS OPTION

In the case of the –SS (Stainless Steel) version of the fluid section, inspect the Kalrez O-ring that is

seated in the Foot Valve and the Piston Body. If possible do not remove, doing so may damage the O-

ring. If the O-ring looks to be in good condition, wipe off will solvent and leave in the Foot Valve/Piston

Body.

If either of these O-rings are damaged and needs to be replaced, it must be ordered separately from the

repair kit or seal kit.

PARTS INSPECTION

After all the parts have been thoroughly cleaned, they need to be inspected. Spending time and money to

repair the entire fluid section will be all for nothing if a faulty part is not replaced and could possibly give

poor performance and/or do further damage to the entire assembly.

Ball Joint Rod End

•

Ensure that the bearing swivels and rotates freely,

Packing Nut

•

Threads must be clean and not marred up.

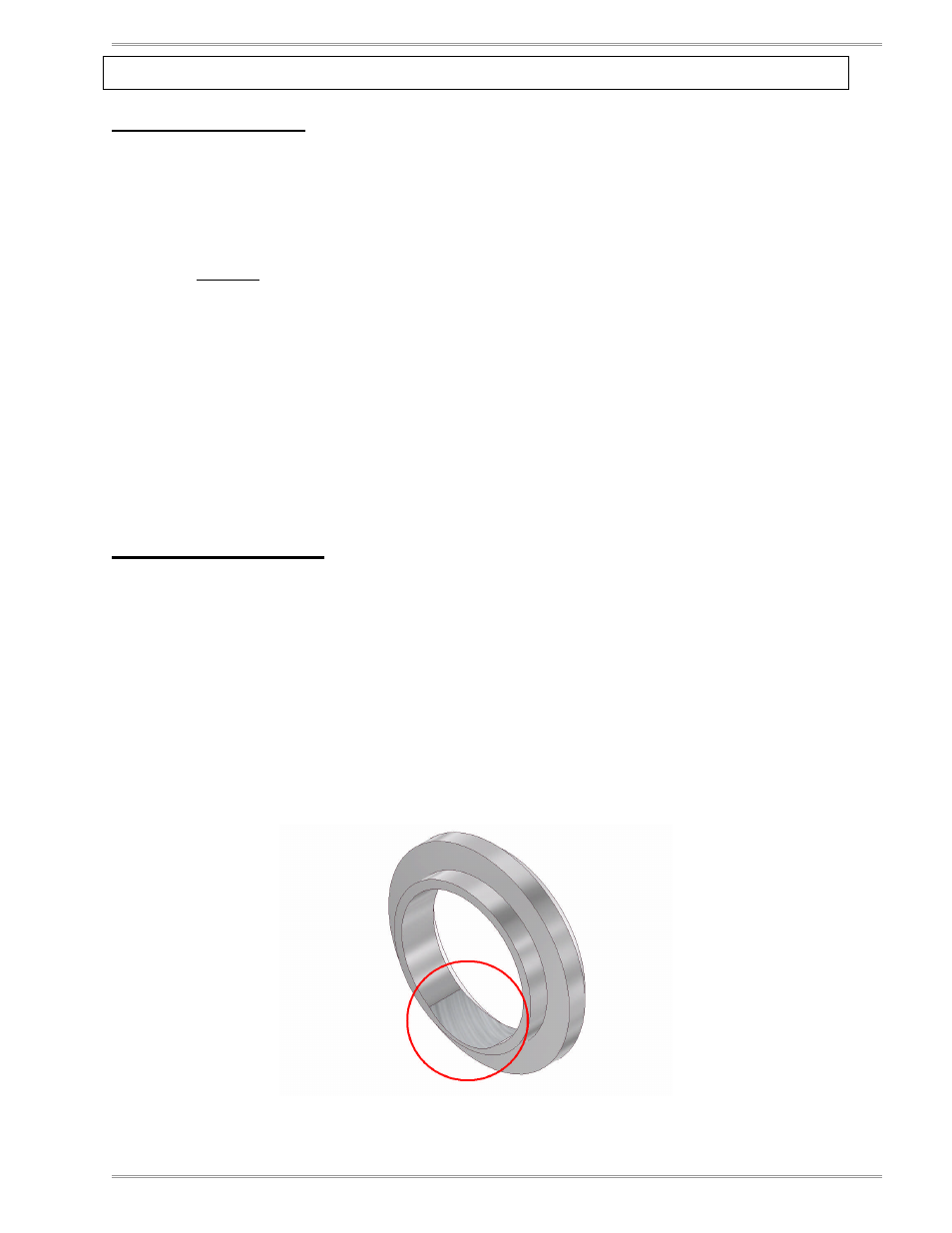

Male Compression Ring and Female Compression Ring

•

Check for wear on inside diameter. (FIG 4.1)

FIG 4.1