Rear view, Analog output option – Liquid Controls SP2200 User Manual

Page 21

19

ANALOG OUTPUT OPTION

Description:

An optional 4-20mA (0-20mA) output has been added to the unit.

The output can be programmed to track C rate or C total.

This feature is available by adding suffix A to the part number.

Connections are via a 2 terminal pluggable screw connector.

Connections: (see FIG. 1)

PIN13 supplies the 12 to 18 VDC to power the current loop.

PIN14 is the control sink driver

Accuracy:

50uA worst case

Compliance Voltage:

3 to 30 VDC non inductive

Setup:

The optional analog output feature uses 4 dip switches on the back

for setup. These switches are used as follows:

SW1 - View or change "set low" and/or "set high" values

SW2 - Select output for rate or total

SW3 - Select 4-20mA or 0-20mA

SW4 - Calibrate the unit.

After the regular parameters shown in the programming flowchart

have been set, locate the 4 switches on the back of the unit. (see

FIG. 1)

Switch Settings:

SWITCH 1: Enter Analog Low & High (normally off)

Switch 1 is used to load in the low (4mA or 0mA) and/or the high

(20mA) output settings. With power on, set switch 1 ON (up).

LOW SETTING is viewed or changed by pressing PRE A. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to the desired value and press ENTER. (disre-

gard the display which will show the last count reading).

HIGH SETTING is viewed or changed by pressing PRE B. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to desired value and press ENTER.

Return switch 1 to OFF (down) position, PRE A and PRE B buttons

now function to view or change relay trip values.

SWITCH 2: Select Count or Rate

SW2 OFF (down): Analog output follows C rate

SW2 ON (up): Analog output follows C count

SWITCH 3: Select 4-20mA or 0-20mA

SW3 OFF (down): Selects 4-20mA output range

SW3 ON (up): Selects 0-20mA output range

SWITCH 4: Calibrate (normally off)

Switch 4 is used for calibration. Calibration is done at the factory

and should not be needed (see SWITCH 1 to enter high and low

values). If recalibration is desired, a calibrated 20mA ammeter

with 1uA resolution is needed. Attach the "+" lead of the meter to

pin 13 and the "-" lead to pin 14. Set switch 4 ON (up). The unit

will output approximately 20.000mA and a decimal will light in the

third position. Read the output using the ammeter. Press PRE A.

If the display is the same as the ammeter reading, press ENTER.

If not, press buttons A through E to step to ammeter reading and

ENTER. (Disregard display which now shows the last count read-

ing with decimal point in third position) Return switch 4 to OFF

(down) position.

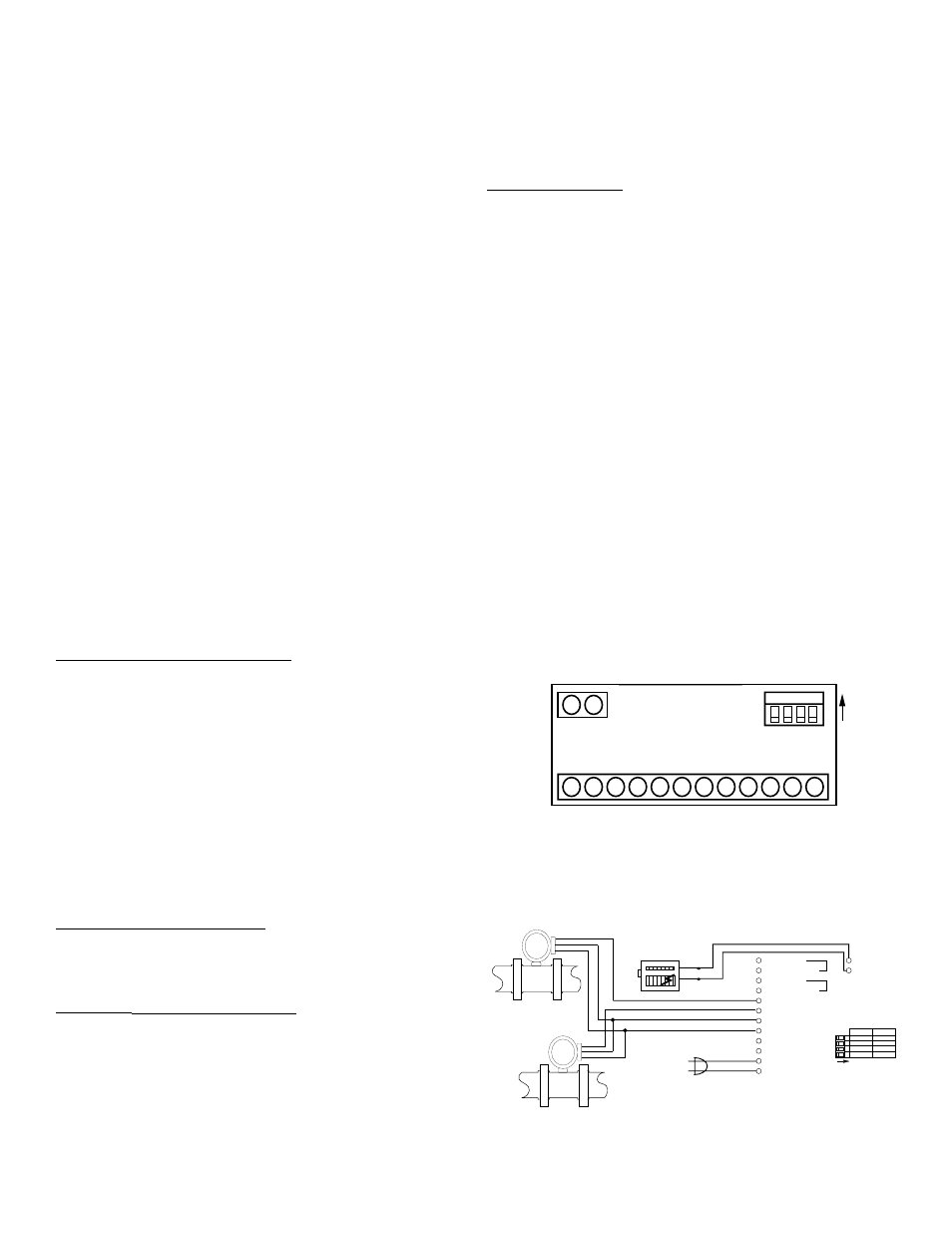

FIG. 1

Typical Wiring:

GND

+12V

STRIP CHART

RECORDER

TURBINE FLOWMETER

PULSE OUTPUT

PULSE OUTPUT

-

+

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- A INPUT

6- B INPUT

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

9- RESET INPUT

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

RELA

YS

A

B

13- V+

14- I SINK

ANALOG

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

ON

SWITCH

TURBINE FLOWMETER

1 2 3 4

REAR VIEW

1 2 3 4 5 6 7 8 9 10 11 12

13 14

Analog Out

Setup Switches

Serial Port

ON