Installation, Receipt of equipment, Return shipment – Liquid Controls SP2850 (MS-649) User Manual

Page 6: Mounting

Sponsler, Inc.

Model SP2850-TC with MS649

Page 6

DOC#: MN-2850

INSTALLATION

Receipt of Equipment:

When the equipment is received, the outside packing case should be checked for damage incurred during

shipment. If the packing case is damaged, the local carrier should be notified at once regarding his liability. A

report should be submitted to the distributor. Carefully remove the equipment from the packing case and inspect for

damage or missing parts.

Return Shipment:

Do not return assembly or part without a Return Material Authorization (RMA). The RMA is obtained by calling your

local authorized distributor.

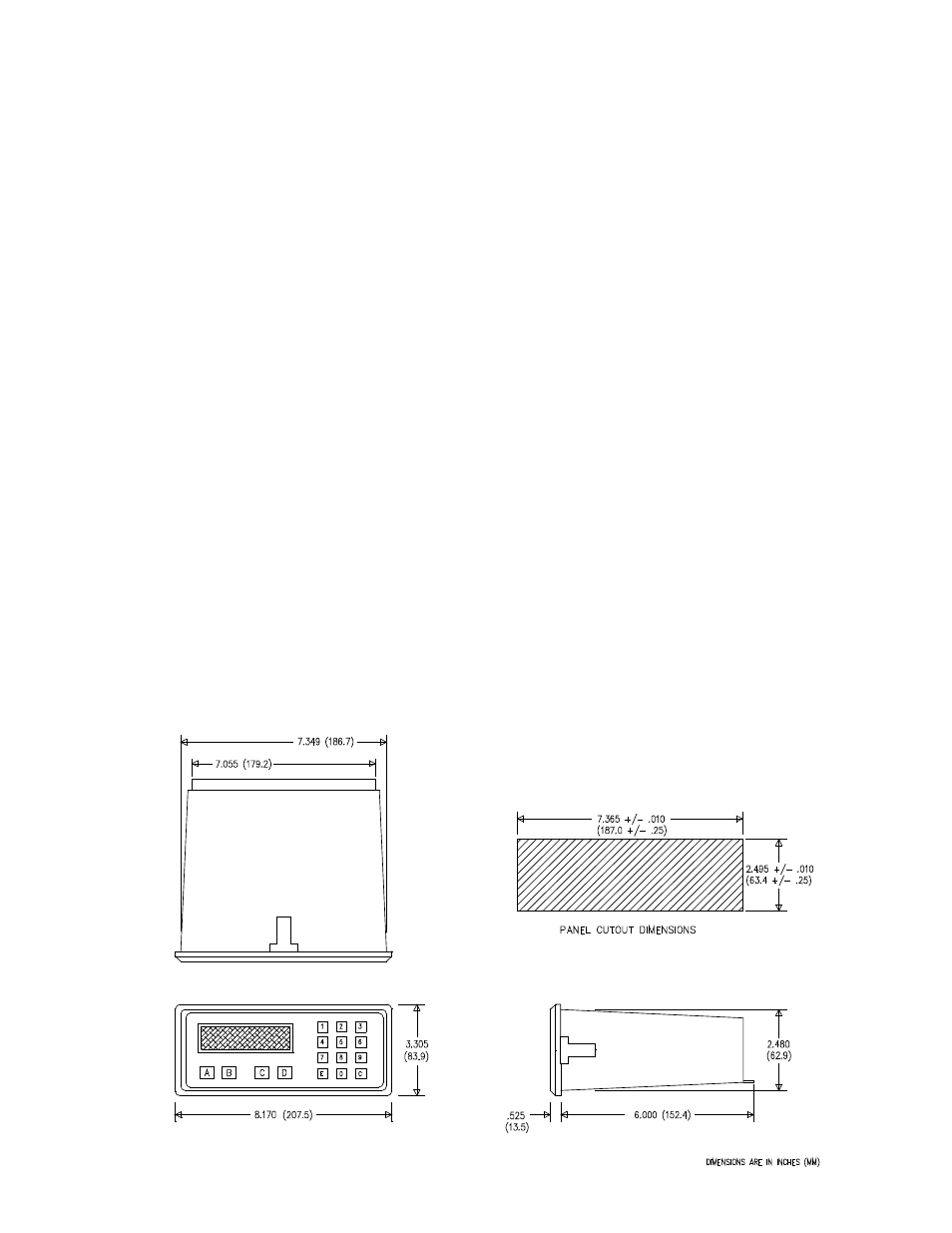

Mounting:

The controller should be located in an area with a clean, dry atmosphere which is relatively free of shock and

vibration. The SP2850-TC is installed in a 7.365” (18mm) wide by 2.495” (63.4mm) high panel cutout. (See

mounting Dimensions) To mount the controller, proceed as follows:

a. Prepare the panel opening.

b. Slip the gasket (provided) over the rear case and slide it forward until it engages the inner surface of the front

bezel.

c. Slide the unit into the panel opening and slide it forward until the panel engages the inner surface of the gasket

at the

front bezel.

d. Install the screws (provided) in the mounting brackets and insert into the mounting holes on top, bottom and

sides of

case.

e. Tighten the screws firmly to attach the bezel to the panel. 3 in. Lb. Of torque must be applied and the bezel

must be

parallel to the panel to maintain NEMA 4 rating.

NOTE: To seal to NEMA 4X specs., supplied gasket must be used and panel cannot flex more than .010”. All 4

clamps must be tightened a min. Of 3 in. Lb. Torque. If panel flex occurs, seal unit with RTV type sealer.