Conveyor Technologies MULTIFLEX User Manual

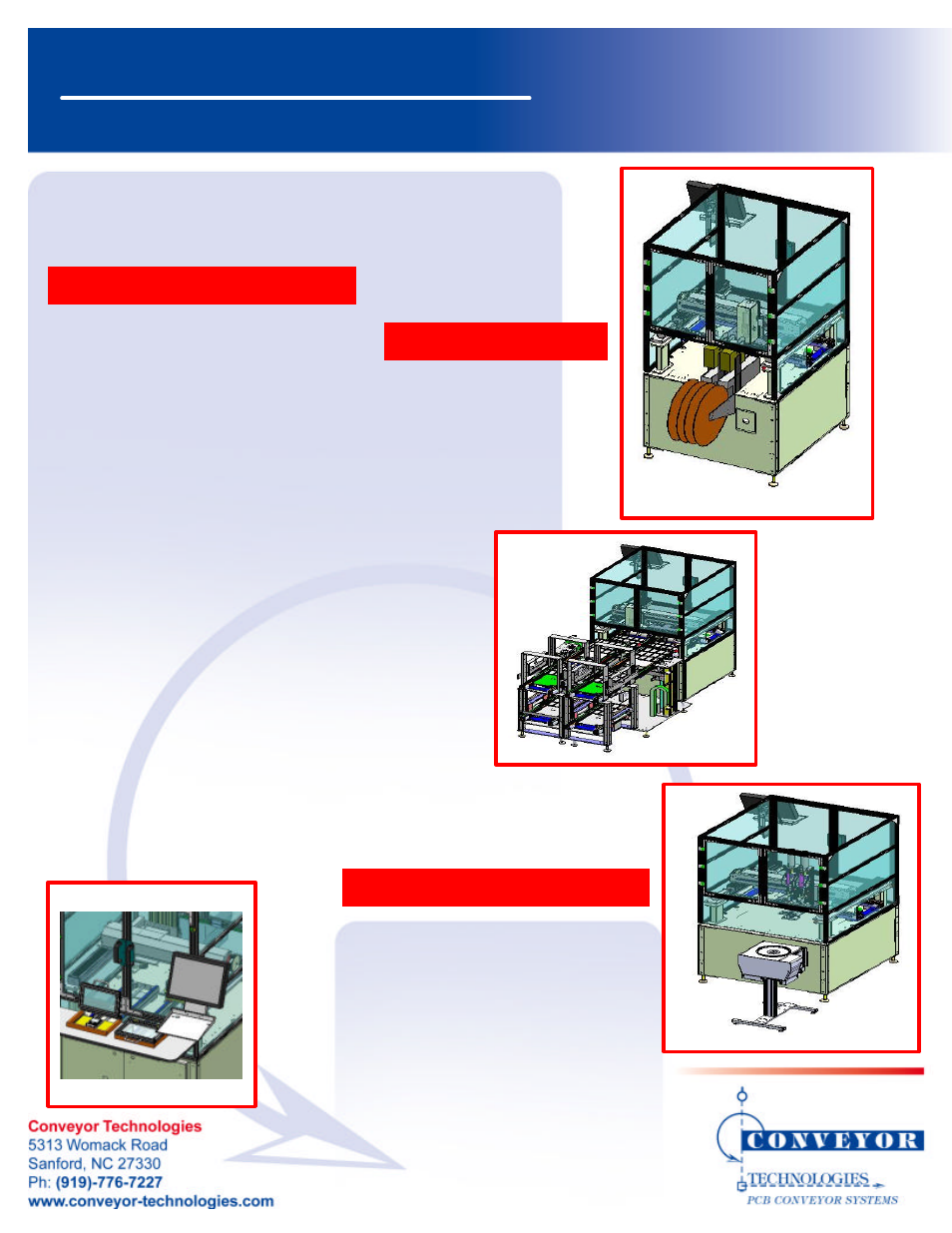

Fx1-1m, Multi-flex machine

· BASE MACHINE

- Heavy Duty Steel Welded Frame

- Front and Rear Access Doors (Interlocked)

- 1 Meter X 1.2 Meter Footprint

• CONVEYOR

- 1 Meter Edge Conveyor

- Hand Crank Width Adjust = 2.0” – 16.0”

- Board Edge Clearance = .100” (.060” min)

- Heavy-duty Aluminum Extruded Rails

- PTB, Wide Belt or Chaku – Chaku Handling (Optional)

• GANTRY

- X-Y-Z Axis Precision Gantry

- Q Axis (Optional)

- 16 X 18" Work Area

- Yaskawa Servo Drives for Each Axis

- THK Slide and Ball Screw Cartesian Gantry Assembly

• VISION

- Fiducial Correction Camera (Optional)

- Component Inspection & Correction (Optional)

• HEAD TOOLING OPTIONS

- Mechanical Vacuum Z-Q Servo Placement

- Mechanical Grippers

- Probe Testers

- Depth / Torque Screw Assembly

- Mechanical Grip Z-Q Servo Insert Press (100 lb.)

- Mechanical Grip Z-Q Servo Insertion Press (5 lb.)

STANDARD FEATURES:

MULTI-FLEX MACHINE

PN:

FX1-1M

STANDARD FEATURES:

The FX1 features a new concept in flexibility unsurpassed in

technology, performance and through put. The FX1 system is

interc hangeable for many operations in a matter of minutes

verses hours.

• SOFTWARE AND CONTROLS

- User Friendly

- Software Platform Includes All Options

- Industrial PC Controls

- Windows Platform

- Recipe and Memory Storage

• FEEDER OPTIONS

- Tape Carrier

- Tray Feeder

- Vibratory Bowl Feeder

- Stick Feeders

Applications:

- Pick and Place

- Screw Driving

- Vision / Inspection

- Tactile Inspection

- Controlled Press