Conveyor Technologies DS-.6M-1 User Manual

Pn: ds m, Stacker pcb

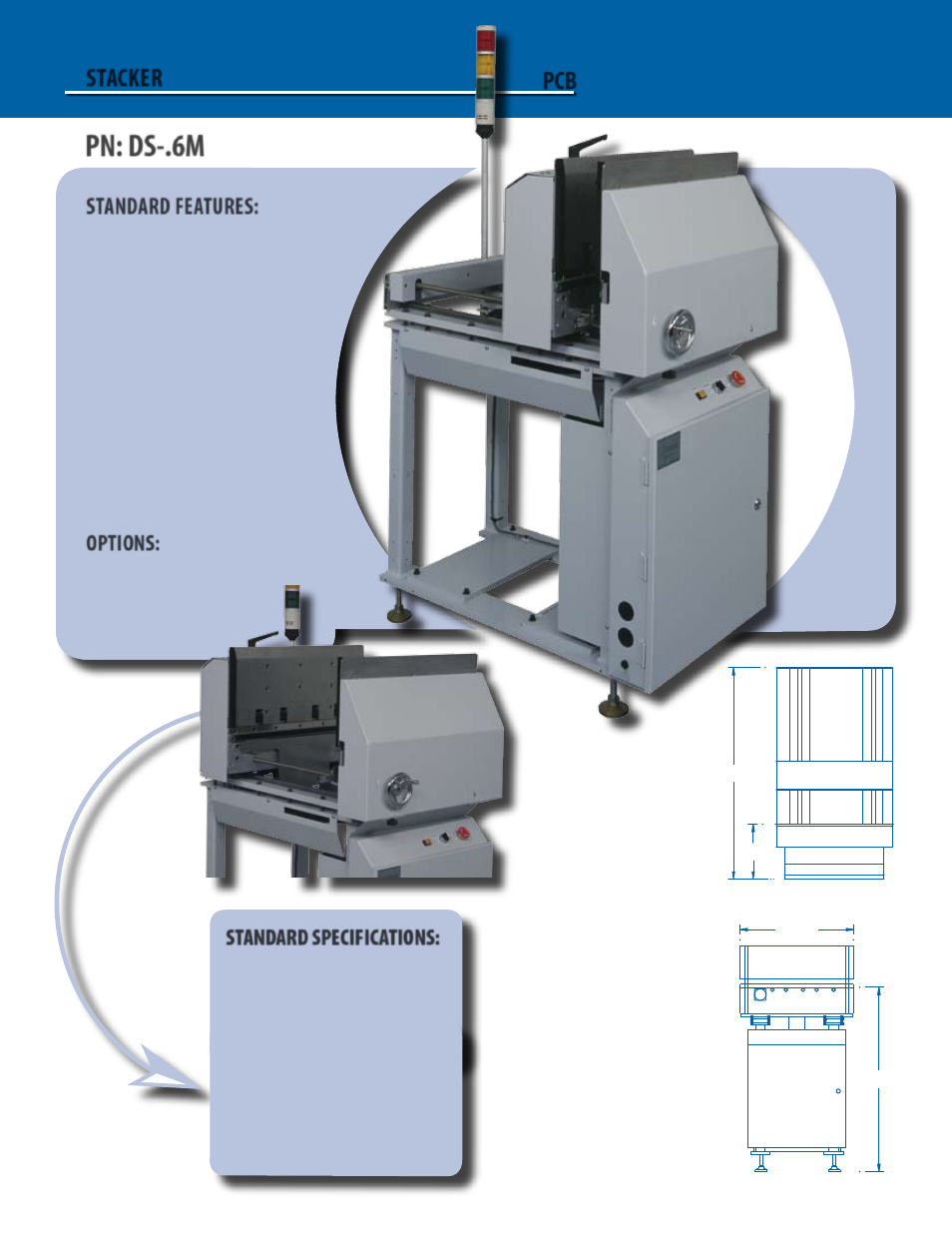

STACKER

PCB

PN: DS-.6M

STANDARD FEATURES:

• Auto/Pass-Thru Switch.

• Mechanical walls apply pressure

against the stack of PCB’s while releas-

ing the bottom PCB to the conveyor

below.

• Protective covers for safety and easy

access

• PLC Controls with SMEMA cables.

• Hand Crank width adjust = 2.” - 16.0”

• Board Edge Clearance = .100” (.060”

min)

• 1⁄2 Inch Steel Welded Frame

OPTIONS:

• Light tower for indicating operating

status

• 18.0” x 20.0” PCB Capability

• CE Compliance

STANDARD SPECIFICATIONS:

PCB Size Min: 2.0” x 5.0”

Max: 14.0” x 16.0”

(Odd shaped PCB’s will not work in this machine)

PCB Height 37.5” + 2”

PCB Clearance Top: = .800”

Bottom: = .500”

Air Consumption .5 cfm @ 65 PSI

Power Supply 110 VAC, 5A

Cycle Time 4 - 6 seconds

Capacity 8 Inch Stack

See also other documents in the category Conveyor Technologies Equipment:

- FMU-72I (1 page)

- MFMU-37I (1 page)

- BMLQ-91I (1 page)

- MBMLQ-55I (1 page)

- FIFO-1.3M-50 (1 page)

- MAG-ALL (1 page)

- MMAG-ALL (1 page)

- BBL-I (1 page)

- BBL-IIB (1 page)

- CC-1M-1 (1 page)

- VLC-6-1M-1 (1 page)

- SCANNER MOUNT CONVEYORS (1 page)

- CW-1M-1 (1 page)

- WORKSTATION OPTIONS (3 pages)

- SG-II (1 page)

- SG-63I (1 page)

- LG-48I (1 page)

- LG-72I-2 (1 page)

- WU-2.5M-2 (1 page)

- FIFO-.6M-21 (1 page)

- FIFO-.8M-30/60 (1 page)

- FIFO-1.2M-60 (1 page)

- SHC-(LENGTH)I (1 page)

- TT-30I (1 page)

- RT/LT-30I (1 page)

- FL-24I (1 page)

- BRC-(LENGTH) (1 page)

- TLTC-.6M-0/15 (1 page)

- WB(WIDTH)-(LENGTH)-(OPTIONS) (1 page)

- HWO-7F-2 (1 page)

- WI-36I (1 page)

- WIET-.6M (1 page)

- RVC-1M-3-LT (1 page)

- CW-AOI-1.2M-2/1 (1 page)

- LASER MARKER-1M (4 pages)

- FULLY AUTOMATED (2 pages)

- SEMI AUTOMATED (2 pages)

- MANUAL (2 pages)

- MANUAL (1 page)

- TUBE FEEDER (1 page)

- AUTOMATIC (2 pages)

- LABEL APPLICATOR (4 pages)

- COMPONENT VERIFIER (2 pages)

- TABLE TOP VISION SYSTEM (1 page)