Hach-Lange AMTAX inter2 Basic User Manual User Manual

Page 104

English 104

to the hose pinch valves and supplies the analysis section constantly

with a current waste water sample. In the measurement operation, the

sample is first delivered via the left-hand pump P1 into the stirrer vessel.

After 120 seconds, the two reagents A and B are additionally dosed in

precisely defined quantities via the right-hand pump P2. After mixing in

the stirrer vessel, the solution flows through the cuvette, the pumps are

switched off and the color reaction begins. In the cuvette, the

ammonium-specific indophenol blue (yellow-green-blue) coloring now

forms; its intensity is photometrically measured using the two-beam,

two-filter method, whereby the influence of the ambient temperature is

electronically compensated for via a temperature sensor.

Calibration (approximately 8 minutes)

An automatic calibration is performed at freely selectable intervals.

Instead of the sample, a null and a standard solution go one after the

other into the stirrer vessel. As part of this two-point calibration, reagent

ageing and dosing fluctuations are compensated for in order to

guarantee as high an accuracy as possible. After each reagent or dosing

hose change, a calibration must be triggered.:

Auto-cleaning (approximately 10 minutes)

Note: Please observe during the handling of the reagents the safety

notes under

section Exchange of the reagents

Note: The cleaning solution LCW 819 has been specially developed for

use in the AMTAX inter 2. Other cleaning solutions that are too strong

attack the hoses and can lead to precipitation!

The cleaning solution specially developed for the AMTAX inter 2 is

supplied ready-made in a transparent 250 mL PE bottle, which allows

the fill level to be clearly identified from outside. It is placed to the right of

the stirrer vessel behind the holder.

Auto-cleaning is performed at freely selectable intervals; it covers the

entire sample path through the device and removes impurities as far as

possible in all affected hoses and glass parts.

Dosing pumps

The two hose dosing pumps used are responsible for the transport of all

fluids. They are stepper motor-controlled and variable in speed and

direction of rotation. The dosing hoses are routed with the help of pump

cassettes via the pump rollers.

Wear on the pump rollers is indicated by strong groove formation, which

can lead to defective dosing. In this case, the exchange of the pump

rollers is recommended as a precaution.

Note: The pump cassettes must be exchanged annually!

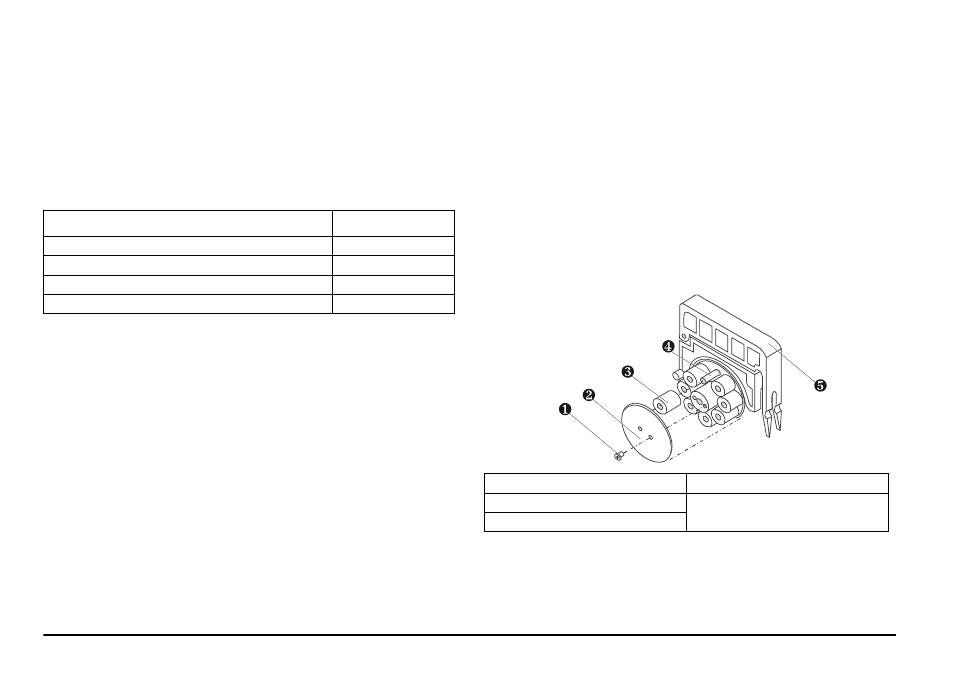

Figure 9 Dosing pump head during roller exchange

Overflow vessel

Note: Please observe during the handling of the reagents the safety

notes under

section Exchange of the reagents

Pump phase

Duration

Purge with sample

120 seconds

Mixture of sample and reagents

40 seconds

Reaction time and average value formation

140 seconds

Waiting time (with 10-minute measurement interval)

300 seconds

1

M3 countersunk screw

4

Cylinder pin (axle)

2

Cover disk

5

Pump cassette

3

Pump roller