Cleaning, If you encounter problems, Replacing the seal – Burkert Type 8011 User Manual

Page 31

31

Maintenanceandtroubleshooting

Type 8011

Warning

risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

9.2.

cleaning

Depending on the nature of the fluid, regularly check for clogging of

the paddle-wheel.

note

the device may be damaged by the cleaning liquid.

• Clean the device with a cloth slightly dampened with water or a

cleaning liquid compatible with the materials the device is made of.

9.3.

if you encounter problems

problem

recommended action

see chap.

The device does not

function

• Check the wiring

• Check that the device is

energized

The pulse output

does not work

Check whether the wiring is

suitable for the output type,

NPN or PNP

The flow rate meas-

urement is incorrect

Recalculate and change the

setting of the K factor

9.4.

replacing the seal

O-ring for metal fitting

O-ring for plastic fitting

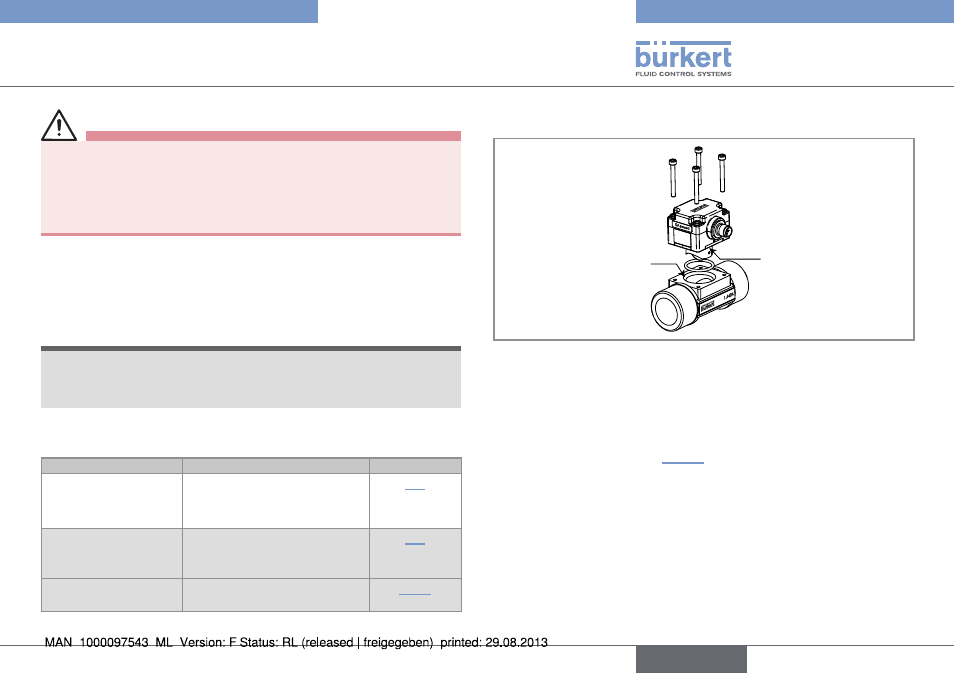

Fig. 14: Exploded view of the 8011

→

Unscrew the 4 screws in the electronic module and remove it

from the fitting.

→

Remove the used seal.

→

Clean the surfaces on which the seal is placed.

→

Insert the new seal (see Fig. 14).

→

Position the electronic module on the fitting so that the arrow

points in the fluid direction on versions with optical sensor.

→

Insert the 4 screws into the electronic module (use the long

screws for a plastic S012, DN6 or DN8 fitting).

→

Tighten the 4 screws in an alternating pattern, to a torque of

1.5 Nm.

English