2 cleaning and recalibration at the factory – Burkert Type 8741 User Manual

Page 31

31

Maintenance

Type 8741

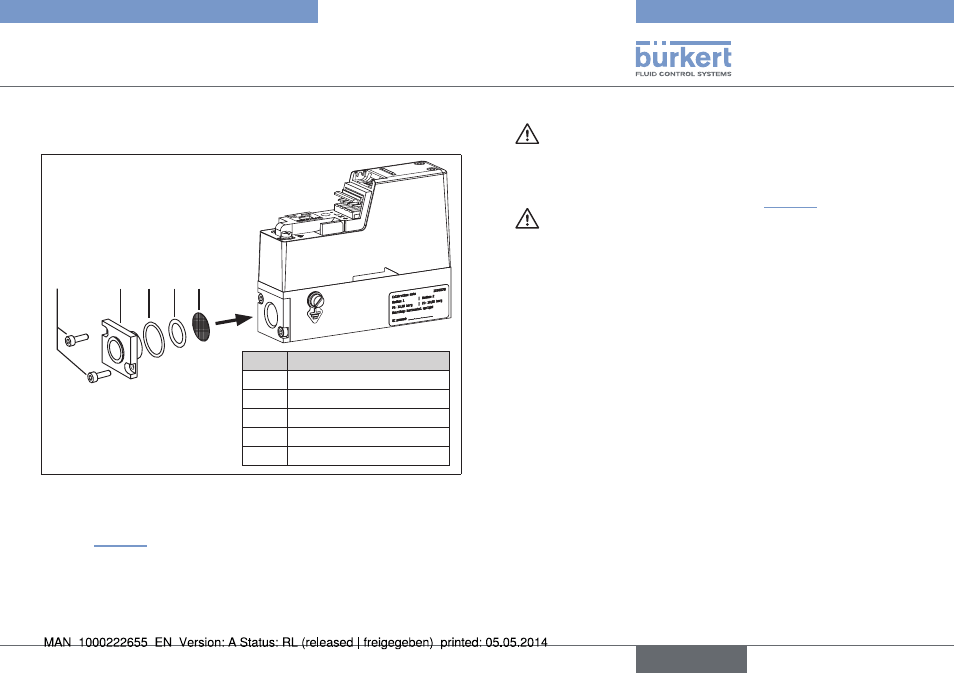

10.1.1 cleaning the stainless steel mesh

filter

1

2

3

4

5

item

description

1

Screw

2

Inlet flange plate

3

O-Ring

4

O-Ring

5

Stainless steel mesh filter

Fig. 19 : Cleaning the stainless steel mesh filter

→

Remove the inlet flange plate [2] by loosening the two screws [1]

(see "Fig. 19").

→

Remove the O-ring [4] and the stainless steel mesh filter [5].

→

Clean the stainless steel mesh filter [5].

Do not clean with tap water!

Clean with acetone, isopropanol or compressed air.

→

Dry the stainless steel mesh filter after cleaning.

→

Install the parts in the correct order (see "Fig. 19").

The fine side of the stainless steel mesh filter [5] must face

the inlet flange plate [2].

Before tightening the inlet flange plate, make sure that the

stainless steel mesh filter and the O-rings and seated flat and

not tilted.

→

Screw on the inlet flange plate [2].

10.2 cleaning and recalibration at the

factory

If the sensor is contaminated or damaged by operation, it may be that

the signal for the mass flow rate no longer corresponds to the actual

mass flow rate.

In this case the sensor must be replaced and recalibrated by the

manufacturer.

English