4 fluid system installation – Burkert Type 8741 User Manual

Page 18

18

Installation

Type 8741

7.4

fluid system installation

Danger!

danger due to high pressure in the installation/device.

▶ Before working on the installation or device, cut the pressure

and vent and drain the pipes.

Select the fluid connections according to the maximum mass flow rate.

No inlet section is required.

On request, the device can be supplied with the fluid connections fitted.

Warning!

danger due to leakage!

At low mass flows and high pressures, particular attention must

be paid to the tightness of the system in order to prevent incorrect

metering or leakage of the operating medium.

To ensure a secure seal

▶ Install the fittings without subjecting them to any stresses

▶ Use compression fittings to ensure sealing of the system.

▶ Use a pipe with a suitable diameter and a smooth surface.

procedure:

The fluid connection was, as an example, declared relating to the

front of the device but also applies to the connection on the rear of

the device.

→

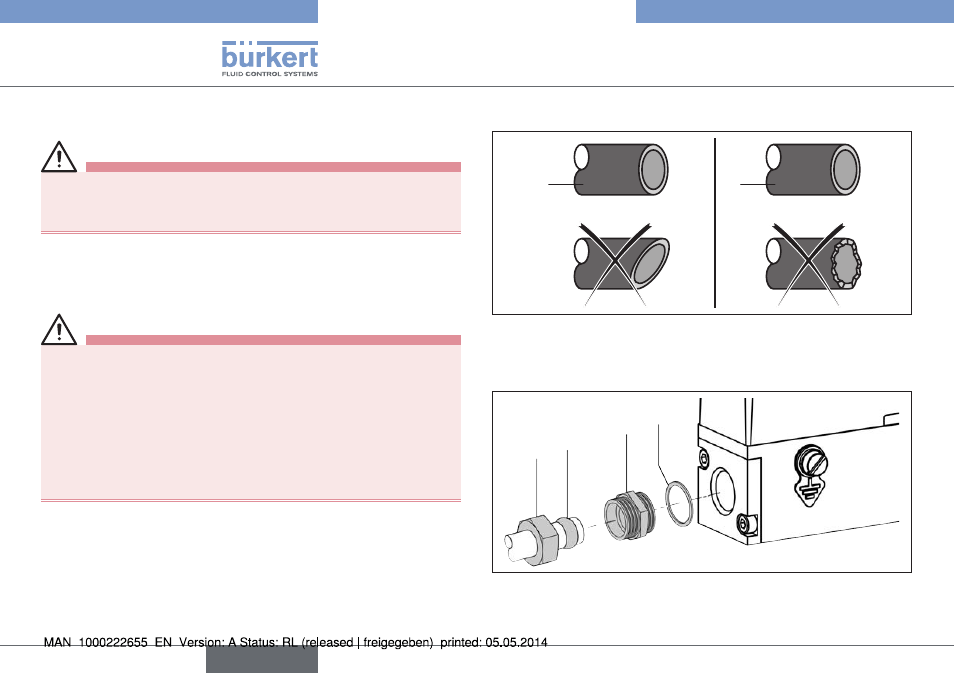

Cut the pipe squarely [1] and deburr [2].

1

2

Fig. 6 : Cutting the pipe and deburring

→

Remove the protective cap with which the port is closed.

→

Slide the union nut [a] and then the clamping ring onto the pipe.

a

Clamping

ring

B

c

Fig. 7 : Slide the union nut and clamping ring onto the pipe.

English