Adjustment to the valve and application data – Burkert Type 8605 User Manual

Page 14

14

Configuration and Function

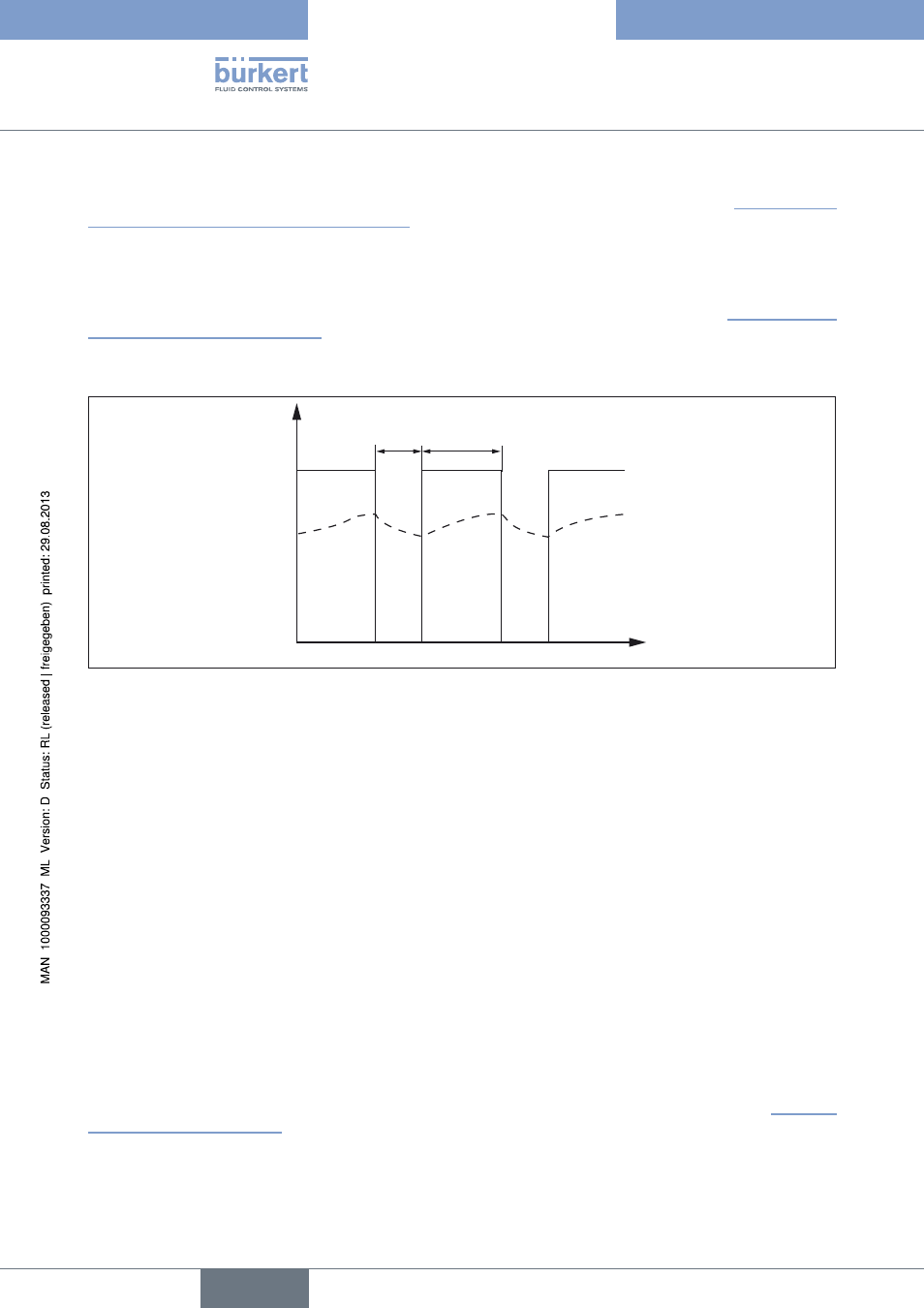

Due to the inductivity of the coil, the rectangular time curve of the PWM voltage signals is not transformed into a

corresponding current curve; instead the coil current has a sawtooth like „rounded“ time curve (see “Figure 6: Time

response of PWM voltage signal and coil current”). The mean (effective) coil current over time depends on the pulse

duty factor τ of the voltage signal.

τ = t

on

/(t

on

+ t

off

)

The curve of the coil current in the cycle of the PWM frequency generates a proportional change in the magnetic

force acting on the armature and hence, with an appropriate choice of this frequency (see chapter “7.3. Adjustment

to the Valve and Application Data”), a steady slight movement of the armature about its momentary equilibrium

position (dither movement). This avoids static friction effects at the bearing points.

t

off

t

on

t

U

I

Figure 6:

Time response of PWM voltage signal and coil current

Due to the intrinsic heating of the coil and the associated large changes in resistance of the winding, the coil current

and hence the opening of the valve with a fixed pulse duty factor do not remain constant. An internal current control

system serves to compensate these thermal effects by corresponding tracking of the pulse duty factor.

7.3.

Adjustment to the Valve and Application Data

The working range of a valve in a particular application depends greatly on its nominal size and the prevailing pressure

conditions.

In order to adapt the working range optimally to the range of the control signal, the key values for the effective coil

current are set via the operating unit in such a way that:

• the opening of the valve starts at a current value slightly above the lower key value (I

1

) and

• the full flow rate is achieved at a current value slightly below the upper key value (I

2

).

The lower key value is the current controlled at the lowest value of the standard signal (0 V, 0 mA or 4 mA).

The upper key value is obtained at the maximum value of the standard signal (5 V, 10 V or 20 mA).

Between the two key values, the effective coil current has a linear relationship to the input signal (see “Figure 7:

Current over standard signal”)

english

Type 8605