Burkert Type 2036 User Manual

Page 17

17

Malfunctions

Type 2036

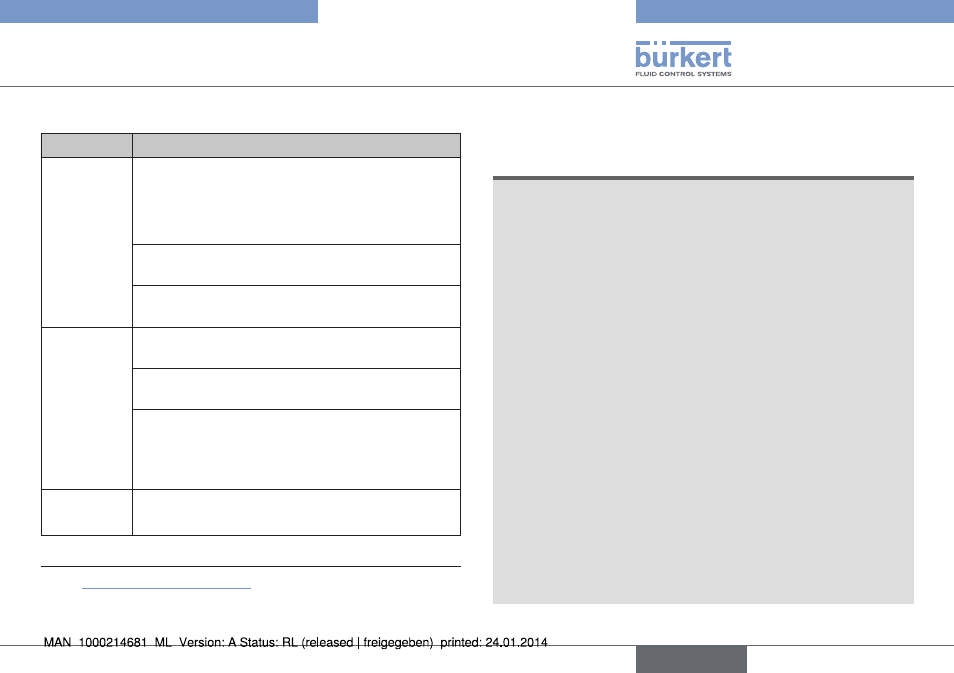

11 MalfuncTions

malfunction cause / remedial action

Actuator

does not

switch.

Pilot air port interchanged

5)

CFA: Connect the pilot air port 1 and/or 3

CFB: Connect the pilot air port 2 and/or 4

Pilot pressure too low

See pressure specifications on the type label.

Medium pressure too high

See pressure specifications on the type label.

Valve is not

sealed.

Medium pressure too high

See pressure specifications on the type label.

Pilot pressure too low

See pressure specifications on the type label.

Actuator is rotated by 90° and installed opposite

the valve body.

→

Guide pin, identification plate and body seats

must be aligned in parallel.

Flow rate

reduced.

Diaphragm bulging

→

Replace diaphragm.

Tab. 4: Malfunctions

5)

see "Fig. 8: Pneumatic connection".

12 TransPorT, sToraGe,

PackaGinG

note!

transport damage.

Inadequately protected devices may be damaged during

transportation.

▶ Protect the device against moisture and dirt in shock-resistant

packaging during transportation.

▶ Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

▶ Protect the pneumatic connections from damage by placing

protective caps on them.

incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature 0 – +60 °C.

if the device is stored with tightened body screws, the dia-

phragm may be permanently deformed.

▶ If the device is stored for a prolonged period, slacken the body

screws.

damage to the environment caused by device components

contaminated with media.

▶ Ensure that the device and packaging are disposed of in an

environmentally sound manner.

▶ Observe applicable disposal and environmental regulations.

english