Burkert Type 2036 User Manual

Page 12

12

Assembly

Type 2036

6.2.2 Preparatory work

→

Clean pipelines (sealing material, swarf, etc.).

→

Support and align pipelines.

devices with welded body

note!

damage to diaphragm or actuator.

▶ Before welding in the body disassemble the actuator and

diaphragm.

Remove the actuator from the valve body:

→

Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

→

Mark the position of the actuator in relation to the valve body.

→

Unscrew the four body screws that connect the valve body with

the actuator. Remove the actuator and the diaphragm.

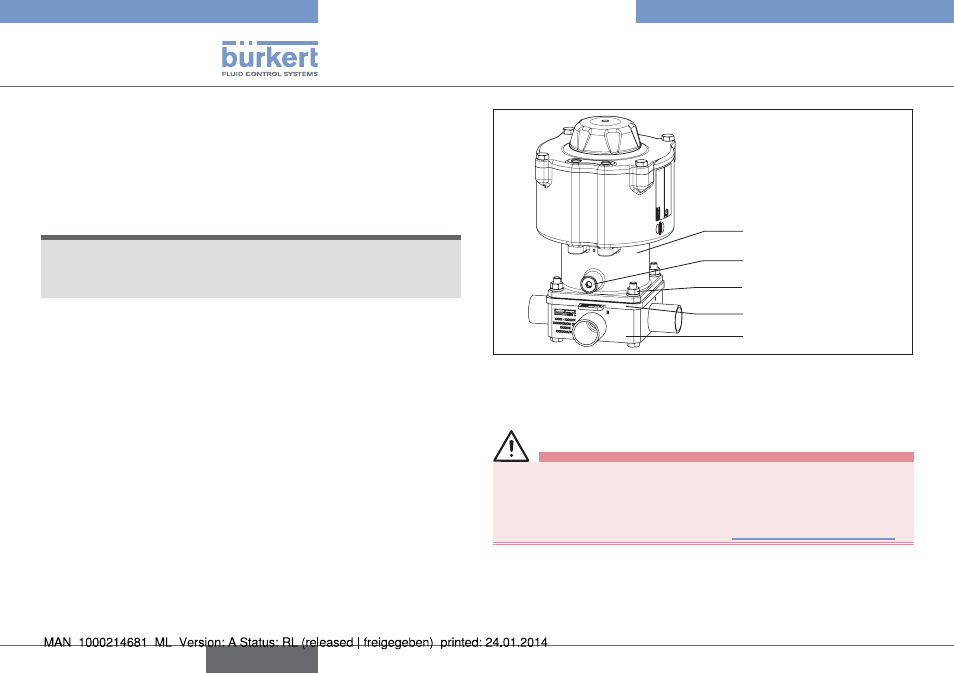

Actuator

Body screws

Diaphragm

Valve body

Guide pin

Fig. 6:

Assembly

6.3 installation

Warning!

risk of injury from improper assembly.

Non-compliance with the tightening torques is dangerous due to

possible discharge of medium and possible release of pressure.

▶ Observe the tightening torque (see "Tab. 2: Tightening torque").

english

- Type 0125 (15 pages)

- Type 0121 (4 pages)

- Type 0330 (2 pages)

- Type 0331 (4 pages)

- Type 6012 (4 pages)

- Type 0127 (18 pages)

- Type 0131 (5 pages)

- Type 0141 (5 pages)

- Type 0142 (12 pages)

- Type 0145 (3 pages)

- Type 0174 (5 pages)

- Type 0212 (2 pages)

- Type 0211 (5 pages)

- Type 0212-B (18 pages)

- Type 0250 (64 pages)

- Type 0253 (2 pages)

- Type 0255 (15 pages)

- Type 0355 (2 pages)

- Type 0255 (2 pages)

- Type 8006 (34 pages)

- Type 8640 (2 pages)

- Type 8640 (55 pages)

- Type 8640 (119 pages)

- Type 0256 (15 pages)

- Type 0256 (2 pages)

- Type 0258 (72 pages)

- Type 0262 (5 pages)

- Type 0273 (6 pages)

- Type 0280 (5 pages)

- Type 0280 (2 pages)

- Type 0280 (12 pages)

- Type 0281 (2 pages)

- Type 0282 (2 pages)

- Type 0283 (2 pages)

- Type 0286 (4 pages)

- Type 0287 (15 pages)

- Type 0290 (2 pages)

- Type 0290 (14 pages)

- Type 0293 (18 pages)

- Type 0300 (6 pages)

- Type 0301 (6 pages)

- Type 0311 (2 pages)

- Type 0312 (6 pages)

- Type 6519 (3 pages)

- Type 6519 (4 pages)