Burkert Type 2080 User Manual

Page 5

english

16

8. insTallaTiOn

8.1. safety instructions

Warning!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians

only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

8.2. fluid installation

Danger!

Danger – high pressure!

Serious risk of injury when reaching into the equipment.

• Before loosening the lines and valves, turn off the pres-

sure and vent the lines.

Check that the operating conditions correspond

with the performance data of the device.

english

17

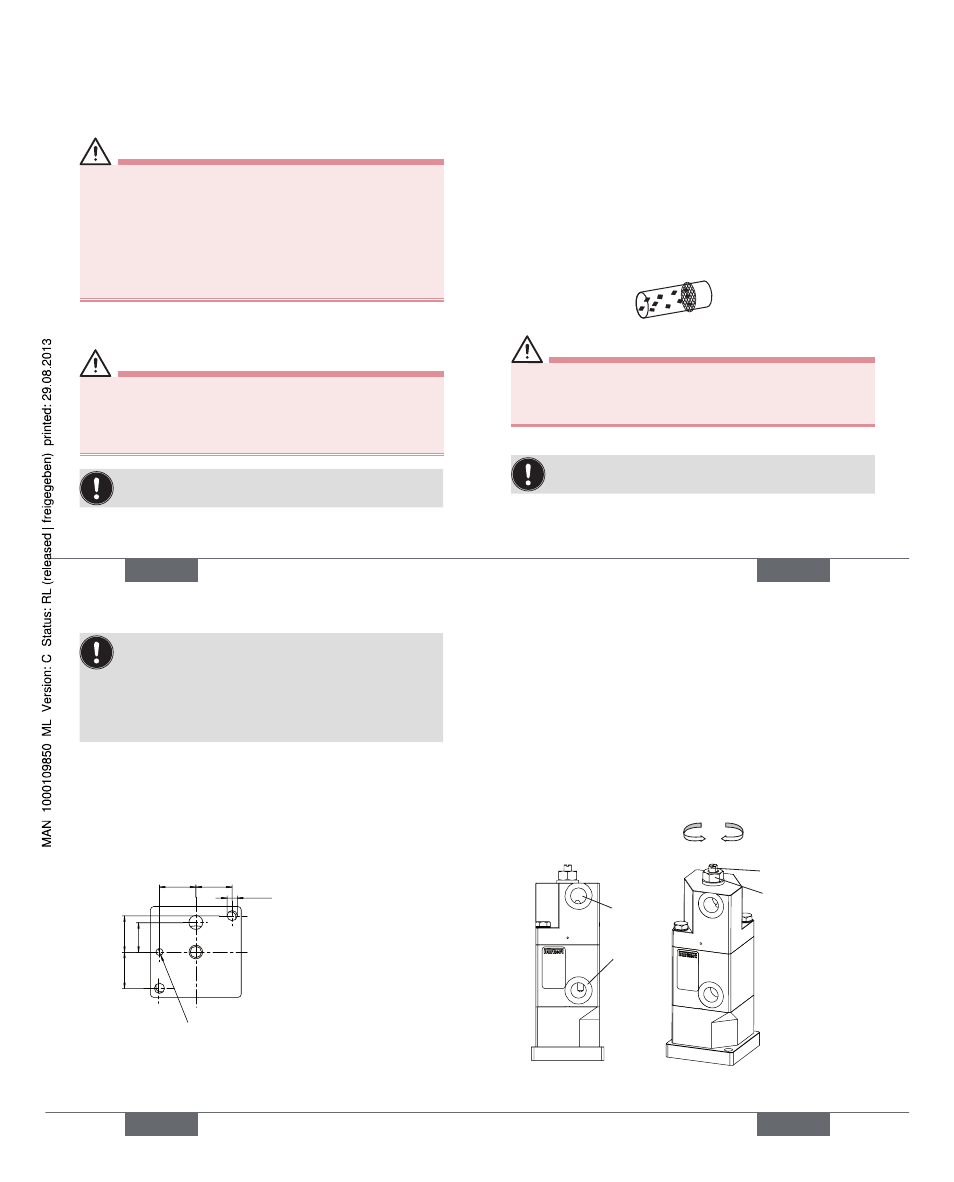

Installation position:

Installation can be in any position.

→

Install upright for self-draining (body to bottom and in

the case of threaded port and welded ends install at a

min. gradient of 1° for drainage of media).

Installation

→

Before installation, clean any possible dirt off the pipelines

and flange connections.

→

If necessary, install a dirt trap in front of the valve to protect

it from malfunctions.

Mesh size:

0.1 ... 0.4 mm

Warning!

Danger - escaping medium!

Leaky connections with seals not properly seated.

• Fit all connections carefully and seal properly.

Seal the threaded port with a suitable sealing

material (PTFE tape is recommended).

english

18

Use the correct size of open-ended wrench to

screw in the pipelines; do not use the valve actuator

as a screwdriver!

The device must not be subject to any lateral

tension forces. The device connections must be in

alignment with the lines!

→

Attach the valve according to the connections:

Threaded port by screwing in the pipes,

Welded connection by welding,

Flange by screwing on.

Flange interface on the valve

16

16

Ш 4.5

Ш 3.1; 6 deep;

Option for positioning pin ø 3

(ensure correct location for installation)

16

16

13

english

19

8.3. Option: Valve with 3 position

actuator (with adjustable

intermediate position)

Functions of the valve:

• Closed (without pilot air, by spring force),

• Partial stroke (pilot air simultaneously on X and Y),

• Full stroke (pilot air on X only).

Adjusting spindle

Lock nut

Stroke setting on the spindle

Flange version

Y

X

Flow

plus minus

Type 2080