Burkert Type 2080 User Manual

Page 3

english

8

5. general infOrmaTiOn

5.1. contact address

germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (0)7940 - 10 91 111

Fax: +49 (0)7940 - 10 91 448

E-mail: [email protected]

international

Contact addresses can be found on the final pages of the

printed operating instructions.

And also on the internet at:

www.burkert.com

5.2. Warranty

The warranty is only valid if the device valve Type 2080 is

used as intended in accordance with the specified application

conditions.

5.3. information on the internet

The operating instructions and data sheets for Type 2080 can

be found on the Internet at:

www.burkert.com

english

9

6. sTrucTure and funcTiOn

6.1. modularity

The valve is modular in design and can be supplied with

different media connections (also customized) and actuator

versions according to the application case. It can be used

individually and also in blocks.

6.2. structure

The valve consists of a pneumatically actuated piston actuator

with return spring, a stainless steel body and PTFE bellows.

The bellows are used to separate media. If the installation

location is appropriate, the valve is self-draining.

The materials used and the inner contours facilitate cleaning

(CIP/SIP).

The pneumatic actuator must be controlled externally via a

pilot valve or a valve island.

english

10

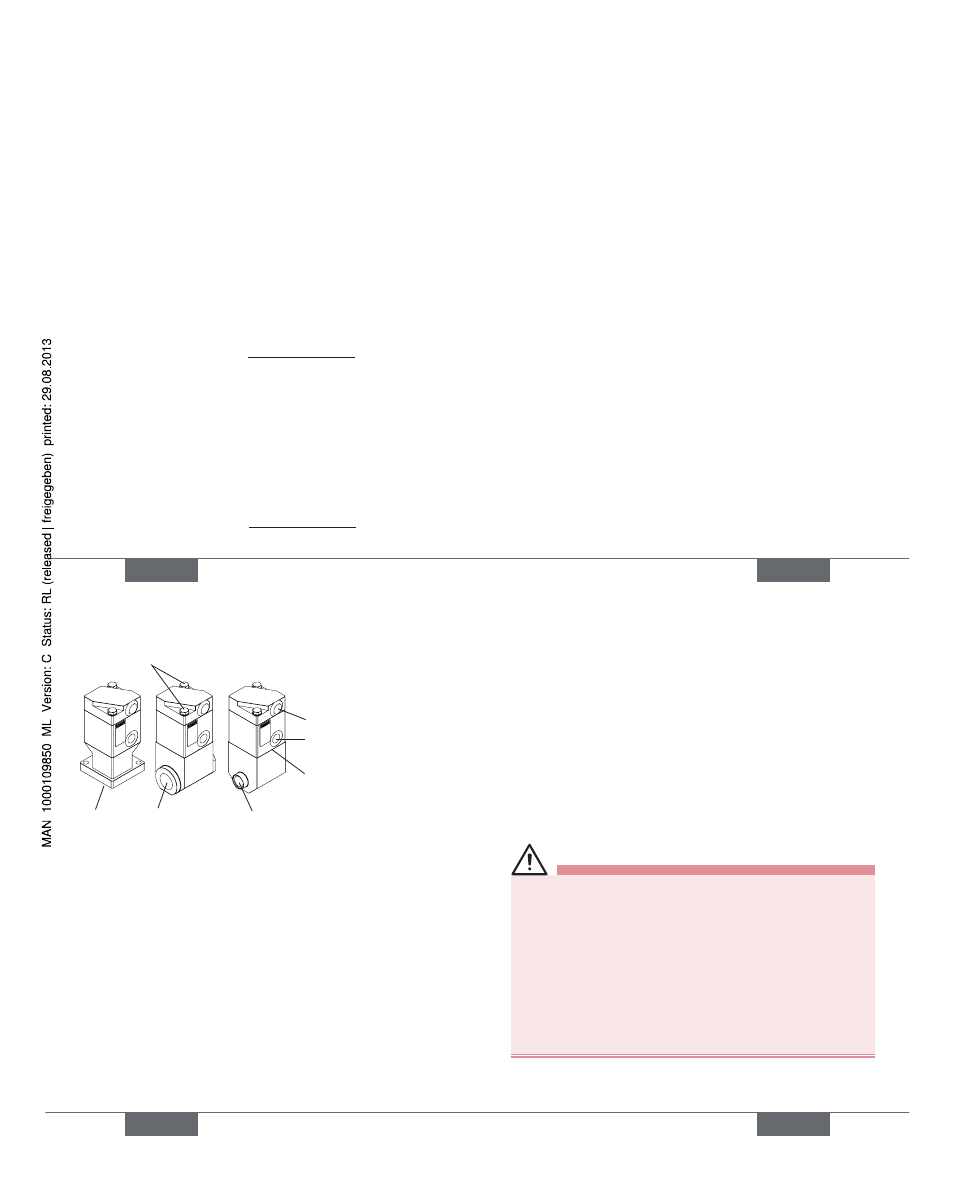

Bolts for attaching the

actuator to the body

Pilot air connections

Threaded ports G 1/8

Connection CF B (NO)

Connection CF A (NC)

Flange

Threaded port Welded end

G 3/8

Media connections

Notch for monitoring of

bellow leakage

english

11

7. Technical daTa

7.1. Operating conditions

Ambient temperature

-10 ... +90 °C

Medium temperature

-30 ... +150 °C

(see PT graph)

Media

Neutral to aggressive gases

and liquids, technical vacuum

7.2. restrictions

For Valves with a flow inlet over seat:

Warning!

Risk of injury from water hammer.

If flow inlet over seat with liquid media, water hammers may

occur. As a consequence, lines or the device may burst

and medium flow out.

• Consider the type of flow inlet and the type of medium

for operation of the device.

• If flow inlet over seat before the use of liquid media,

to avoid water hammers, in case of doubt, clarify the

application conditions (medium, line length and cross-

section) with the Bürkert sales office.

Type 2080