Flomega, liquid mfc’s/mfm’s, Warning – Brooks Instrument 5882/92 User Manual

Page 23

23

Installation and Operation Manual

X-TMF-FM-MFC-eng

PN 541-C-007-AAG

April, 2008

Flomega, Liquid MFC’s/MFM’s

4-3

Trouble Shooting Guidelines

General

Before applying power, remove cover of the housing and check jumper setting (see calibration sheet), and

make sure that the valve connector has been fixed correctly (Controller only.) After applying power, wait at

least 35 minutes to allow the unit to warm up.

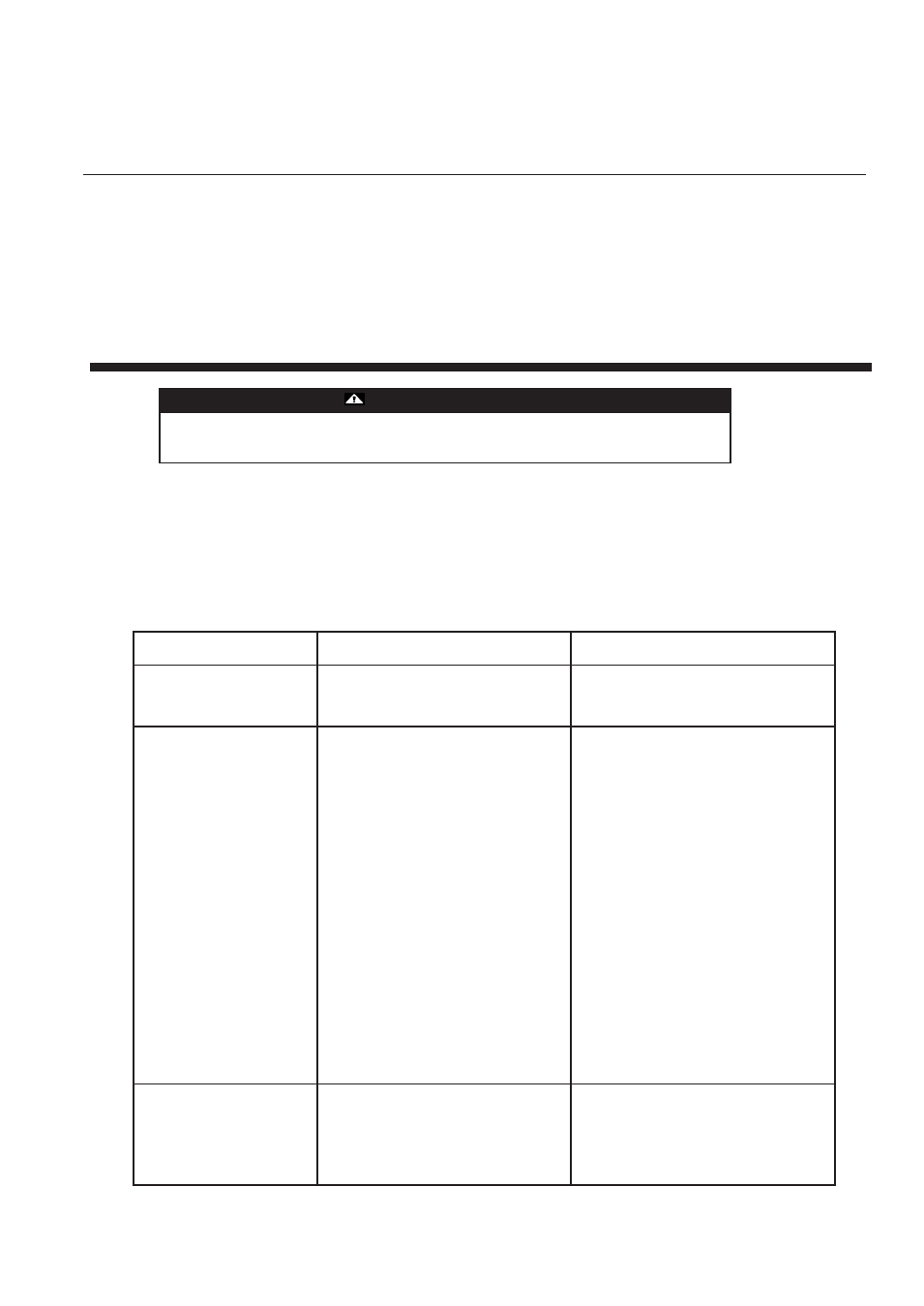

TROUBLE SHOOTING

SYMPTOM

POSSIBLE CAUSE

REMEDY

No signal

1a) No power

Check power / wiring

1b) Electronic failure

Return to factory

Controller indicates

2a) Liquid source is empty

Check in-line filters, liquid

zero flow, regardless

or blocked

supply. Shut-off valve etc.

of command

2b) Supply pressure too high

Lower supply pressure

or differential pressure too high

2c) VOR input is -15 to 0 Vdc

Determine undesirable voltage

at VOR input

2d) Valve clogged

Remove, clean and adjust orifice.

(valve voltage will increase

See 6a.

to max.)

2e) Valve seat not compatible

Choose correct valve seat

with liquid (valve voltage max.)

material (consult factory)

2f) Electronic failure

Return to factory

Output controller

3a) Pressure diff. too low/

Increase pressure diff., clean

much lower than

in-line filter contaminated,

filter/sensor/valve (6a)

setpoint

sensor/valve clogged

d. Orifice disassembly

1. Use a screwdriver to remove the orifice through the process connection from the outlet body.

2. Take care of the o-ring.

3. Apply Nitrogen gas flow at 2 bar inlet pressure.

4. Screw the orifice in the outlet body and adjust till 0% output signal has been reached again.

5. Check if value opens at 5-7 Vdc. if not, adjust orifice (final turn: clock wise).

WARNING:

Service and troubleshooting should be performed only by personnel who have

been trained in

safe repair procedures who have thoroughly read this manual.

Section 4 Maintenance