Flomega, liquid mfc’s/mfm’s – Brooks Instrument 5882/92 User Manual

Page 16

16

Installation and Operation Manual

X-TMF-FM-MFC-eng

PN 541-C-007-AAG

April, 2008

Flomega, Liquid MFC’s/MFM’s

FLOMEGA

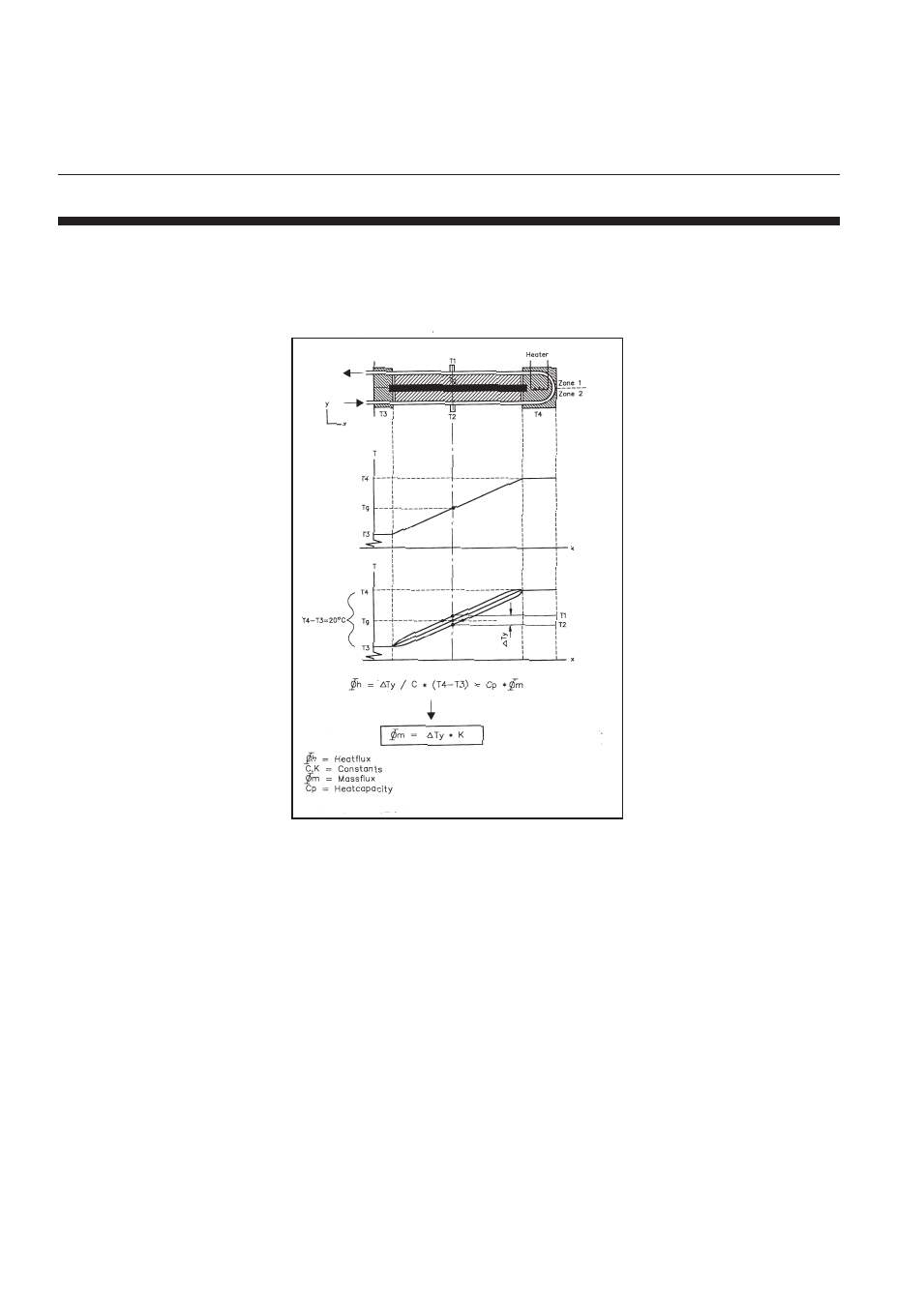

A new thermal measurement principle is used in our Flomega. The patented thru-flow sensor is especially

designed for liquids and is different from the traditional Brooks 5850 series “thermal” mass flow meters for

gases.

The by-pass or shunt technique used for gases cannot be applied for liquids; viscosity variations, air

bubbles, convection and attitude sensitivity deteriorates the performances dramatically. Therefore, Brooks

Instrument developed Flomega. This thru-flow meter is unique in its patented design, performance and

reliability.

In the new sensor, the heat transfer to and from the liquid is perpendicular to the pipe axis contrary to

classic way of heat transfer along the pipe wall. This technique enables a high heat current to and from

the liquid, which is essential for a thru-flow sensor. Using thermal feedback reduces power consumption

to a minimum.

Figure 3-1 shows the lay-out of the sensor. The temperature difference between heater and bottom of the

sensor is regulated to a constant of 10 or 20 °C. To ensure a constant heat-gradient (linearity) along the

tube, a high conductive strip (guideline) is added. A fixed conductance from the pipes to the guideline is

realized with a so-called interface material. The temperature T1 - T2 reflects the heat current to and from

the liquid. As can be seen, T1 - T2 is proportional to the liquid flow thru the sensor and the heat-gradient

at T1, T2.

Figure 3-1 Measurement Principle 5891

3-1

Theory of Operation

(refer to figures 3-1 and 3-2)

Section 3 Theory of Operation