Brooks, Model 5861 i – Brooks Instrument 5861i User Manual

Page 35

4-11

Installation and Operation Manual

X-TMF-5861i-MFC-eng

Part Number: 541B111AAG

November, 2008

Brooks

®

Model 5861

i

Section 4 Maintenance

The Model 5861

i Mass Flowmeter utilizes porous metal restrictor

assemblies for all full scale flow rates. Restrictor elements with porosities

of 40 and 60 microns are used in different combinations. Up to three

restrictor elements can be placed in one assembly. These restrictors are

assembled by pressing the porous metal elements into the header plate.

When sizing a restrictor assembly for gases other than nitrogen, the

sensor conversion factor must be used to calculate a nitrogen equivalent

flow rate. Use the following equation to obtain the desired flow in nitrogen

equivalent units. Refer to Table 4-3 for the conversion factor list.

N

2

equivalent

=

desired gas flow

sensor conversion factor

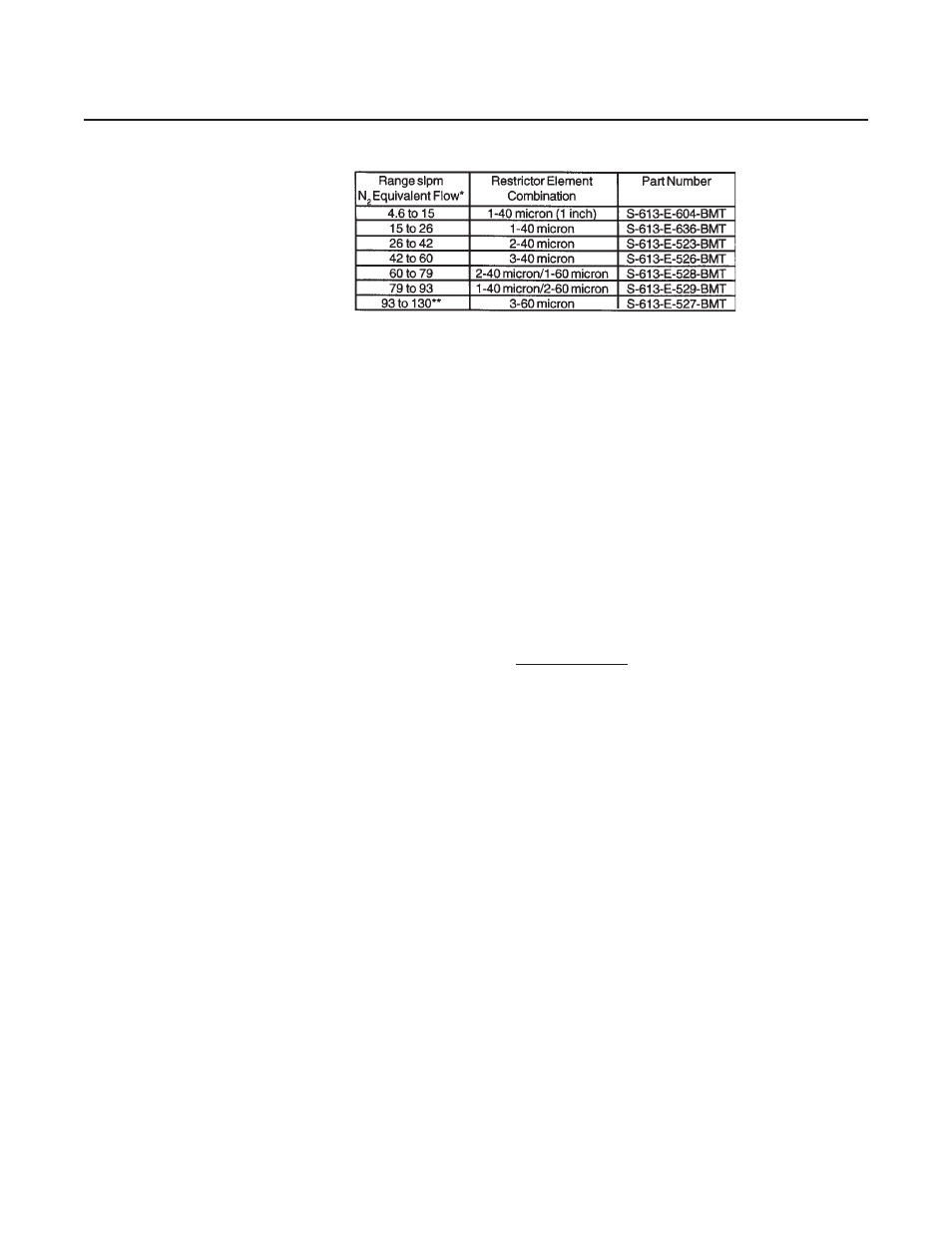

Using this Nitrogen equivalent flow, select a restrictor assembly from Table

4-4.

Example:

The desired gas is cyanogen

The desired full scale flow rate is 30 slpm.

Sensor conversion factor is 0.498 from Table 4-3.

Nitrogen equivalent flow = 30/0.498 = 60.24 slpm

In the previous example , the restrictor should be sized for a 60.24 slpm

flow rate (P/N S613E528BMT).

If a restrictor assembly is being replaced because the original has become

contaminated, the original may be used as a guide to select the

replacement assembly. The porosity of the original element or elements is

marked on the calibration sheet which was shipped with the flowmeter. The

replacement assembly should be replaced in the same orientation as the

original restrictor. (Refer to Section 4-4 for assembly procedure).

Table 4-4 Restrictor Selection Guide

Based on 0

0

C Standard Reference Temperature

**For Hydrogen from 130 slpm to 200 slpm use 3-60

micron restrictor elements.

Note: If the Nitrogen equivalent flow is between two

sizes, choose the larger size.