Brooks, Model 5861 i – Brooks Instrument 5861i User Manual

Page 19

3-3

Installation and Operation Manual

X-TMF-5861i-MFC-eng

Part Number: 541B111AAG

November, 2008

Brooks

®

Model 5861

i

Section 3 Operation

To check zero always mount the flowmeter in its final configuration and

allow a minimum of 20 minutes for the temperature of the controller and its

environment to stabilize. Using a suitable voltmeter check the flowmeter

output signal. If it differs from the factory setting adjust it by removing the

lower pot hold plug, which is located closest to the controller body. Adjust

the zero potentiometer (refer to Figure 3-3) until the desired output signal is

obtained.

3-4 Calibration Procedure

NOTE 1: This calibration procedure is shown using the voltage output (not

current). The conversion accuracy of the voltage to current convertor

allows this with no loss in accuracy using the 4-20 mA output.

NOTE 2: If the mass flowmeter is to be used on a gas other than the

calibration gas, apply the appropriate sensor conversion factor. ( Refer to

Section 4-5).

NOTE 3: Calibration of the Model 5861i mass flowmeter requiresthe use of

a Digital Voltmeter (DVM), and a flow control valve or mass flow controller

to set the flowrate and precision flow standard calibrator such as the Brok

Uol-U-Meter. It is recommended that the calibration be performed only by

trained and qualified service personnel.

a. Adjust the anticipate potentiometer fully clockwise (20 turns). Then

adjust the anticipate potentiometer 10 turns counter clockwise to

center the potentiometer. This will provide a rough adjustment of this

circuit.

b. Connect the DVM positive lead to the 0-5V signal output

(pin 2 D-connector) and the negative lead to circuit common (TP4).

Adjust the zero potentiometer for an output of 0mV ±2mV.

c. Increase the flow rate until the flow signal output equals 5.000V.

Connect the DVM positive lead to TP2 (linearity voltage) and the

negative lead to TP4 (circuit common). Adjust the linearity potenti-

ometer for an output of 0.0V (zero volts).

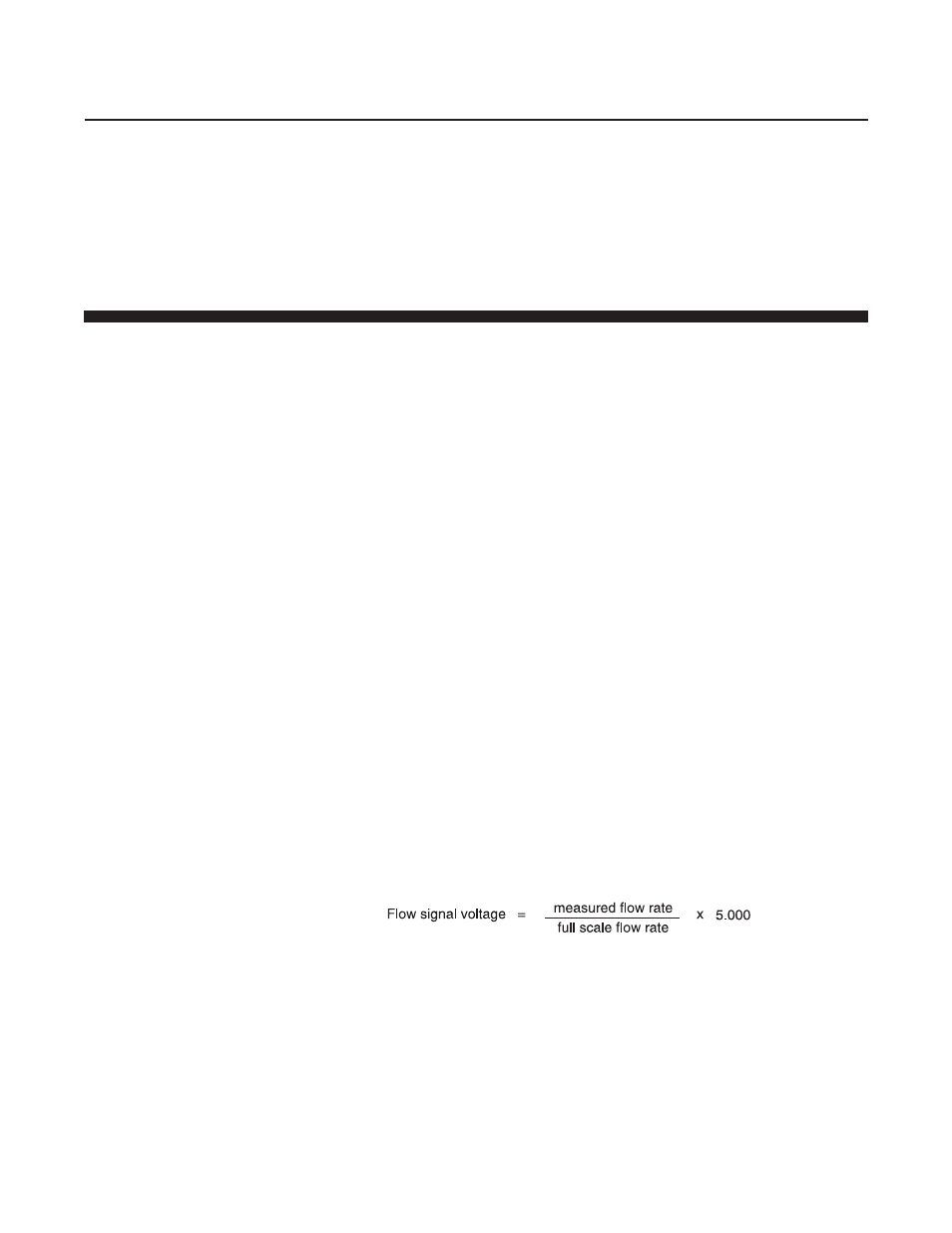

d. Connect the DVM positive lead to the 0-5V signal output (pin 2 of D-

Connector) and the negative lead to TP4 (circuit common). Adjust

the actual flow rate to within ±2% of desired full scale flow. Measure

the flow rate using suitable volumetric calibration equipmentand

record value. Calculate flow signal voltage with the following for-

mula:

Adjust the span potentiometer (Refer to Figure 3-3) until the 0-5V

signal output equals the flow signal voltage calculated above.

e. Connect the DVM positive lead to TP1 (sensor voltage). The voltage

at TP1 is -100 times the output voltage of the sensor. This voltage

can range from +1.2 to +12 volts, however it is recommended that

this voltage stay between +2.0 to +9.0 volts for proper operation. If

the recommended voltage range exceeds this than the desired

accuracy and/or signal stability may not be achieved. If one of the

limits is reached check the restrictor sizing procedure.

( Refer to Section 4-6).