Brooks, Model 5861 i – Brooks Instrument 5861i User Manual

Page 21

3-5

Installation and Operation Manual

X-TMF-5861i-MFC-eng

Part Number: 541B111AAG

November, 2008

Brooks

®

Model 5861

i

Section 3 Operation

f. Shut off the flow. Connect the DVM positive lead to flow signal output

(pin 2 D-connector) and the negative lead to TP4. Readjust the zero

potentiometer for an output of 0mV±2mV as necessary.

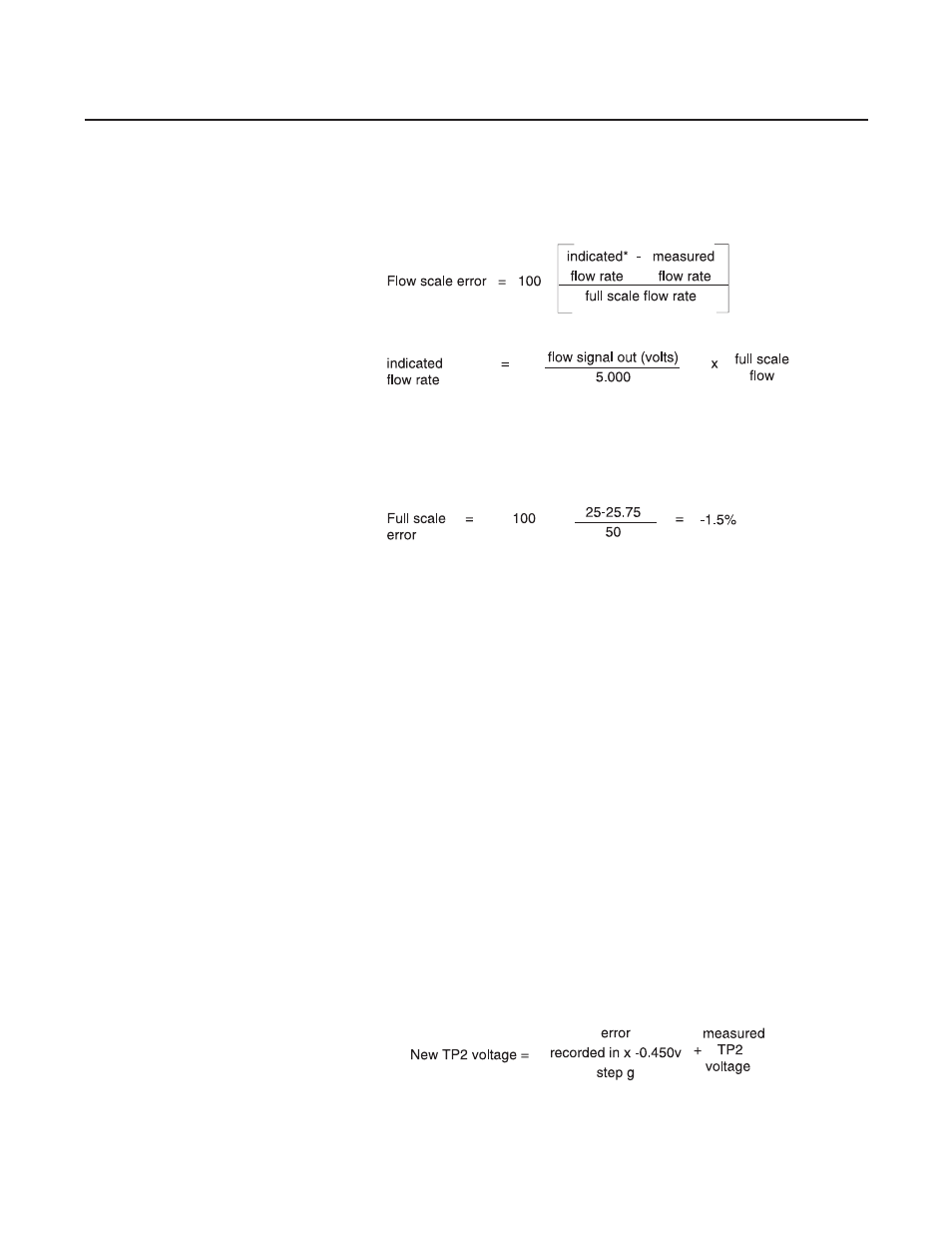

g. Adjust flow rate for a flow signal output of 50% (2.500V) and mea-

sure the flow rate. Calculate the error as a percentage of full scale.

Note: indicated flow rate can be found using the following formula:

Example:

What is the percent of full scale error when full scale is equal to 50 slpm?

Measured flow rate = 25.75 slpm

Indicated flow rate = 25 slpm

h. Calculate the TP2 correction voltage:

(error recorded in step g) x -0.450 volts

Example:

Error = -1.5%

TP2 correction voltage = -1.5 x- 0.450 = 0.675 volts

New TP2 voltage = 0 volts + (0.675) = 0.675 volts

i. Adjust flow rate for a flow signal output of 100% (5.000V). Connect

the DVM positive lead to TP2 and the negative lead to TP4.

j. Adjust the linearity potentiometer for an output equal to the new

calculated TP2 voltage.

Note: the output signal should be kept at

5.000 V during this adjustment.

This can be done by varying the actual flowrate.

k. Repeat steps d, e, f and g.

1. If the error recorded in step g is less than 0.5%, then the calibration

procedure is complete.

2. If the error is greater than 0.5% set the flow rate for a flow signal

output of 100% (5.000V). Connect the DVM positive lead to TP2

(linearity voltage) and the negative lead to TP4 (circuit common).

Calculate a new TP2 voltage as follows:

Example:

Full scale error = 0.7% (found in step g)

Measured TP2 voltage = -0.567 volts

TP2 correction = 0.7 x -0.450 = -0.315 volts

New TP2 correction = -0.315 + (-0.567) = -0.882 volts