Brooks, Model 5861 i – Brooks Instrument 5861i User Manual

Page 33

4-9

Installation and Operation Manual

X-TMF-5861i-MFC-eng

Part Number: 541B111AAG

November, 2008

Brooks

®

Model 5861

i

Section 4 Maintenance

Where,

P1 = percentage (%) of gas 1 (by volume)

P2 = percentage (%) of gas 2 (by volume)

Pn = percentage (%) of gas n (by volume)

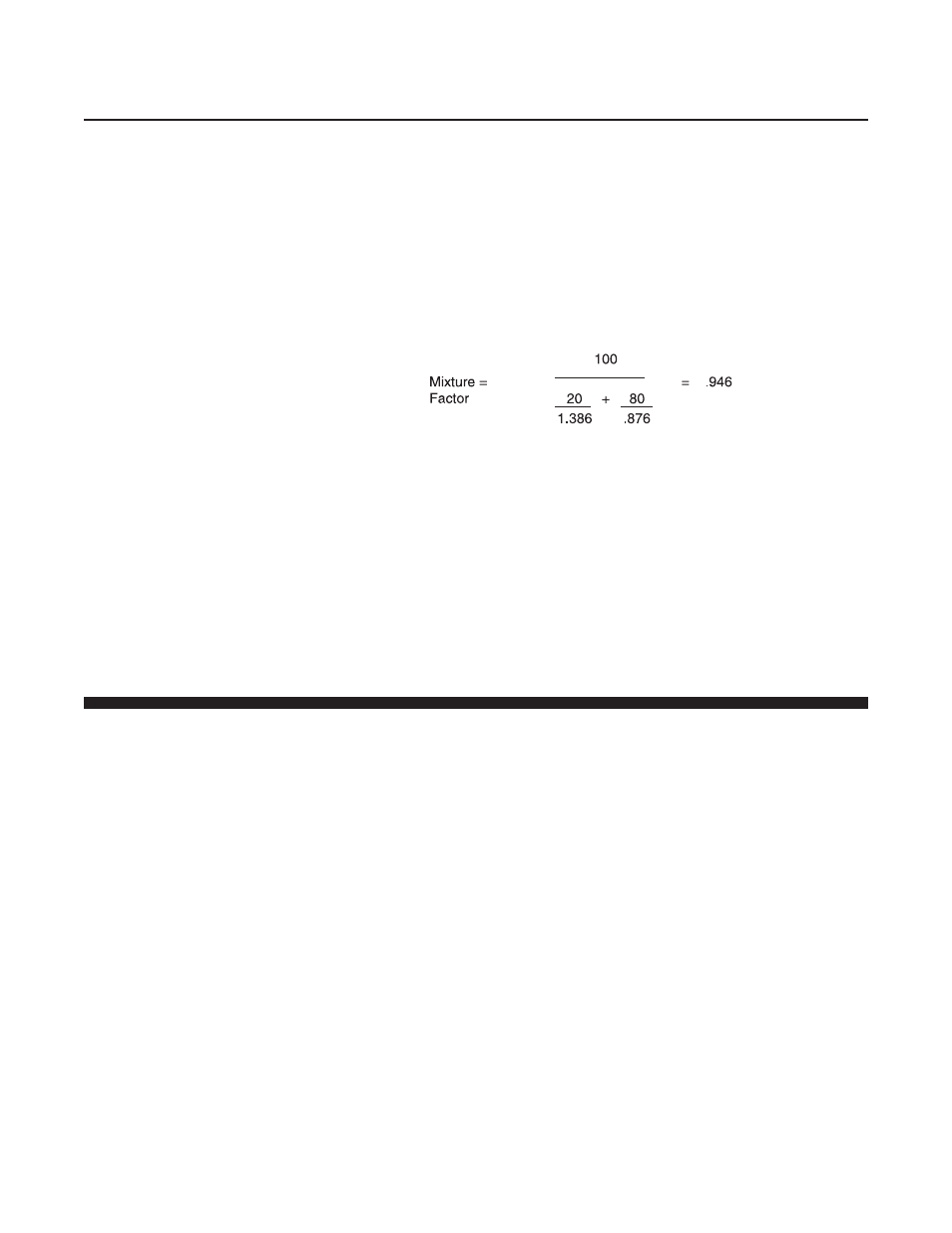

Example: The desired gas is 20% Helium (He) and 80% Chlorine

(Cl) by volume. The desired full scale flow rate of the mixture is 20

slpm.

Sensor conversion factor for the mixture is:

N

2

equivalent

flow

=

20/0.946 = 21.14

slpm

It is generally accepted that the mass flow rate derived from this equation

is only accurate to ±5%. The sensor conversion factors given in Table 4-3

are calculated based on a gas temperature of 21°C and a pressure of one

atmosphere. Gas conditions that vary widely from these reference

conditions may cause an additional error due to the change in specific heat

due to temperature and/or pressure.

4-6 Restrictor Sizing

The restrictor assembly is a ranging device for the flow sensor. It creates a

pressure drop which is linear with flow rate. This diverts a sample quantity

of the process gas flow through the sensor. Each restrictor maintains the

ratio of sensor flow to restrictor flow, however the total flow through each

restrictor is different. Different restrictors (micron porosity and active area)

have different pressure drops and produce meters with different full scale

flow rates. For a discussion of the interaction of the various parts of the

meter, you are urged to review Section 3-1 (Theory of Operation).

If the restrictor assembly has been contaminated with foreign matter, the

pressure drop vs. flow characteristics will be altered and it must be cleaned

or replaced. It may also be necessary to replace the restrictor assembly

when the mass flowmeter is to be calibrated to a new flow rate.

Restrictor assembly replacement should be performed only by trained

personnel. The tools required for the removal/replacement procedure are

as follows:

-

Appropriate size wrench for the removal of the inlet process connection

and end block screws.

-

Restrictor removal tool (Refer to Table 5-2)

-

Restrictor O-ring, refer to the spare parts Section 5, for the correct part

number.