BEI Sensors Programmable Hall Device User Manual

Page 9

7230 Hollister Avenue, Goleta, California 93117 | Tel: 805-968-0782 | Fax: 805-968-3154 |

www.beisensors.com

9

Specification No.: 02135 Rev: 5-23-2013

PHD User Manual

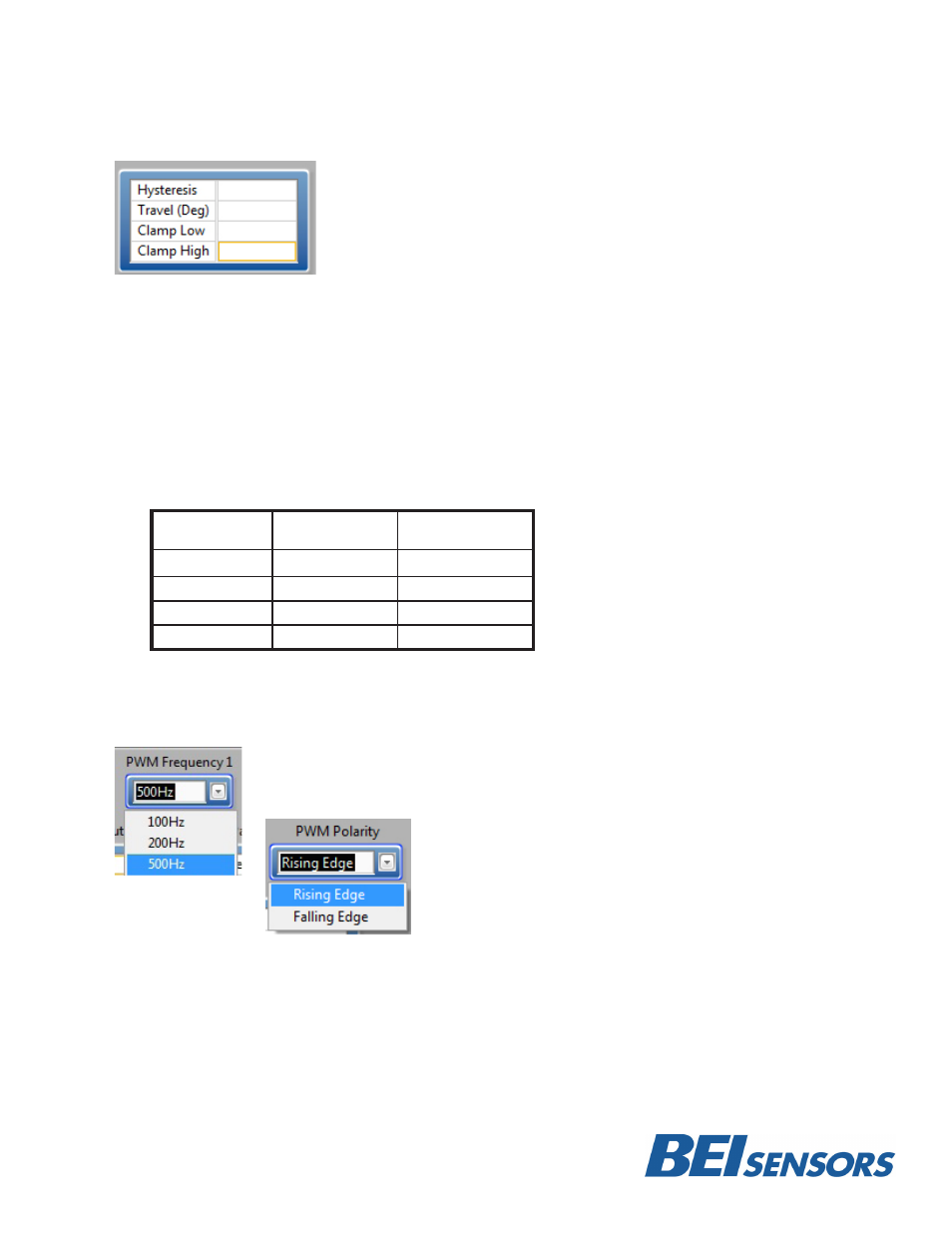

7. Define four additional parameters for the part:

•

Hysteresis– The Hysteresis option allows you to to

independently program the amount of hysteresis each output

will have. A value of zero degrees will give the minimum amount

of hysteresis and 11 degrees will give the maximum amount of

hysteresis. This value is most commonly set to zero.

•

Travel (Deg)– The Travel option allows you to program the

rotational angle you want to resolve. Values from 1° to 360° are

valid, however the linearity of the output may be negatively impacted for angles less than

15°. It is possible to program a separate angle for each of the sensor’s outputs; however

a slightly different programming sequence from this example is required.

•

Clamp Low and Clamp High– Allows you to independently set min/max percentage

limits for each output. These limits restrict each output from going beyond the limit

programmed. Clamp High and Low work exactly the same way for the Non-Ratio Metric

and PWM units as it does for the Ratiometric. For example assuming 5VDC is supplied to

the sensor’s input, the output would be as follows:

Clamp Low

(%)

Clamp High

(%)

Min/Max Vout

(V)

0

100

0/5

5

95

0.25/4.75

10

90

0.5/4.5

25

80

1.25/4

8. If PWM was selected as the Output Type two additional parameters must be set:

•

PWM Frequency is the output frequency which the PWM unit will output

at, this value is CONSTANT and does not change with output location.

•

PWM Polarity determines how the Duty Cycle

changes based on the position of the shaft.

•

Rising Edge– 0% High at 0% position, 100% High at

100% position.

•

Falling Edge– 0% High at 0% position, 100% High at

100% position.