Hip & ridge detail headwall detail valley detail – ATAS Field-Lok User Manual

Page 3

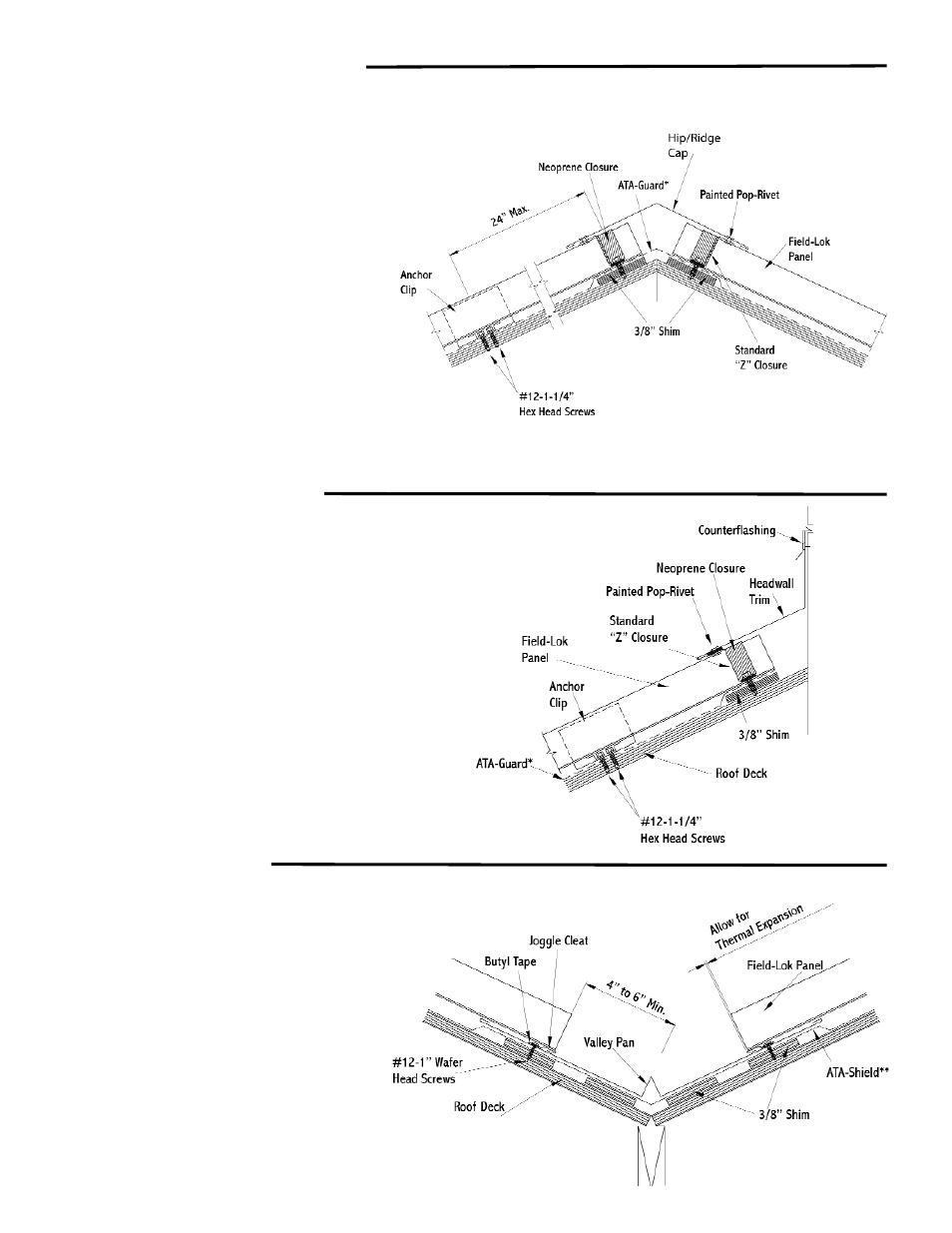

Hip & Ridge Detail

Headwall Detail

Valley Detail

Hip and ridge applications are handled

in the same manner.

1. Install underlayment to roof edge.

Place 3/8” shim as shown.

2. Cut “Z” closure to fit between seams and install in

butyl tape. Fasten through 3/8” shim to secure

panel (Use 4 fasteners on 13 3/4”, 5 on 18” )

3. Seal neoprene strips into “Z” closures .

4. Snap hip/ridge cap over “Z” closures for it to lock

into place. Pop-rivet one side only to allow for

expansion and contraction.

Notes:

* Trim must be pop-riveted to Z in at least one

location to control thermal movement.

* Unless otherwise specified, all fasteners for trim

components should be spaced at 2’-0” o.c.

* Install splice plates at ridge cap joints. Pop rivet

splice to one end of ridge cap to allow for

expansion and contraction.

.

1. Install underlayment to roof edge.

Place 3/8” shim as shown.

2. In standard headwall situation (without venting),

run underlayment from roof plane up headwall.

Install panels up to headwall.

3. Fasten “Z” closure in bed of sealant at top of

panel. Fasten through 3/8” shim to secure panel.

(Use 4 fasteners on 13 3/4”, 5 on 18” )

4.Seal neoprene closure into “Z” closure.

5. Install headwall transition over “Z” closure.

6. Apply counterflashing over the headwall trim,

as required.

1. Install ATA-Shield** approximately 18” up

both sides of the valley line.

2. Place 3/8” shim as shown.

3. Lay valley pan in valley center. Locate joggle

cleat at 4” to 6” from valley center.

4. Install joggle cleat. Fasten 6” o.c. through

butyl tape and pan into 3/8” shim and substrate.

5. Turn under edge of panel to slide into

joggle cleat. Fasten with clips at 2’-0” o.c.