ATAS Flat Sheet and Coil Stock User Manual

Atas international, inc, Specification data sheet, Flat sheet and coil

ATAS INTERNATIONAL, INC.

6612 SNOWDRIFT ROAD ALLENTOWN, PENNSYLVANIA 18106

PHONE (610) 395-8445 FAX (610) 395-9342

SPECIFICATION DATA SHEET

FLAT SHEET AND COIL

1. PRODUCT DESCRIPTION

Aluminum or Metallic Steel with PVDF finish used to produce flat

sheets and coils.

Aluminum Alloy ASTM B 209 Alloy 3003 H14 or 3105 H14, or

Metallic Coated Steel ASTM A 653 Structural Steel SS 50 (SS 37

for 48” width) with G90 coating or ASTM A 792 structural steel

grade 50 (grade 37 for 48” width) with AZ50 coating. Materials

are pretreated, primed and coated with a full strength PVDF

(containing a minimum of 70% KYNAR 500

®

or HYLAR 5000

®

Resin) coating system, consisting of nominal 1.0 mil total dry film

thickness (.2 mil primer with a .8 mil top coat). Reverse side is

coated with a wash coat of .4 to .5 mil dry film thickness.

Galvanized materials are pretreated with a high-performance zinc

phosphate system.

Masking, a strippable polymer film, can be applied as a protective

covering for handling during fabrication and installation of

materials, if requested. The polymer masking must be removed

immediately after installation and should not be exposed to

continued periods of direct sunlight or extreme heat.

Basic Use: Architectural Sheet Metal applications in general

building construction, such as metal roofing, mansard applications,

fascias, soffits, ceilings, storefronts, copings, gravel stops, specialty

accent details, etc.

Materials:

Gauges Available:

Aluminum - .032, .040, .050, .063 and .080 thicknesses.

Metallic Coated Steel - 22, 24 and 29 gauge.

Sheet Sizes - Up to 60" width by length required.

Texture - Smooth and stucco embossed available.

Limitations:

All ATAS materials are pre-finished and, therefore, care should be

taken during fabrication and installation of materials. Fabrication

and installation of materials should conform to standards

established by the Architectural Sheet Metal Community. During

the fabrication and/or forming of the materials, proper bend radii

must be used. Minor scratches should be touched-up immediately,

utilizing an air dry coating furnished by ATAS. For damage other

than minor scratches, such as dents, deep abrasions, or scratches

which have damaged base materials, the actual unit should be

replaced. All metal shavings, chips, and dust must be removed

from material immediately.

2. TECHNICAL DATA

Applicable Standards

Aluminum

Aluminum materials conform to ASTM B 209, alloy 3003 H14 or

3105 H14. Painted aluminum conforms to performance

requirements of AAMA 2605.

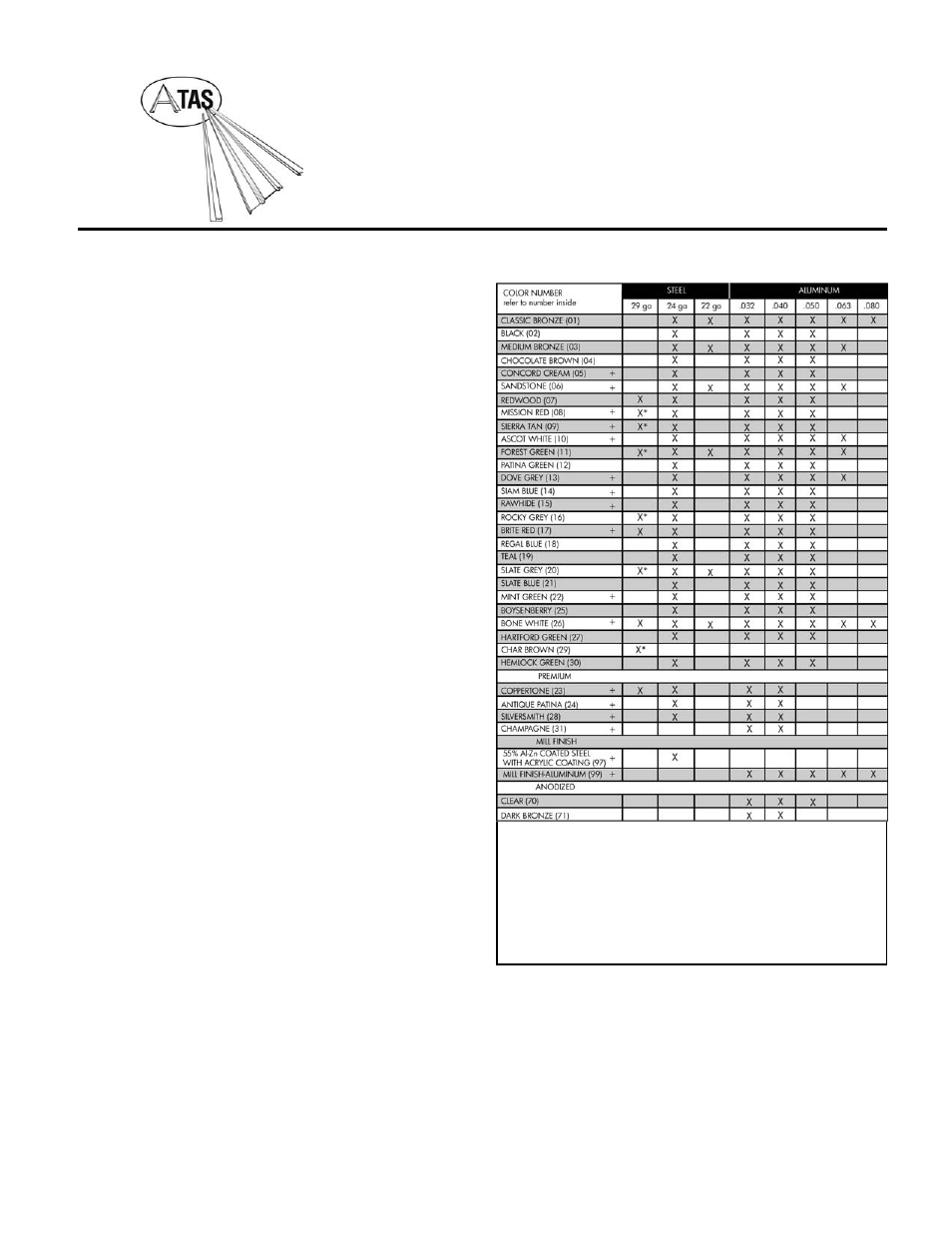

FINISH: KYNAR 500® PVDF or HYLAR 5000® PVDF

X-AVAILABLE FOR IMMEDIATE SHIPMENT * - Low GLoss Finish

+ - Meets the Requirements of ENERGY STAR® Initial Reflectance for roofing products

Visit ATAS’s Website for speciality trend colors in gauges and widths

not shown on this chart.

NOTE:

.063/.080/29 ga./22 ga. Other standard colors may be available,

subject to minimum quantity, coating surcharge and longer lead time

KYNAR 500

®

is a registered trademark of Arkema.

HYLAR 5000

®

is a registered trademark of Ausimont.

Metallic Coated Steel

Both Galvanized Steel and 55% Al-Zn coated Steel meet general

requirements of the construction industry. Galvanized Steel

materials conform to ASTM A 653, with a G90 coating. 55% Al-Zn

coated Steel materials conform to ASTM A 792, with an AZ50

coating. Materials are structural steel grade 50 except for 29 ga.

thickness and 48 inch wide sheets, which are grade 37.