ATAS Multi-Purpose Panel User Manual

Atas international, inc, Specification data sheet, Multi-purpose panel

ATAS INTERNATIONAL, INC.

SPECIFICATION DATA SHEET

1. PRODUCT NAME

MULTI-PURPOSE PANEL™

2. MANUFACTURER

ATAS INTERNATIONAL, INC.

Website: www.atas.com

Email: [email protected]

Corporate Headquarters:

Allentown, PA 18106

Phone: (610) 395-8445

Fax: (610) 395-9342

Western Facility:

Mesa, AZ 85204

Phone: (480) 558-7210

Fax: (480) 558-7217

Southern Facility:

Maryville, TN 37801

Phone: (800) 468-1441

3. PRODUCT DESCRIPTION

Basic Uses:

Multi-Purpose panels with the Wind-Lok

application have a smooth, sleek appearance

with a concealed, clipless fastening system.

These panels are typically used for siding,

fascias, mansards and equipment screens.

Composition & Materials:

Standard Offerings: Panels are roll-formed from

.032 or .040 Aluminum or 24 gauge Metallic

Coated Steel. Special Offerings: 22 gauge

Metallic Coated Steel.

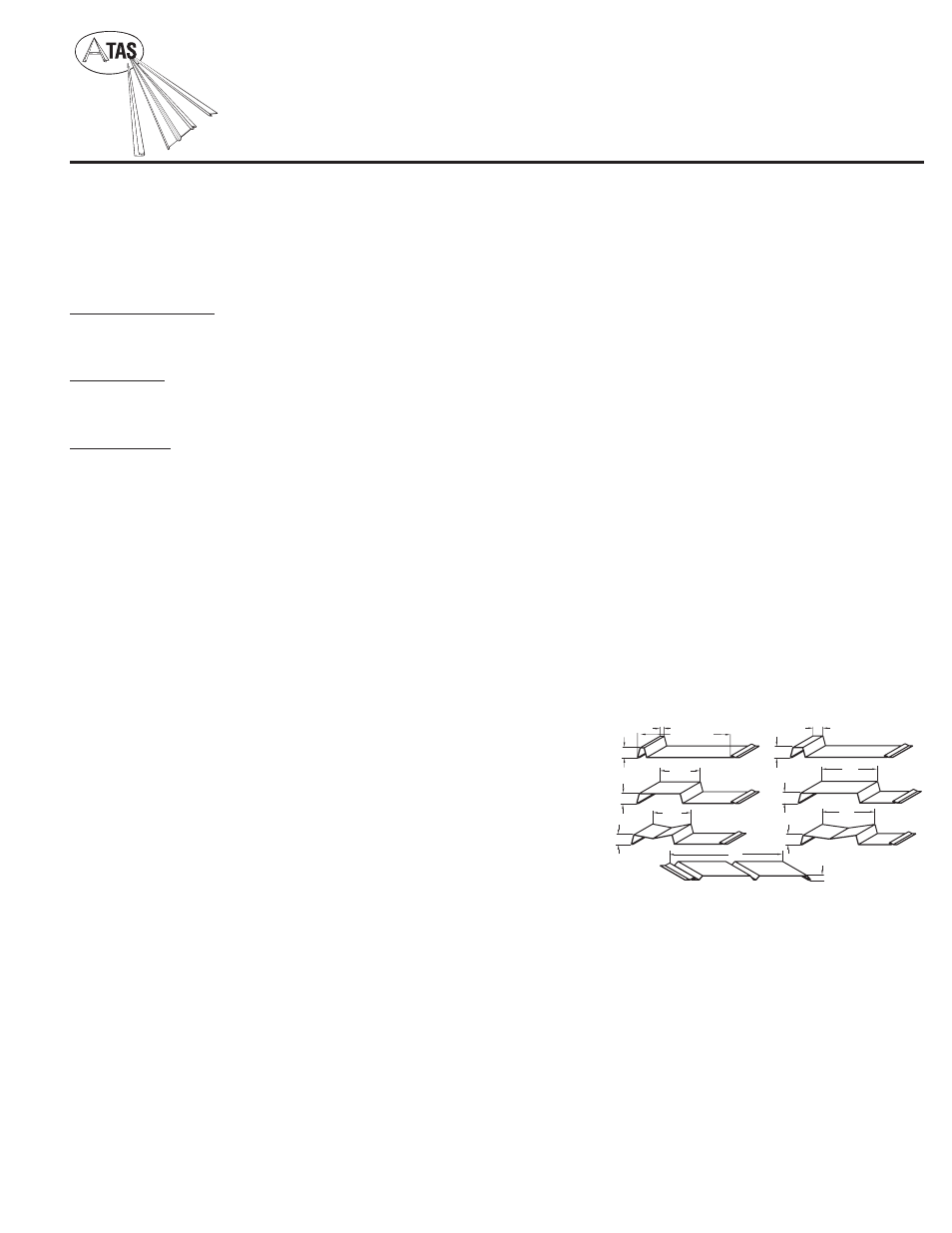

Sizes and Profiles:

Four 8” wide panels, seven 12” wide panels and

six 16” wide panels are available. The semi-

standing seam (MPN code), the batten style

(MPW code) and the plank or barn board (MPH

code) give completely different appearances.

A slight “V” in the MPH series gives another

variation in style (MPV code). Panel lengths

are cut to customer specifications.

Colors & Finishes:

A choice of 30 colors is available in a KYNAR

500® PVDF or HYLAR 5000® PVDF finish.

(Request color chart or chips). An anodized

finish is available in Clear or Dark Bronze.

Texture may be smooth or stucco embossed.

4. TECHNICAL DATA

KYNAR 500® PVDF or HYLAR 5000® PVDF based

finishes tested by paint supplier for:

Dry Film Thickness: ASTM D 1005, ASTM D

1400, ASTM D 4138 or ASTM D 5796

Specular Gloss: ASTM D 523

Pencil Hardness: ASTM D 3363

T-Bend Flexibility: ASTM D 4145

Mandrel Bend Flexibility: ASTM D 522

Impact Resistance: ASTM D 2794

Adhesion: ASTM D 3359 Water Immersion

Resistance: ASTM D 870

Abrasion Resistance: ASTM D 968

Acid Resistance: ASTM D 1308

Acid Rain Resistance (Kesternich):

ASTM G 87 or DIN 50018

Salt Spray: ASTM B 117

Cyclic Salt Spray: ASTM D 5894 and ASTM D

5487

Humidity Resistance: ASTM D 2247

Accelerated Weathering: ASTM D 822 and

ASTM G 23, ASTM G 151 or ASTM G 153

Color Retention, Florida Exposure:

ASTM D 2244

Chalking Resistance – ASTM D 4214

Cleveland Condensing Cabinet: ASTM D 4585

Cure Test, MEK Resistance: ASTM D 5402

Alkali Resistance, Sodium Hydroxide: ASTM D

1308, Procedure 7.2

Flame Spread Rating: ASTM E 84

Organic coatings meet requirements of AAMA

2605 when applied to aluminum.

Panel testing/ratings:

UL 580 Class 90 (UL File No. R121123)

Air Infiltration: ASTM E 283

Water Penetration: ASTM E 331

Wind Driven Rain: AAMA 501.1

Fire Resistance: UL 790/ASTM E 108

Class A & B Fire Rating

Galvanized Steel: ASTM A 653

Aluminum: ASTM B 209

Coil Coating: ASTM A 755

Field Tested and Approved

Load Tables available upon request.

5. INSTALLATION

Installation is achieved by interlocking the

panel into the preceding panel and

fastening with mechanical fasteners.

The rib of the adjoining panel will conceal

the fasteners. Installation manuals or

hands-on training via seminars are available

through ATAS. Visit www.atas.com for more

information.

6. AVAILABILITY & COST

Availability:

Multi-Purpose panels are available through

ATAS product distributors. A complete line of

related components and trim accessories is

available to complete the roof or wall system.

In addition, a complete line of rainware and

perimeter roof edge trims can be supplied

by ATAS to complement the wall system. Flat

sheet and/or coil stock is available in matching

color for fabrication of related components by

the installing contractor.

Cost :

Contact ATAS product distributors for current

pricing.

7. WARRANTY

Products coated with a fluoropolymer, KYNAR

500® PVDF or HYLAR 5000® PVDF finish carry

a thirty (30) year limited warranty against

chipping, cracking, peeling, chalking and

fading.

8. MAINTENANCE

Multi-Purpose panels are virtually

maintenance free. Surface residue may be

easily removed by conventional cleaning

methods. Minor scratches may be touched

up with a matching paint, available from the

manufacturer.

9. TECHNICAL SERVICES

Complete technical information and literature

are available at www.atas.com. ATAS will assist

with design ideas and shop drawings.

10. FILING SYSTEM

• www.construction.com

• www.atas.com

• Additional product information is available

from the manufacturer upon request.

Multi-Purpose Panles

TM

are trademarks of ATAS International, Inc.

KYNAR 500

®

is a registered trademark of Arkema.

HYLAR 5000

®

is a registered trademark of Solvay Solexis, Inc.

© 2009 ATAS International, Inc.

DIH0709 LAT751

1 ¼"

1 ¼"

7 ¼”

8”, 12”, 16”

½”

MPN

MPW

MPH

MPV

MPS

1 ¼"

1 ¼"

1 ¼"

1 ¼"

1 ¼"

5 ¼"

5 ¼"

7 ¼”

�⁄�"

12"