ATAS InSpire SOLAR COLLECTOR BWS390, BWS392 User Manual

Atas international, inc, Specification data sheet, Inspire

ATAS INTERNATIONAL, INC.

SPECIFICATION DATA SHEET

1. PRODUCT NAME

InSpire

TM

SOLAR COLLECTOR

BWS390, BWS392

2. MANUFACTURER

ATAS INTERNATIONAL, INC.

Website: www.atas.com

Email: [email protected]

Corporate Headquarters:

Allentown, PA 18106

Phone: (610) 395-8445

Fax: (610) 395-9342

Western Facility:

Mesa, AZ 85204

Phone: (480) 558-7210

Fax: (480) 558-7217

Southern Facility:

Maryville, TN 37801

Phone: (800) 468-1441

3. PRODUCT DESCRIPTION

Basic Uses:

The InSpire solar collector is a metal

wall system used to collect and distribute

solar-heated, outside air for ventilation or

processes, such as drying. The concept

is simple:

Composition and Materials:

InSpire cladding is available in .032” aluminum

and .027” pre-weathered zinc.

Sizes and Profiles:

InSpire cladding incorporates 1 1/4” high ribs.

Aluminum panels are 41 1/4” wide with 39 3/8”

coverage, and zinc panels are

33 3/8” wide with 31 1/2” coverage.

The panels can be specified in two

orientations as illustrated. Panel lengths

are cut to customer specifications up to 40’

maximum. Profiles contain proprietary lanced

perforations for air intake.

The airflow rate through each square foot of

collector panel is tailored to meet specific

project objectives:

· 1 to 3 cfm/ sq ft for high temperature gain

· 3 to 6 cfm/ sq ft for standard operation

· 6 to 10 cfm/ sq ft for high efficiency

Color and Finish:

A choice of 30 stock colors is available in

KYNAR 500® PVDF or HYLAR® 5000 PVDF

based finishes for collector panels and accent

components. (Request color chart or chips).

Four darker colors, which absorb solar energy

more efficiently, are recommended for

collector panels. A Dark Bronze anodized finish

is also available. Zinc panels have a dark, pre-

weathered finish.

Limitation:

InSpire solar collector panels heat fresh air

during the day time and are not designed

to replace conventional space heating

system. InSpire must be installed over non-

combustible wall material. Consult fire codes

for use in multi-story applications.

4. TECHNICAL DATA

Applicable Standards

Solar Collector System

The technology for perforated solar air

heating systems was developed through

extensive testing at The National Renewable

Energy Laboratory of the U.S. Department of

Energy,

and in Canada at the CANMET Energy

Diversification Research Laboratory, an agency

of Natural Resources Canada. Detailed project

performance monitoring has been conducted

under the auspices of CANMET to validate

computer feasibility software.

Collector Cladding

KYNAR 500® PVDF or HYLAR® 5000 PVDF

based

finishes tested by paint supplier for:

Dry Film Thickness: ASTM D 1005,

ASTM D 1400, ASTM D 4138 or ASTM D 5796

Specular Gloss: ASTM D 523

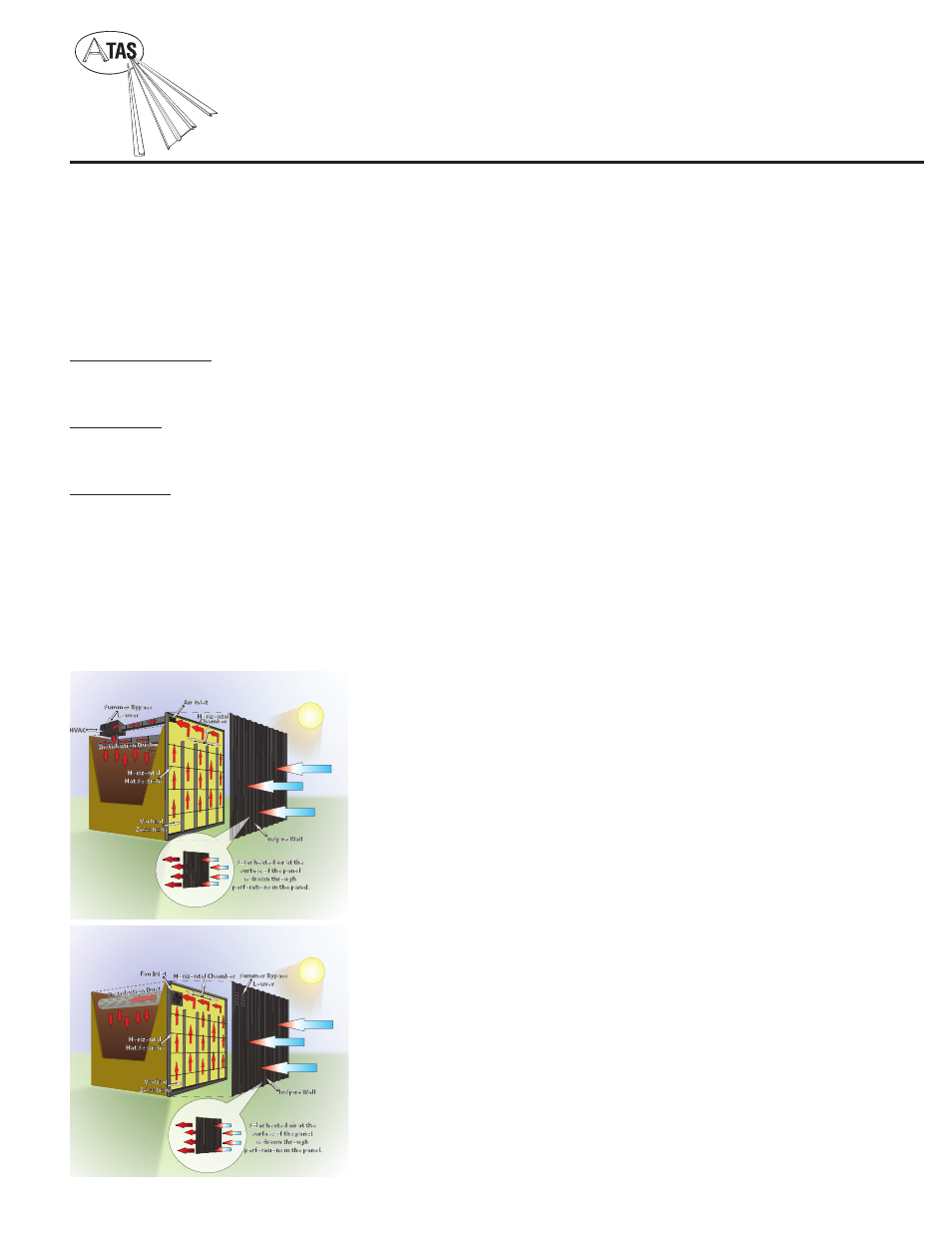

Integrated with HVAC

Stand Alone Destratification

· Perforated collector panels are installed

several inches from an appropriate wall,

creating an air cavity.

· Sunlight heats the solar collector surface.

· Fans create a negative pressure and draw

warmed air through the perforations

into the plenum.

· Heated air is distributed into the building

through the existing HVAC system or separate,

perforated ducts. The wall system should be

considered whenever outside air is being

heated. Energy savings depend on several

project-specific factors and can be predicted

by computer modeling. Factors that influence

system effectiveness include the ventilation

requirement of building, length of heating

season, utility rates for heating and the

available wall area facing south, southeast or

southwest.

There are six ways to save energy:

· Solar energy is captured by the collector.

· When the fan is running, building heat loss

through the main wall is recaptured

in the plenum.

· The air space creates an insulating effect on

the building inner wall.

· In industrial buildings, solar heated air

distributed through perforated ducts

destratifies and utilizes hot air trapped

at the ceiling.

· With lower ceiling temperatures in industrial

buildings, less energy is lost through ceiling

exhaust systems.

· Solar collector panels shield the inner wall

from direct sunlight during the summer season.

Typically, each square foot of solar collector

contributes 1.0 to 2.0 therms of energy per

year. Annual heating costs are usually reduced

by $1.50 to $5.50 per square foot of collector,

depending on the type of fuel replaced.

Ideal applications include:

· Industrial buildings

· Hospitals and other institutional buildings

· Schools and gymnasiums

· Arenas

· Laboratories

· Maintenance facilities

· Government and military buildings

· Warehouses

· Theaters and conference centers

· Restaurants

· Other commercial buildings

Major system components may include:

· Wall panels

· Standoffs and canopy components

· Fans, controls, dampers and ducting

· Trim and closures