ATAS Field-Lok Low Slope User Manual

Low slope, Installation guide

Installation Guide

Review and under-

stand complete

guide before begin-

ning installation.

This guide has been prepared as suggested details to

particular design conditions. Each condition has certain

limitations to performance, aethetics or economics.

Professionals qualified to assess this information for a

specific project, should determine that the selection and

installation are made to their requirements. ATAS cannot

assume any responsibility for the actual selection and/or

installation of materials. The panels, flashings and trim

shown in this guide are illustrated over solid and plumb

substrate. It is assumed that the structure has been

designed and prepared in accordance with local building

codes.

NOTE : This guide to be used for installations with

a roof slope of 2:12 or less only on a solid sub-

strate. Consult factory for all other installations.

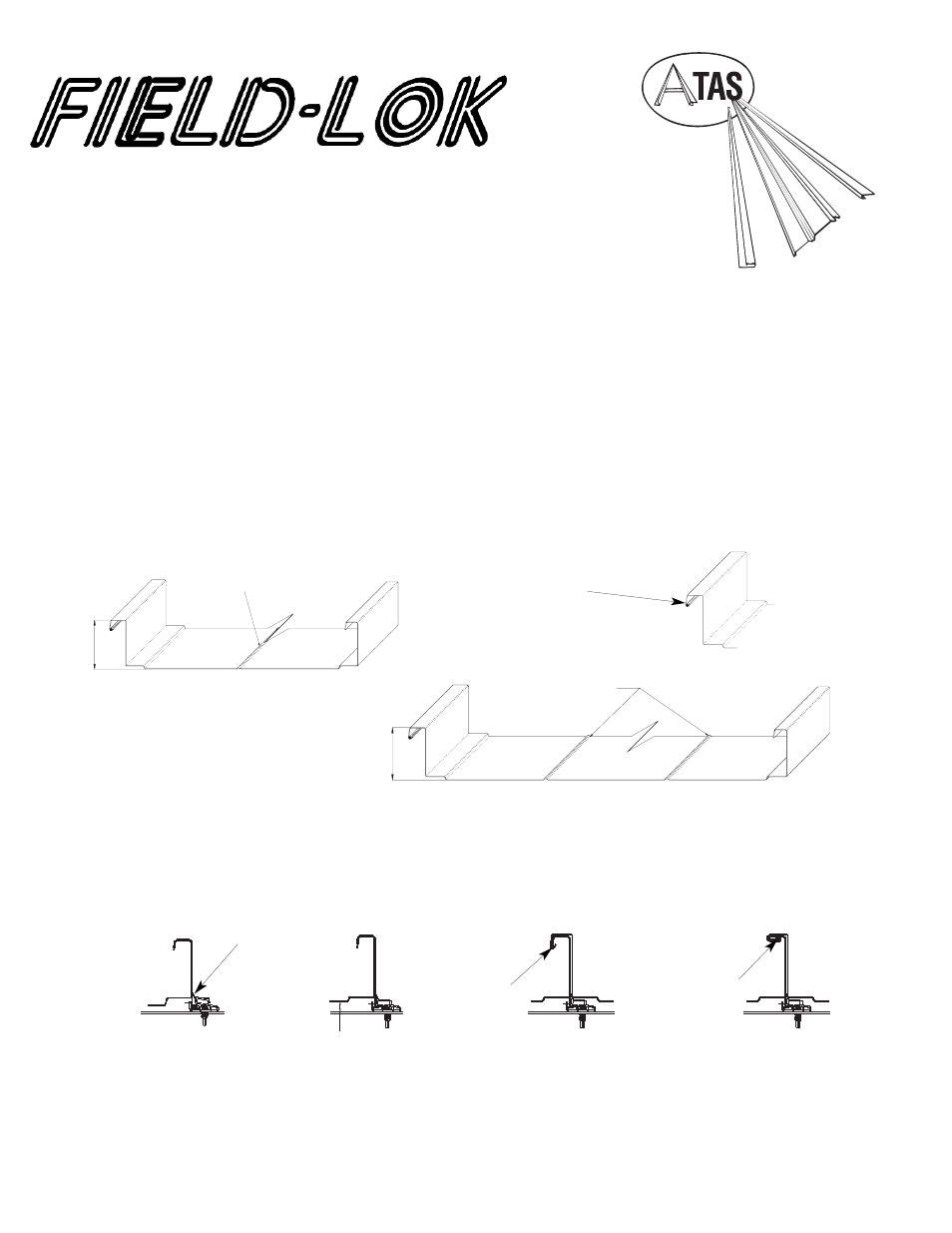

Field Lock Panel has extra strength, extra height - field

seamed panel. Installed with concealed clips and fasteners

and a mechanical seamer in a tri-fold lock-in application.

Panels are available in smooth or embossed texture in 29

standard ATAS colors are available with premium KYNAR

500® or HYLAR 5000® finish. Stiffening ribs are optional.

Low Slope

Field-Lok Seam Panel Anchoring

Note: The appro-

priate fasteners

must be sufficiently

long enough to

penetrate through

a solid substrate.

Step #1 - Locate the anchor

clip over the right (male) leg of

the previously laid panel to

afford the proper clip spacing -

note how the base centering

stops positions and holds the

movable section of the clip.

DO NOT fully set the screw(s)

until all have been located

along this seam line.

Step #2 - Fully set the screw(s)

and note how this action now

releases the movable section of

the clip and allows for roof

movement (expansion /

contraction).

Step #3 - Hook the entire left

(female) leg of the next panel

over the right (male) leg of

the previously installed panel

making sure to fully engage

the factory installed sealant

(optional).

Step #4 - Roll seam the joint

utilizing the joint seamer.

3/8”

Base center-

ing stops

Factory

applied

sealant

(optional)

Factory

applied

sealant

(optional)

"PENCIL GROOVE" TYPE

STIFFENING RIBS

2 3/8"

( OPTIONAL )

13 3/4” (FLS137) and 18” (FLS180) wide

FLS Panel

FLS180

"PENCIL GROOVE" TYPE

STIFFENING RIB

2 3/8"

( OPTIONAL )

FLS137

Factory Sealant

(optional)