About the ipcp pro series, Features, About the ipcp pro – Extron Electronics IPCP Pro Series User Guide User Manual

Page 8: Preliminary

IPCP Pro Series • Introduction

2

About the IPCP Pro Series

The IPCP Pro Series Control Processors integrate Ethernet connection into AV systems to

allow users to remotely control, monitor, and troubleshoot AV equipment, including display

devices and switchers, source devices, and various other items such as lights, a projector

lift, or a screen motor. They can be used in a distributed control system environment or as

stand-alone control processors. Some models also have the ability to power devices that

accept 12 VDC.

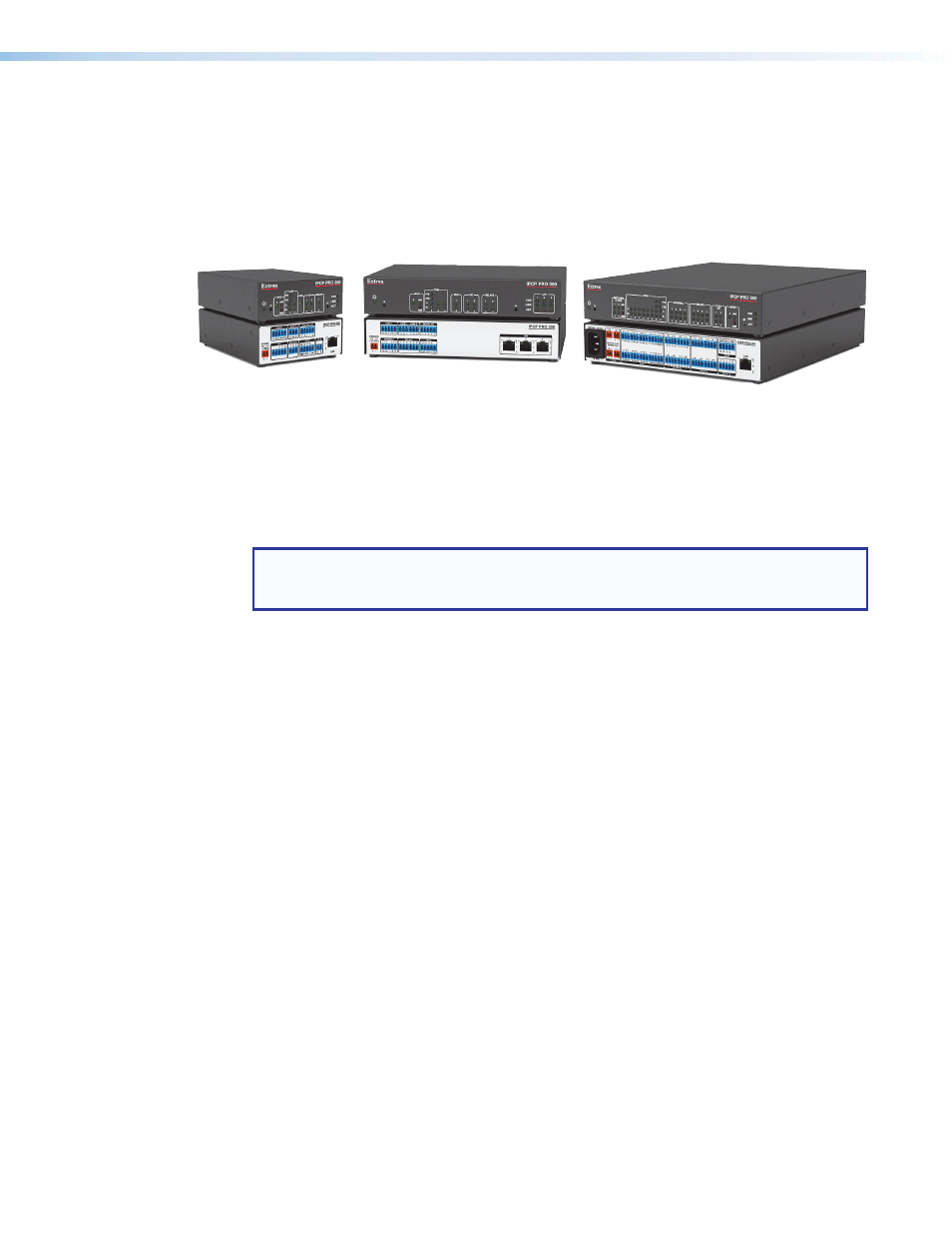

Figure 1.

IPCP Pro 250 (left), IPCP Pro 350 (center), IPCP Pro 550 (right)

An IPCP Pro Series control processor acts as the centerpiece of a control system that

features Extron TouchLink Pro Touchpanels. The IPCP supports multiple TouchLink Pro

touchpanels over a standard Ethernet network. The touchpanels provide a convenient,

aesthetically pleasing interface for controlling the IPCP, which, in turn, controls the other

system components. Another option is to use a third party device such as a touchpanel or

tablet in conjunction with Extron LinkLicense.

NOTE: GUI Designer is used to design the user interface layout any Extron

TouchLink Pro touchpanel or third party touch interface that will be used with the

IPCP.

The IPCP is configured completely via Global Configurator software. Once you have

set up how you want it to work (set up IP addresses and functions, assigned drivers to

ports, configured relays and digital input or output), that information is saved to a project

configuration file that is built and uploaded into the IPCP and to any optional TouchLink

touchpanels.

The IPCP Pro Series integrates seamlessly with Extron GlobalViewer Enterprise (GVE)

software and the GlobalViewer web-based AV resource management tool for remote control

applications.

Features

General features

Flexible options for device control — The IPCP offers RS-232 and infrared (IR) control,

TCP/Ethernet control and monitoring, relays, and either digital I/O (digital input or digital

output) or flexible I/O (analog input or digital input or digital output) controls. Some models

also offer independently switched 12 VDC power output or a port for volume control of an

Extron audio amplifier.

Rack mountability — All models except the IPCP Pro 350M are housed in a standard 1U

high enclosure which is easily rack mounted or can be installed in or under furniture with an

optional mounting kit.

Universal power system compatibility

•

The IPCP Pro 550 includes an internal power supply that accepts 100-240 VAC,

50-60 Hz input.

•

Other models include a 12 VDC external power supply that accepts 100-240 VAC,

50-60 Hz input.

Save this text for when the eBUS ports are supported.

or Extron eBUS button panels

connected to the eBUS port on

the control processor.

A control processor can learn IR signals from remote controls

to communicate with sources such as DVD players. Users can

create their own device drivers (IR) or go to the Extron website

(

eBUS material will be reserved for later releases, once the eBUS features are implemented.

All models include Extron eBUS ports, which allow a variety of control accessories (known

as “endpoints”) to be connected to a single control processor. eBUS accessories include

an array of button panels, and contact input and relay devices. Endpoints are automatically

recognized by the control processor and can be added or removed at any time.

PRELIMINARY