6 process variable monitoring, 7 alarms/events – Xylem 10 001 262R5 AquaForce Pump Controller User Manual

Page 44

AQUAFORCE Installation, Operation, and Maintenance

38

Operation

5.6 Process Variable Monitoring

To view the actual process variable signals that are being sent to the controller press the

PV/1 key.

The following will be displayed:

ACT = ###

SP1 = ###

HZ = ##

The # symbol will be replaced by the actual value of process variables and set points.

5.7 Alarms/Events

When the controller detects an alarm/event condition, the display will flash *ALARM/EVENT* in the lower

right corner of the main screen.

The green LED on the

HELP key will also flash during an alarm/event condition. Press the HELP key for

additional information on the alarm(s)/event(s). If there are more than one alarm(s)/event(s), the alarm(s)/

event(s) will be listed in order of occurrence.

To view possible causes for alarm/event, press the

HELP key again after the alarm/event is displayed. Refer to

table below for an overview of the possible alarm/event and their respective causes.

Press the

CLEAR key to return to the main screen. After addressing the source of the alarm/event, press

RESET to re-start the system and/or clear the alarm/event.

The controller logs alarm/event as they occur to aid in troubleshooting unobserved alarm/event. Refer to

Section 6.14.0 for alarm/event logging information

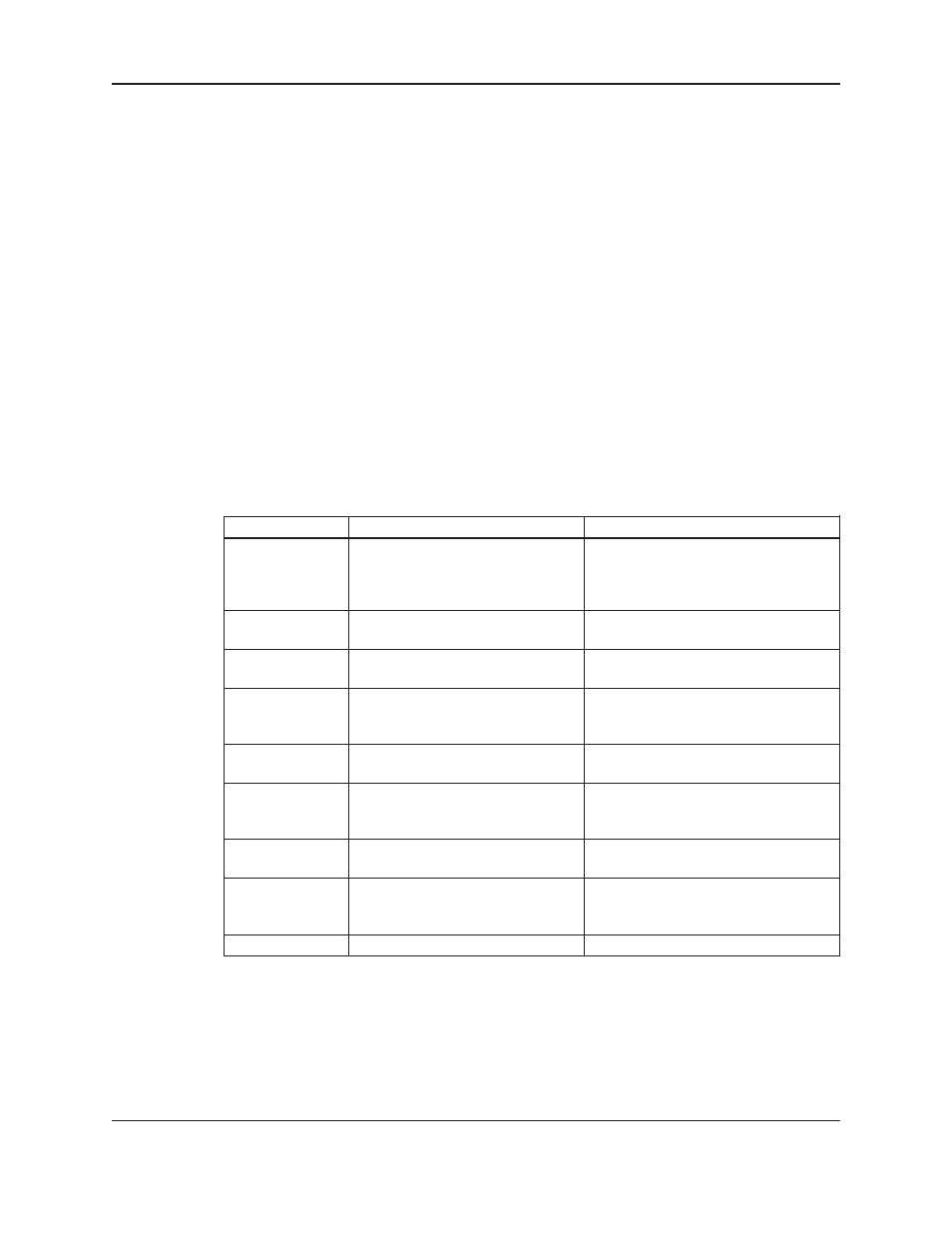

Help Screen Alarm Help/Help Screen Display

Detailed Description

VFD

Failure

“Check

communication

wiring,

and

VFD

display”

High Discharge

“Check discharge pressure –

manual RESET required”

Low Discharge

“Check discharge pressure”

Low Suction

“Check setting of the low suction

switch” or low suction settings in the

ALARM/EVENTS set up

Low Water

“Check setting of level switch”

NFSD

“System will restart automatically

when flow occurs”

Sensor Fail

“Check wiring, piping, polarity,

continuity”

Sensor Reading

“Check wiring of both sensors, and

Drift

compare the pressure reading of both

sensors with pressure gauge ”

Low Battery

Replace OIP battery

Replace OIP battery

The controller is not receiving a closed run

signal from VFD number X after it has been

given a start command or communication

failure or VFD fault

Check the pressure setting in the setup

menu.

Check the pressure setting in the setup

menu.

Check for open or closed contacts and low

suction settings, refer to wire diagram for

proper connection

Check for open or closed contacts, refer to

wire diagram for proper connection.

Check the Reset PSI Drop value and the

pressure sensor connections, refer to the

wire diagram.

The controller is not receiving the proper

4-20mA

“Check wiring of both sensors, and compare

the pressure reading of both sensors with

pressure gauge ”