6a digital picodlynx, Non-isolated dc-dc power modules, Data sheet – GE Industrial Solutions 6A Digital PicoDLynx User Manual

Page 39

GE

Data Sheet

6A Digital PicoDLynx

TM

: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.45Vdc to 5.5Vdc output; 6A Output Current

April 29, 2013

©2013 General Electric Company. All rights reserved.

Page 39

Surface Mount Information

Pick and Place

The 6A Digital PicoDLynx

TM

modules use an open frame

construction and are designed for a fully automated

assembly process. The modules are fitted with a label

designed to provide a large surface area for pick and place

operations. The label meets all the requirements for surface

mount processing, as well as safety standards, and is able to

withstand reflow temperatures of up to 300

o

C. The label also

carries product information such as product code, serial

number and the location of manufacture.

Nozzle Recommendations

The module weight has been kept to a minimum by using

open frame construction. Variables such as nozzle size, tip

style, vacuum pressure and placement speed should be

considered to optimize this process. The minimum

recommended inside nozzle diameter for reliable operation is

3mm. The maximum nozzle outer diameter, which will safely

fit within the allowable component spacing, is 7 mm.

Bottom Side / First Side Assembly

This module is not recommended for assembly on the

bottom side of a customer board. If such an assembly is

attempted, components may fall off the module during the

second reflow process.

Lead Free Soldering

The 12VDigital PicoDLynx

TM

6A modules are lead-free (Pb-

free) and RoHS compliant and are both forward and

backward compatible in a Pb-free and a SnPb soldering

process. Failure to observe the instructions below may result

in the failure of or cause damage to the modules and can

adversely affect long-term reliability.

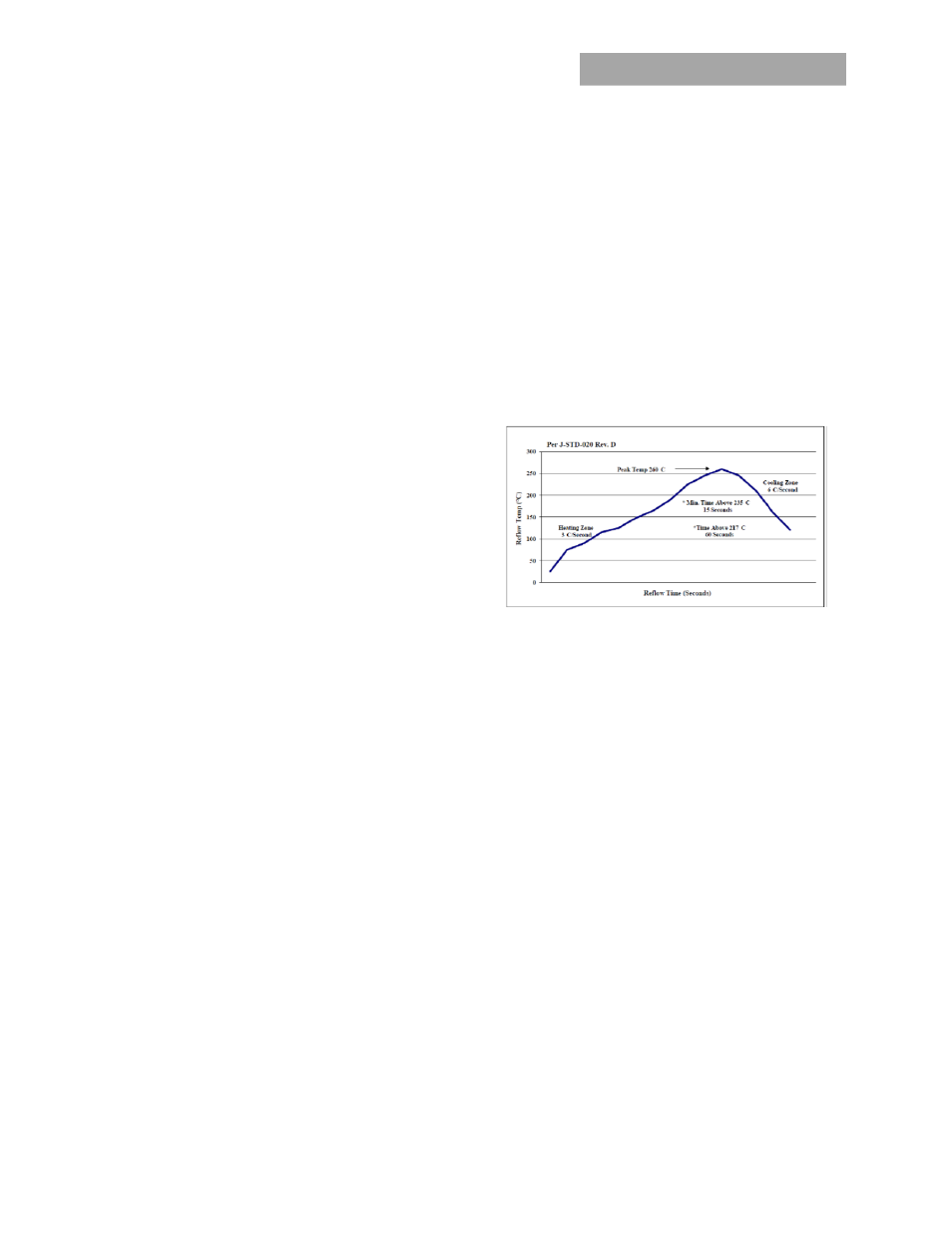

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. C

(Moisture/Reflow Sensitivity Classification for Nonhermetic

Solid State Surface Mount Devices) for both Pb-free solder

profiles and MSL classification procedures. This standard

provides a recommended forced-air-convection reflow

profile based on the volume and thickness of the package

(table 5-2). The suggested Pb-free solder paste is Sn/Ag/Cu

(SAC). The recommended linear reflow profile using Sn/Ag/Cu

solder is shown in Fig. 51.

Soldering outside of the

recommended profile requires testing to verify results and

performance.

It is recommended that the pad layout include a test pad

where the output pin is in the ground plane. The

thermocouple should be attached to this test pad since this

will be the coolest solder joints. The temperature of this point

should be:

Maximum peak temperature is 260 C.

Minimum temperature is 235 C.

Dwell time above 217 C: 60 seconds minimum Dwell time

above 235 C: 5 to 15 second

MSL Rating

The 6A Digital PicoDLynx

TM

modules have a MSL rating of 2a.

Storage and Handling

The recommended storage environment and handling

procedures for moisture-sensitive surface mount packages

is detailed in J-STD-033 Rev. B (Handling, Packing, Shipping

and Use of Moisture/Reflow Sensitive Surface Mount

Devices). Moisture barrier bags (MBB) with desiccant are

required for MSL ratings of 2 or greater. These sealed

packages should not be broken until time of use. Once the

original package is broken, the floor life of the product at

conditions of

≤ 30°C and 60% relative humidity varies

according to the MSL rating (see J-STD-033A). The shelf life

for dry packed SMT packages will be a minimum of 12

months from the bag seal date, when stored at the following

conditions: < 40° C, < 90% relative humidity.

Figure 51. Recommended linear reflow profile using

Sn/Ag/Cu solder.

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing. The result

of inadequate cleaning and drying can affect both the

reliability of a power module and the testability of the

finished circuit-board assembly. For guidance on

appropriate soldering, cleaning and drying procedures, refer

to Board Mounted Power Modules: Soldering and Cleaning

Application Note (AN04-001).