Pim400 series; atca board power input modules, Data sheet, Safety considerations – GE Industrial Solutions PIM400 Series User Manual

Page 14: Thermal considerations

GE

Data Sheet

PIM400 Series; ATCA Board Power Input Modules

-36 to -75 Vdc; 400W/10A

June 20, 2013

©2013 General Electric Company. All rights reserved.

Page 14

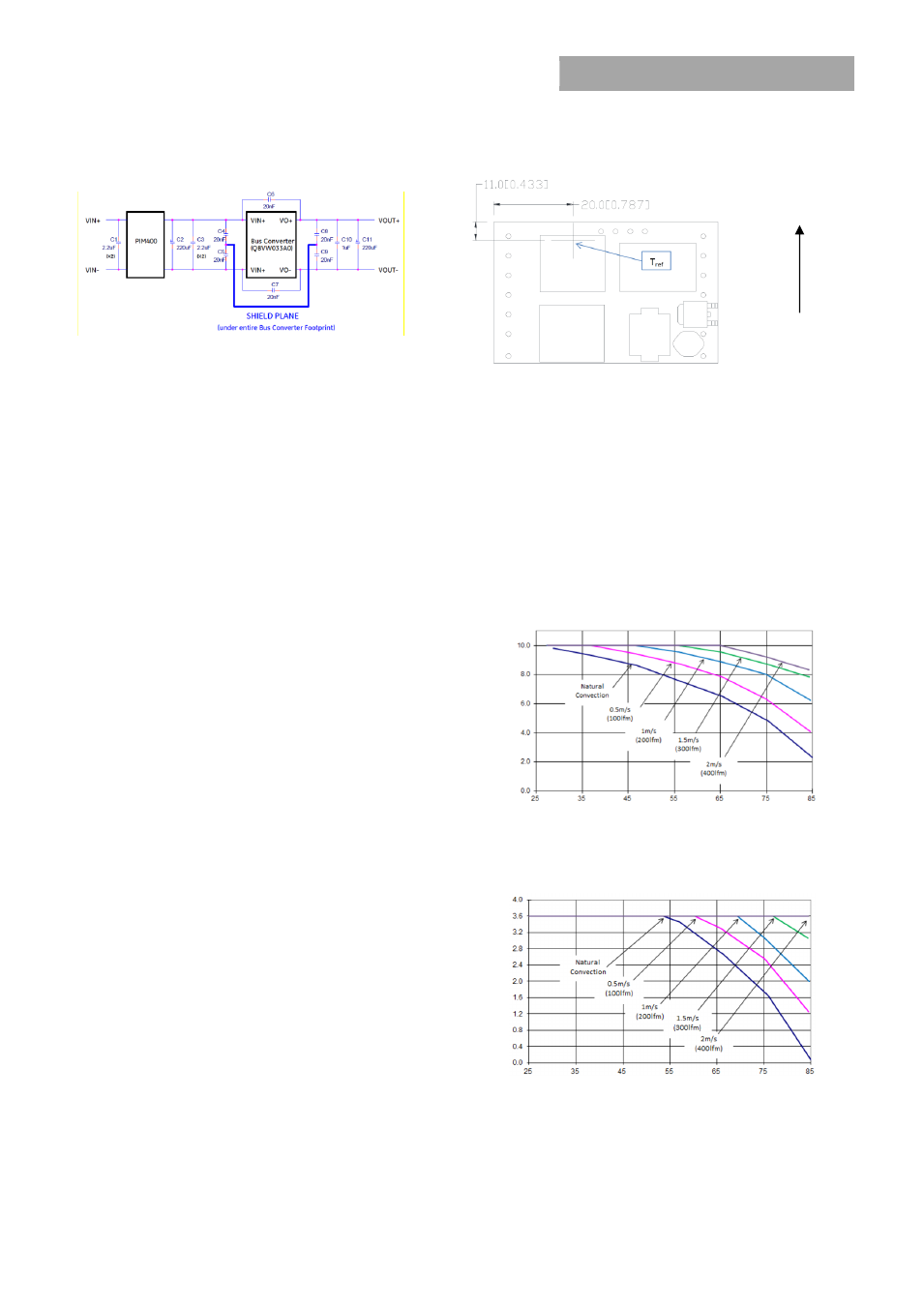

Figure 15. PIM400 & QBVW033A0 Bus Converter Test

setup schematic

For Safety and noise considerations, copper traces must not be

routed directly under the power module (PWB top layer). C_EMI

capacitors must make direct connections (preferably without

vias) to the bus converter (DC/DC) module pins with as much

copper width as possible. In case vias are necessary, allow for

multiple connections to the inner plane with vias placed outside

the footprint of the module. For additional layout guide-lines,

refer to GE’s FLT012A0Z Input Filter Module data sheet.

Safety Considerations

For safety-agency approval of the system in which the power

module is used, the power module must be installed in

compliance with the spacing and separation requirements of

the end-use safety agency standard, i.e. UL* 60950-1, 2

nd

Ed.

Recognized, CSA

†

C22.2 No. 60950-1-07 Certified, and VDE

‡

(EN60950-1, 2

nd

Ed.) Licensed

The power input to these units is to be provided with a

maximum of fast acting 20A fuses with a voltage rating of at

least 75Vdc.

Refer to “Thermal Consideration” section for additional safety

considerations.

Thermal Considerations

The power modules operate in a variety of thermal

environments; however, sufficient cooling should be provided

to help ensure reliable operation.

Considerations include ambient temperature, airflow, module

power dissipation, and the need for increased reliability. A

reduction in the operating temperature of the module will result

in an increase in reliability. The thermal data presented here is

based on physical measurements taken in a wind tunnel.

The thermal reference point, T

ref

,

used in the specifications is

shown in Figure 16. For reliable operation this temperature

should not exceed 130

o

C.

Figure 16. T

ref

Temperature Measurement Location.

Heat Transfer via Convection

Increased airflow over the module enhances the heat

transfer via convection. Derating curves showing the

maximum output current that can be delivered by

each module versus local ambient temperature (T

A

)

for natural convection and up to 2 m/s (400 lfm) forced airflow

are shown in Figures 17 & 18.

Please refer to the Application Note “Thermal Characterization

Process For Open-Frame Board-Mounted Power Modules” for a

detailed discussion of thermal aspects including maximum

device temperatures.

-

48

V

O

U

TP

UT

CUR

RE

N

T

(A

)

AMBIENT TEMEPERATURE, T

A

(

o

C

)

Figure 17. -48V Output Current Derating for the Module;

Airflow in the Transverse Direction from Pin7 to Pin1; Vin

=48V & 3.3V @ 1.5A.

3.

3V

O

UTP

UT

CUR

RE

N

T,

I

O

(A

)

AMBIENT TEMEPERATURE, T

A

(

o

C

)

Figure 18. 3.3V Output Current Derating for the Module;

Airflow in the Transverse Direction from Pin7 to Pin1; Vin

=48V & -48V Output current = 4A.

AIRFLOW