Thermal considerations – GE Industrial Solutions 12V Mega TLynx User Manual

Page 16

Data Sheet

May 4, 2012

12V Mega TLynx

TM

: Non-Isolated DC-DC Power Modules:

6.0 – 14Vdc Input; 0.8Vdc to 3.63Vdc Output; 30A output

current

LINEAGE

POWER

16

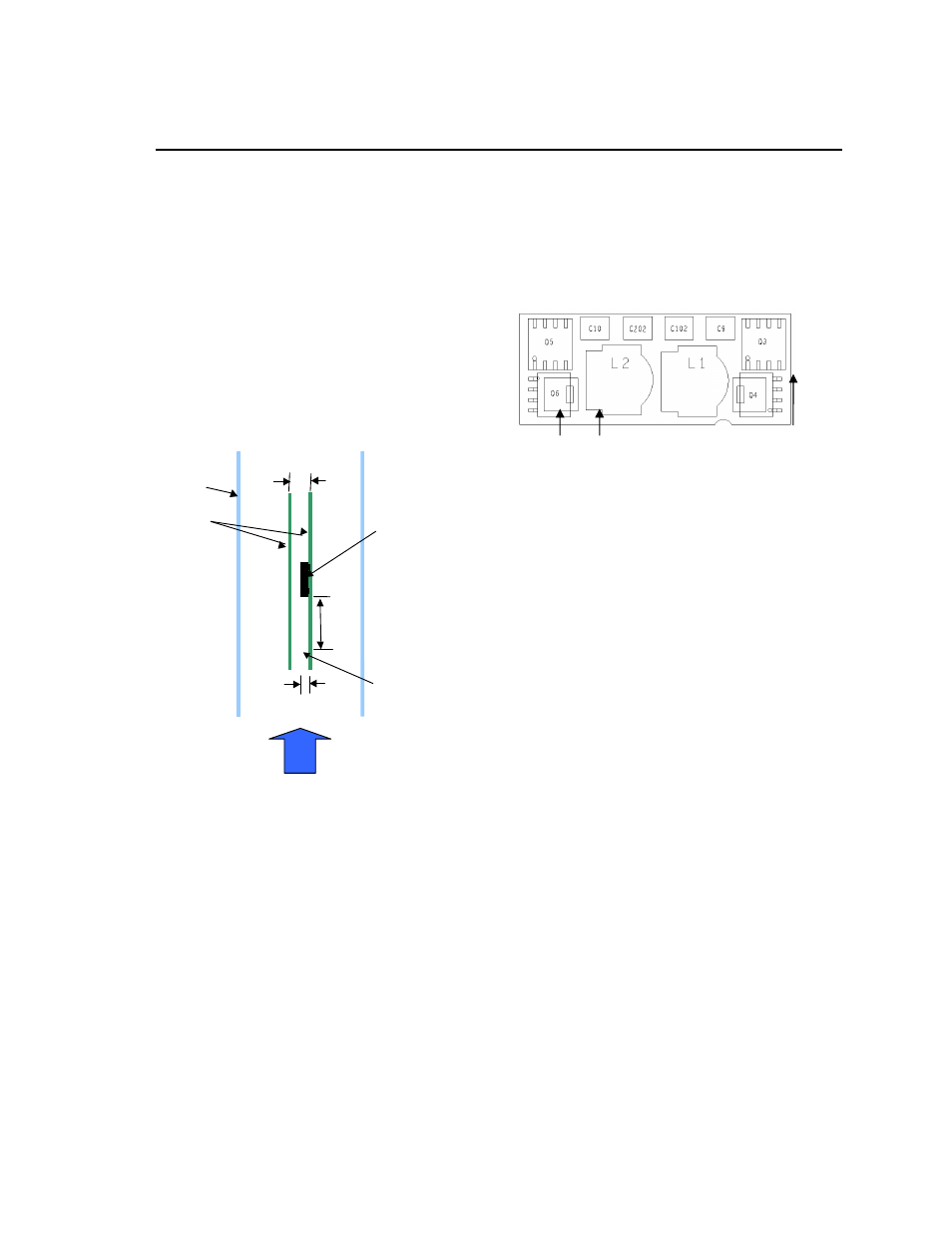

Thermal Considerations

Power modules operate in a variety of thermal

environments; however, sufficient cooling should

always be provided to help ensure reliable

operation.

Considerations include ambient temperature,

airflow, module power dissipation, and the need for

increased reliability. A reduction in the operating

temperature of the module will result in an increase

in reliability. The thermal data presented here is

based on physical measurements taken in a wind

tunnel. The test set-up is shown in Figure 35. Note

that the airflow is parallel to the short axis of the

module as shown in Figure 36. The derating data

applies to airflow in either direction of the module’s

short axis.

Figure 35. Thermal Test Setup.

The thermal reference points, T

ref

used in the

specifications is shown in Figure 36. For reliable

operation the temperatures at this point should not

exceed 130

o

C. The output power of the module

should not exceed the rated power of the module

(Vo,set x Io,max).

Please refer to the Application Note “Thermal

Characterization Process For Open-Frame Board-

Mounted Power Modules” for a detailed discussion

of thermal aspects including maximum device

temperatures.

Figure 36. Preferred airflow direction and location of

hot-spot of the module (Tref).

Air

flow

x

Power Module

Wind Tunnel

PWBs

12.7_

(0.50)

76.2_

(3.0)

Probe Location

for measuring

airflow and

ambient

temperature

25.4_

(1.0)

AIRFLOW

DIRECTION

Q6 & L2 Tref