Module – GE Industrial Solutions 12V Mega TLynx User Manual

Page 14

Data Sheet

May 4, 2012

12V Mega TLynx

TM

: Non-Isolated DC-DC Power Modules:

6.0 – 14Vdc Input; 0.8Vdc to 3.63Vdc Output; 30A output

current

LINEAGE

POWER

14

Good layout techniques should be observed when

using multiple units in parallel. To implement forced

load sharing, the following connections should be

made:

• The share pins of all units in parallel must be

connected together. The path of these

connections should be as direct as possible.

• All remote-sense pins should be connected to

the power bus at the same point, i.e., connect

all the SENSE

(+)

pins to the

(+)

side of the bus.

Close proximity and directness are necessary

for good noise immunity

Some special considerations apply for design of

converters in parallel operation:

• When sizing the number of modules required

for parallel operation, take note of the fact that

current sharing has some tolerance. In

addition, under transient condtions such as a

dynamic load change and during startup, all

converter output currents will not be equal. To

allow for such variation and avoid the likelihood

of a converter shutting off due to a current

overload, the total capacity of the paralleled

system should be no more than 75% of the

sum of the individual converters. As an

example, for a system of four 12V Mega

TLynx

TM

converters in parallel, the total current

drawn should be less that 75% of (4 x 30A) ,

i.e. less than 90A.

• All modules should be turned on and off

together. This is so that all modules come up at

the same time avoiding the problem of one

converter sourcing current into the other

leading to an overcurrent trip condition. To

ensure that all modules come up

simultaneously, the on/off pins of all paralleled

converters should be tied together and the

converters enabled and disabled using the

on/off pin.

• The share bus is not designed for redundant

operation and the system will be non-functional

upon failure of one of the unit when multiple

units are in parallel. In particular, if one of the

converters shuts down during operation, the

other converters may also shut down due to

their outputs hitting current limit. In such a

situation, unless a coordinated restart is

ensured, the system may never properly restart

since different converters will try to restart at

different times causing an overload condition

and subsequent shutdown. This situation can

be avoided by having an external output

voltage monitor circuit that detects a shutdown

condition and forces all converters to shut

down and restart together.

When not using the active load sharing feature,

share pins should be left unconnected.

Tunable Loop

TM

The 12V Mega TLynx

TM

modules have a new

feature that optimizes transient response of the

module called Tunable Loop

TM

.

External capacitors are usually added to the output

of the module for two reasons: to reduce output

ripple and noise (see Fig. 29) and to reduce output

voltage deviations from the steady-state value in the

presence of dynamic load current changes. Adding

external capacitance however affects the voltage

control loop of the module, typically causing the

loop to slow down with sluggish response. Larger

values of external capacitance could also cause the

module to become unstable.

The Tunable Loop

TM

allows the user to externally

adjust the voltage control loop to match the filter

network connected to the output of the module. The

Tunable Loop

TM

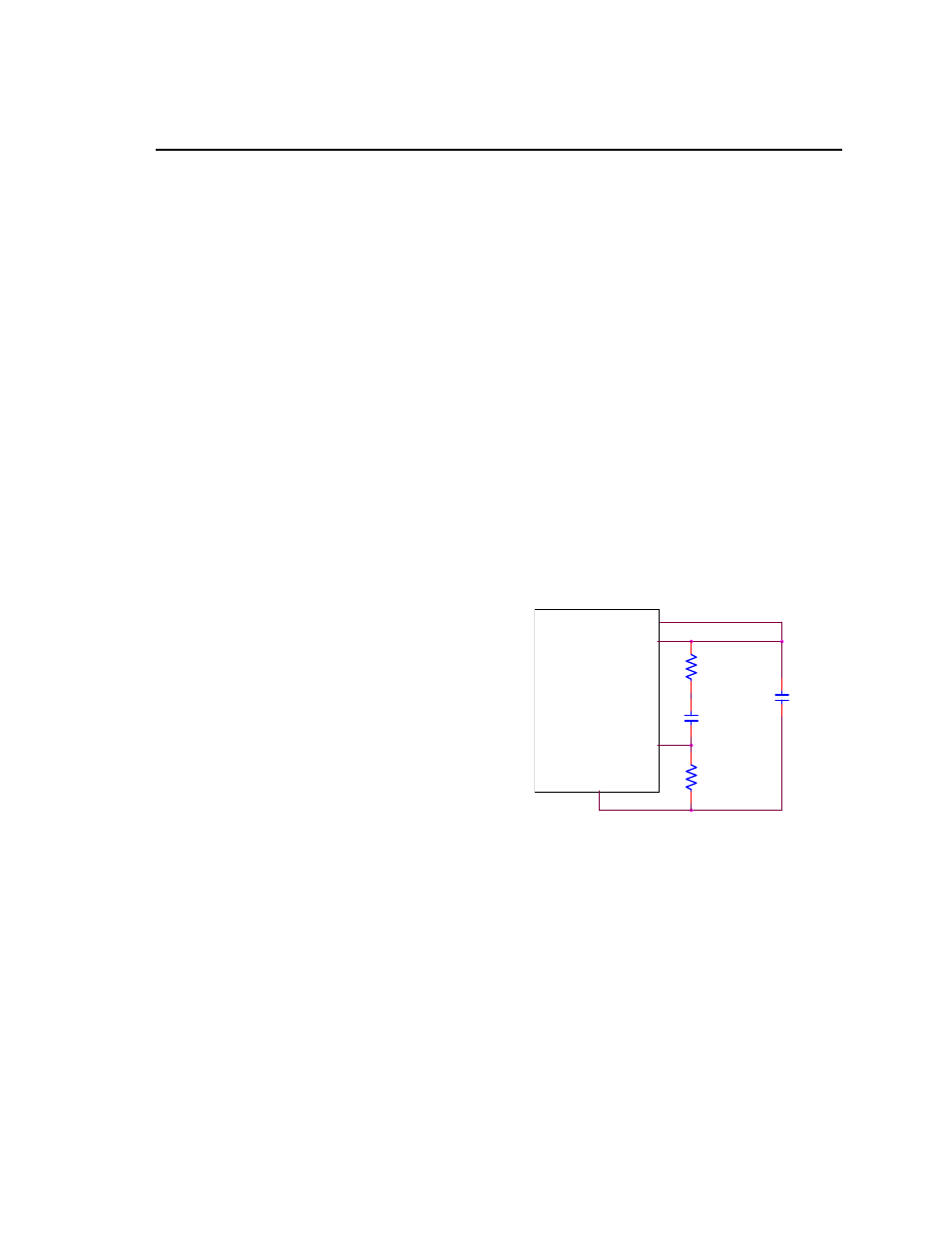

is implemented by connecting a

series R-C between the SENSE and TRIM pins of

the module, as shown in Fig. 34. This R-C allows

the user to externally adjust the voltage loop

feedback compensation of the module.

MODULE

VOUT

SENSE

TRIM

GND

RTUNE

CTUNE

RTrim

C O

Figure. 34. Circuit diagram showing connection

of R

TUME

and C

TUNE

to tune the control loop of

the module.

Recommended values of R

TUNE

and C

TUNE

for

different output capacitor combinations are given in

Tables 2 and 3. Table 2 shows the recommended

values of R

TUNE

and C

TUNE

for different values of

ceramic output capacitors up to 1000uF that might

be needed for an application to meet output ripple

and noise requirements. Selecting R

TUNE

and C

TUNE

according to Table 2 will ensure stable operation of

the module.

In applications with tight output voltage limits in the

presence of dynamic current loading, additional