GE Industrial Solutions Limitamp AR User Manual

Page 10

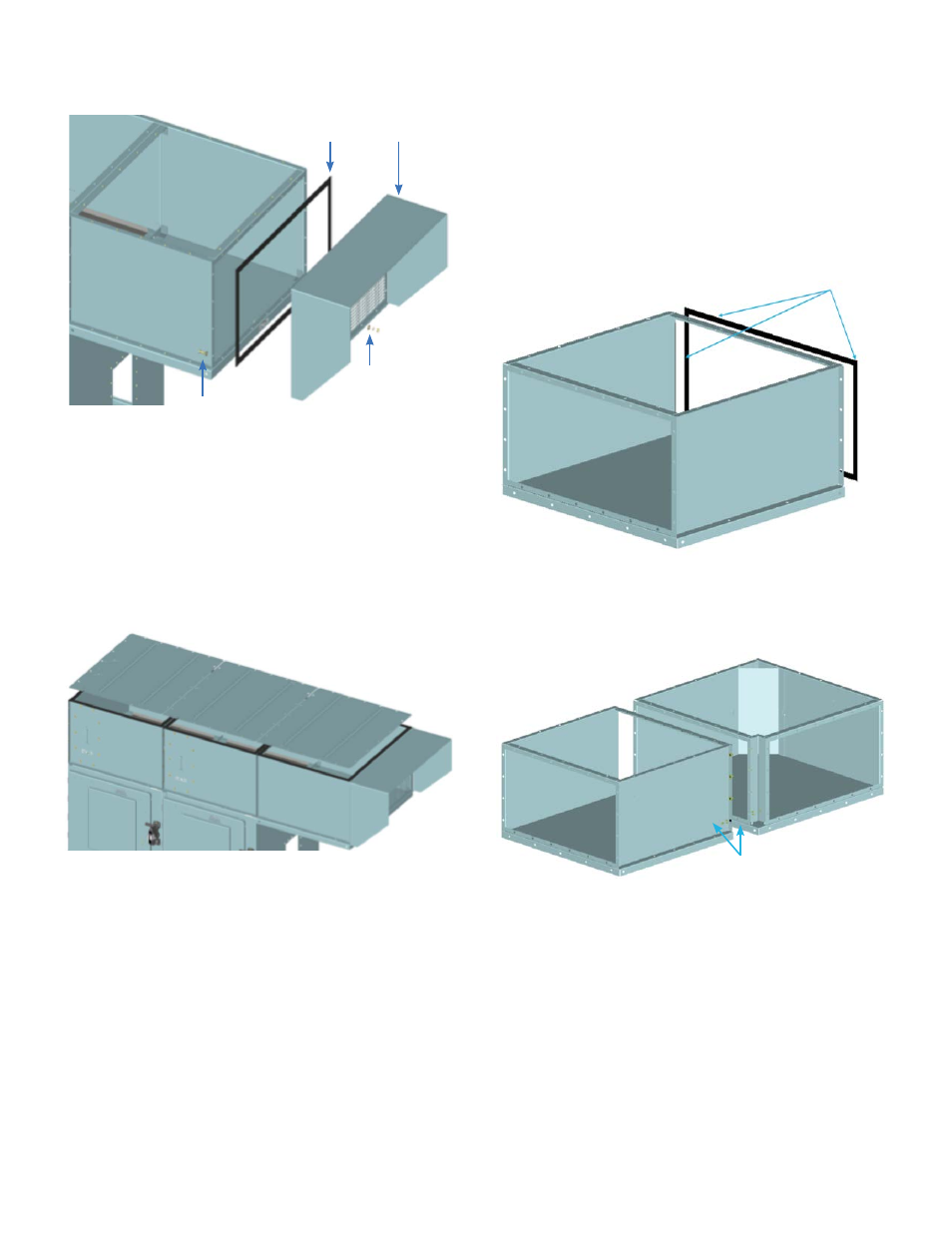

Step 11: Continue the assembly of extension plenums following

the same procedure. At the end of the extension plenum the

end duct assembly must be installed.

Figure 23. Assembly of end duct to the last segment

of the plenum.

Figure 24. Mount top covers using 3/8” diameter bolts.

Sealer

3/8” Hardware

End Duct

3/8” Hardware

If customer chooses to install their own version of end duct

segment then the duct must allow a minimum open exhaust

area of 428 in

2

.

Step 12: Once all the plenums are in place and bolted together

apply gasket around the perimeter of each plenum frame and

mount the cover plates using 3/8” hardware.

CR 194 One/Two-High Vacuum Limitamp

®

AR Control

Page 10

Turned Extension Plenum Installation

Guide (Front/Rear)

At the installation site, remove all separately packaged

components shipped within the Limitamp AR unit. Find the

Turned Plenum, mounting hardware and place them in the

work area.

Step 1: Remove top cover plate on existing extension plenum

for assembly. Apply sealer around perimeter of existing

extension plenum side flanges, where turned plenum (Front/

Rear) will be attached.

Sealer

Figure 25. How to apply sealer around perimeter of plenum.

Step 2: Install 3/8” diameter mounting bolts to attach turned

plenum (Front/Rear) to the extension plenum.

Figure 26. Use 3/8” hardware to mount turned plenum

(Front/Rear).

3/8” Hardware