Test configurations, Design considerations, Safety considerations – GE Industrial Solutions EBVW017A0S14R0 Series User Manual

Page 7: Input; 14.0v, Output; 17a output current

Data Sheet

April 11, 2013

EBVW017A0S14R0 Series Power Modules; DC-DC Converters

36-75V

dc

Input; 14.0V

dc

Output; 17A Output Current

LINEAGE

POWER

7

Test Configurations

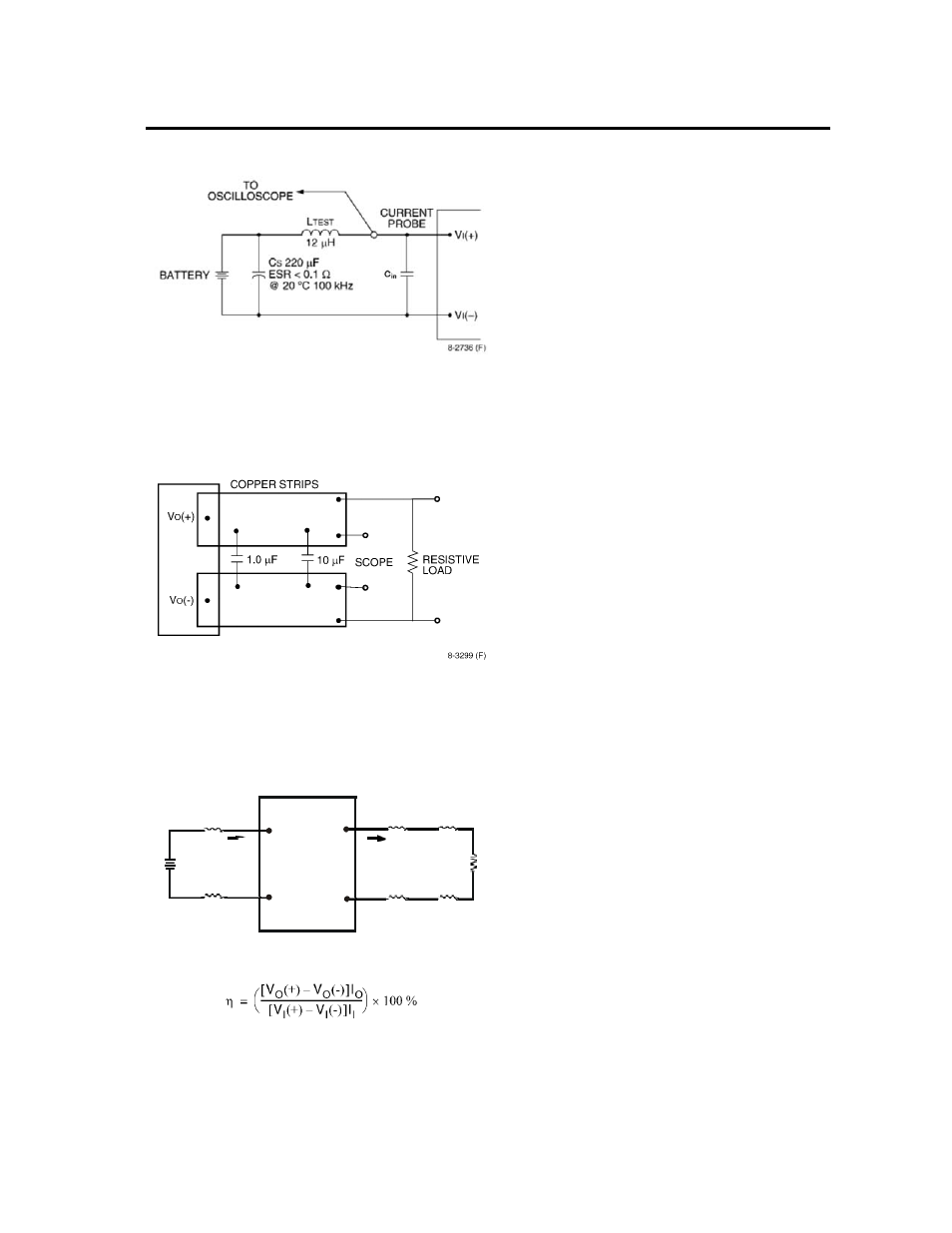

Note: Measure input reflected-ripple current with a simulated

source inductance (LTEST) of 12 µH. Capacitor CS offsets

possible battery impedance. Measure current as shown above.

Figure 12. Input Reflected Ripple Current Test Setup.

Note: Use a 1.0 µF ceramic capacitor and a 10 µF aluminum or

tantalum capacitor. Scope measurement should be made

using a BNC socket. Position the load between

51 mm and 76 mm (2 in. and 3 in.) from the module.

Figure 13. Output Ripple and Noise Test Setup.

Note: All measurements are taken at the module terminals. When

socketing, place Kelvin connections at module terminals to avoid

measurement errors due to socket contact resistance.

Figure 14. Output Voltage and Efficiency Test Setup.

Design Considerations

Input Source Impedance

The power module should be connected to a low

ac-impedance source. A highly inductive source impedance

can affect the stability of the power module. For the test

configuration in Figure 12, a 220μF electrolytic capacitor,

C

in

, (ESR<0.7

at 100kHz), mounted close to the power

module helps ensure the stability of the unit. If the module

is subjected to rapid on/off cycles, a 330μF input capacitor

is required. Consult the factory for further application

guidelines.

Safety Considerations

For safety-agency approval of the system in which the

power module is used, the power module must be installed

in compliance with the spacing and separation

requirements of the end-use safety agency standard, i.e.,

UL60950-1 2

nd

Ed., CSA C22.2 No. 60950-1 2

nd

Ed., and

VDE0805-1 EN60950-1 2

nd

Ed.

If the input source is non-SELV (ELV or a hazardous

voltage greater than 60 Vdc and less than or equal to

75Vdc), for the module’s output to be considered as

meeting the requirements for safety extra-low voltage

(SELV), all of the following must be true:

The input source is to be provided with reinforced

insulation from any other hazardous voltages,

including the ac mains.

One V

IN

pin and one V

OUT

pin are to be grounded, or

both the input and output pins are to be kept floating.

The input pins of the module are not operator

accessible.

Another SELV reliability test is conducted on the whole

system (combination of supply source and subject

module), as required by the safety agencies, to verify

that under a single fault, hazardous voltages do not

appear at the module’s output.

Note:

Do not ground either of the input pins of the module

without grounding one of the output pins. This may

allow a non-SELV voltage to appear between the

output pins and ground.

The power module has safety extra-low voltage (SELV)

outputs when all inputs are SELV.

The input to these units is to be provided with a maximum

15 A fast-acting (or time-delay) fuse in the unearthed lead.

The power module has internally generated voltages

exceeding safety extra-low voltage. Consideration should

be taken to restrict operator accessibility.

LOAD

CONTACT AND

SUPPLY

I

I

CONTACT

V

I

(+)

V

I

(–)

V

O1

DISTRIBUTION LOSSES

RESISTANCE

I

O

V

O2