Warning – Pro Series 30118 20K FIFTH WHEEL User Manual

Page 5

7. Install outer tubular handle (2) over solid inner handle (4) and pin together with cotter pin. Bend cotter pin to

hold in place. Check that latch bolt (8) is snug. Do not over tighten latch (3) must be able to move with firm hand

effort. Check to see that all retainer rings are in place.

8. Grease the pivot pin before the first trip and

1 Lubricate skid plate surface of the hitch (see figure on cover of Manual) with automotive type chassis grease or use a

BEFORE EACH TRIP:

PIVOT PIN GREASE ZERK

p

p

p

once a year thereafter.

1. Lubricate skid plate surface of the hitch (see figure on cover of Manual) with automotive type chassis grease or use a

plastic lube plate to provide a lubricated surface. Grease the 1-1/2” diameter pivot pin with the grease zerk provided. Use

engine oil to lubricate pivot points of moving parts within the hitch.

2. Plastic lube plates can be used to avoid messy grease. The plastic lube plate must not exceed 3/16

of an inch in thickness to ensure hitch will operate properly. Lube plates must be 10 inches in diameter or larger to

properly distribute king pin weight.

3. Before each trip or maneuver, operate the handle and check that the jaws open and close freely.

4. See that all hitch pull pins (# 25 on Fig. 20) are in place and the spring retaining pins (#26 on Fig. 20) are installed.

IMPORTANT: YOU ARE RESPONSIBLE FOR SAFE HITCHING AND UNHITCHING OPERATIONS. DO NOT RELY ON

OTHERS TO PERFORM YOUR DUTIES. YOU MUST PERSONALLY MAKE SURE THE FOLLOWING

HITCHING PROCEDURE:

STEPS ARE PERFORMED IN THE FOLLOWING ORDER!

WARNING:

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

1. Place blocks (sometimes called “chocks”) firmly against front and rear of each trailer wheel to prevent any possible

forward or rearward motion. DO NOT REMOVE BLOCKS UNTIL EACH OF THE FOLLOWING STEPS

AND THE PULL TEST HAVE BEEN COMPLETED. Lower tailgate if necessary.

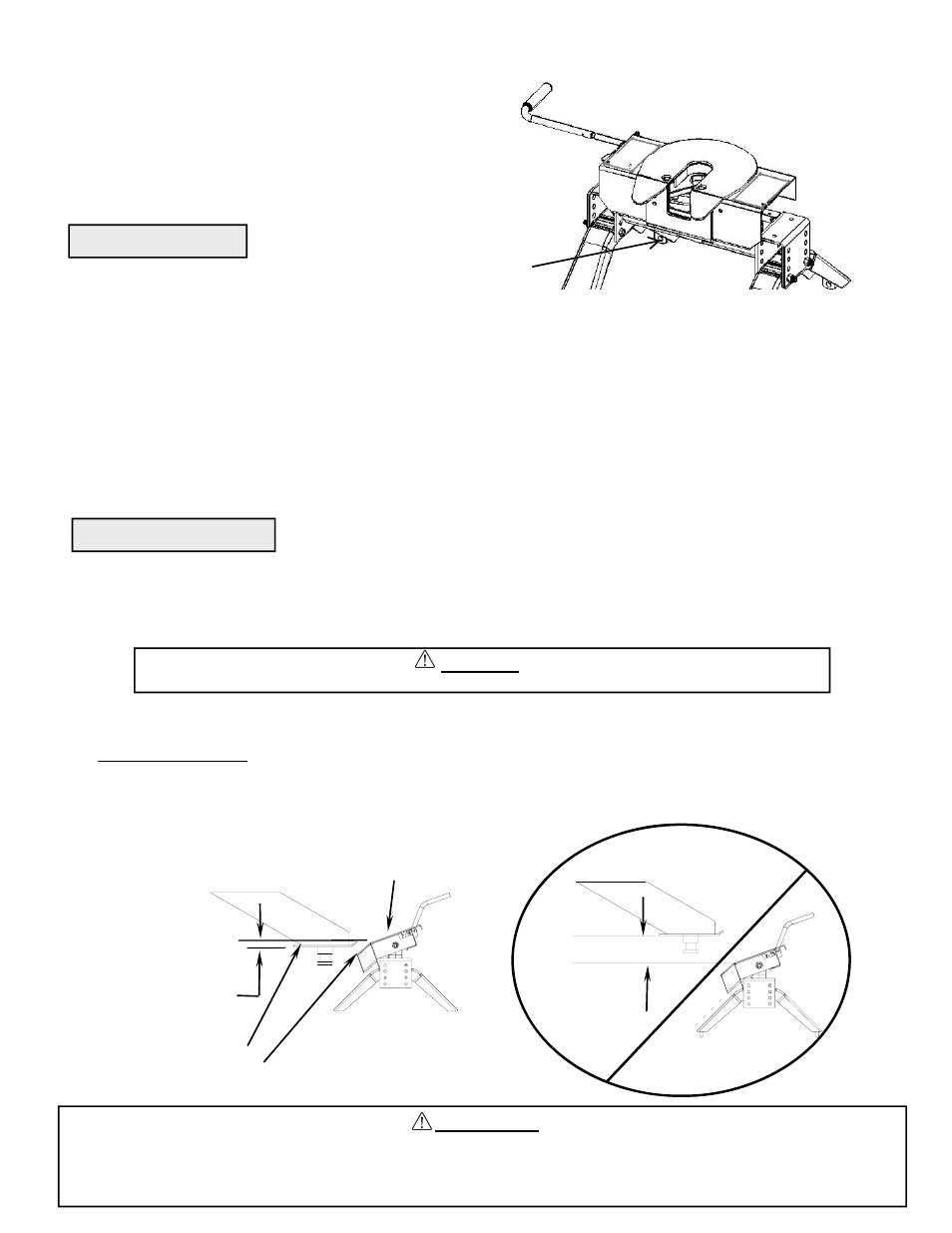

2. Using trailer jacks, adjust trailer height following the directions in the trailer manual so that bottom of trailer pin box (“A” in

Fig. 8) is ½ to 1 inch below skid plate (See “B” in Fig. 8). During the hitching maneuver, the bottom of the trailer pin box

should come in contact with skid plate ramp (“C” in Fig. 8).

Hitch Skid Plate (B)

Fig. 8

CORRECT

Bottom of Pin Box (A)

1/2 To 1 Inch Below

Hitch Skid Plate (B)

Skid Plate Ramp (C)

Bottom of Pin Box (A)

Bottom of Pin

Box Above

Hitch Skid Plate

Fig. 9

WRONG

30118IN 29JULY09B

PCN12190

©2009 CEQUENT PERFORMANCE PRODUCTS PRINTED IN XXXX

5

CORRECT

p ( )

WARNING:

Failure to follow this instruction may result in king pin being too high and coming to rest on top of closed jaws or

not completely inside jaws. (See Fig. 9). This could result in trailer separating from hitch. Trailer separation may

result in death or serious injury if anyone is under the trailer or between truck and trailer when separation occurs.