6 description of the control modes, 5 factory code example (factory: d2l) – R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Plus Service Manual User Manual

Page 9

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

9/83

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

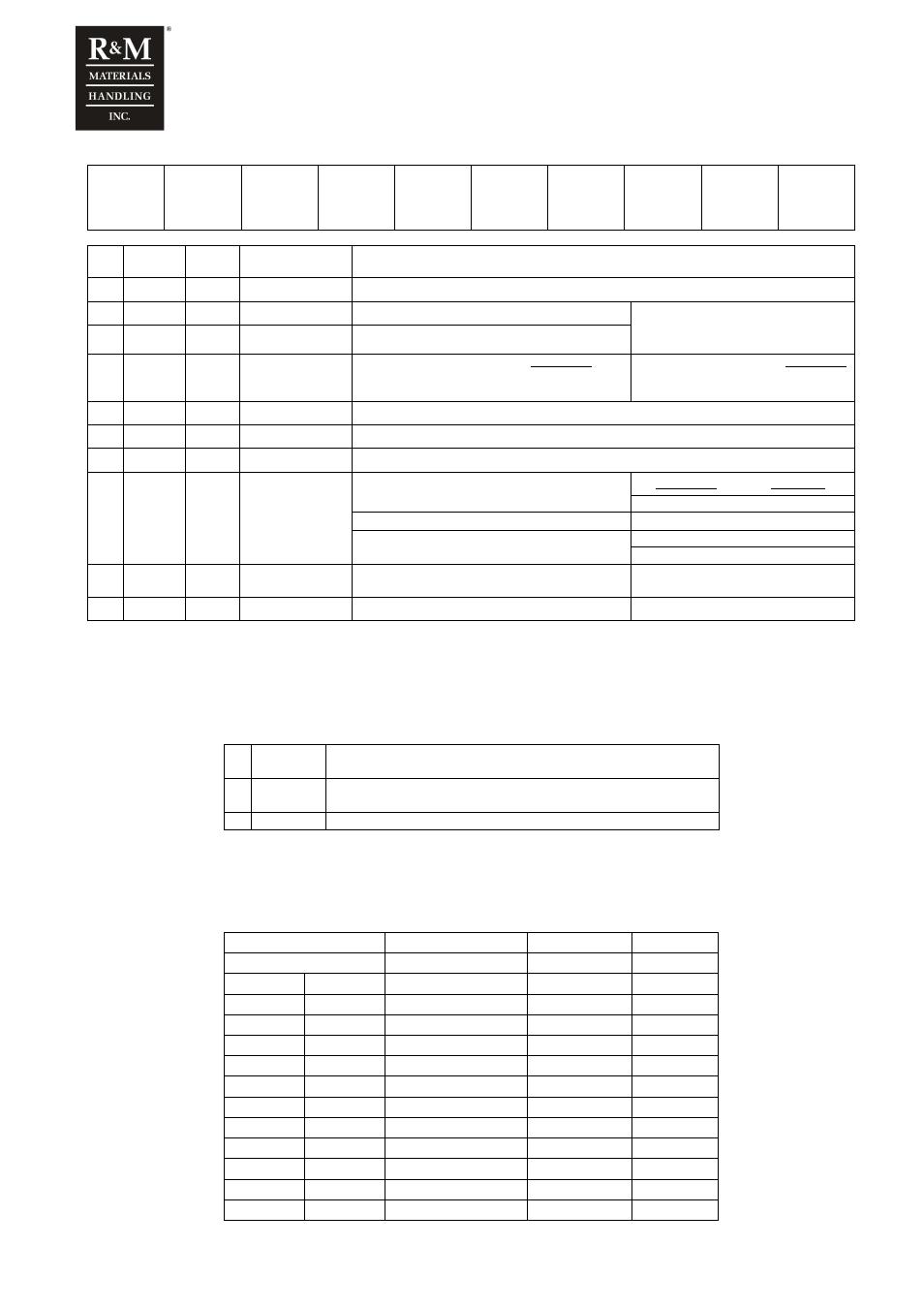

1.5 Factory code example (Factory: D2L)

D2L

007

F

V

52

A

0

N

1

L

HS01

(ELE83)

(ELE83)

(ELE02)

(ELE97)

(EL32)

1-3

4-6

7

8

9,10

11

12

13

14

15

Pos. Code

Feature

code

Feature

Available properties

1-3

D2L

HS01

Device name

D2L

4-6

007

(ELE83) Power rating class

002 - 055

ELE83 values are composed of two features,

Power rating class and Supply voltage.

e.g. 007F = ELE83 value

7

F

(ELE83) Supply voltage

F

380 – 500 VAC, 50/60 Hz

8

V

(ELE02) Control voltage

Y

P

42VAC, 50/60 Hz

48VAC, 50/60 Hz

ELE02 value

48

T

V

115VAC, 50/60 Hz

230VAC, 50/60 Hz

ELE02 value

115

230

9,10

52

Revision code

The latest revision may differ.

11

A

Braking resistor type A

External resistor

12

0

Mounting

0

Standard

13

N

(ELE97)

(EL32)

EMC level and

grounding

ELE97 value

EL32 value

S

Standard, without EMC filters (grounded network)

NONEU

GRD

N

EMC, Second environment (grounded network)

EU

GRD

0

IT network (non-grounded network)

NONEU

NONGRD

EU

NONGRD

14

1

HS27

Boards

1

5

Standard, with speed supervision

System bus, with speed supervision

15

L

Special

L

Varnished boards

1.6

Description of the control modes

There are three different control methods (command modes) available:

1

EP2

Electronic motor potentiometer function.

Stepless control using a 2-step controller.

2

EP3

Electronic motor potentiometer function.

Stepless control using a 3-step controller.

3

MS

Multistep control (4 steps)

The control mode of inverter is selected by parameter P2.1.4. See chapter Control methods. The parameters assigns

digital inputs S1, S2, OK, DIA3-DIA5 and DID1-DID5.It is not possible to chance the functions of the inputs separately.

The state of inputs can be checked from parameters V4.7.12 and V4.7.13. The input assignment according to the

selected mode is explained in the following table:

Control mode

EP

EP3

MS

Parameter P2.1.4

1

2

3

Signal

Terminal

S1

X1:8

S1

S1

S1

S2

X1:9

S2

S2

S2

OK

X1:7

OK

OK

OK

DIA3

X1:10

AP

AP

MS2

DIA4

X1:11

Not used

HOLD

MS3

DIA5

X1:12

Not used

not used

MS4

DID1

X1:38

FWE

FWE

FWE

DID2

X1:39

S11

S11

S11

DID3

X1:40

S21

S21

S21

DID4

X1:41

S12

S12

S12

DID5

X1:42

S22

S22

S22

Desired speed levels for multi-step control mode are selected with following parameters: