R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Plus Service Manual User Manual

Page 56

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

56/83

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

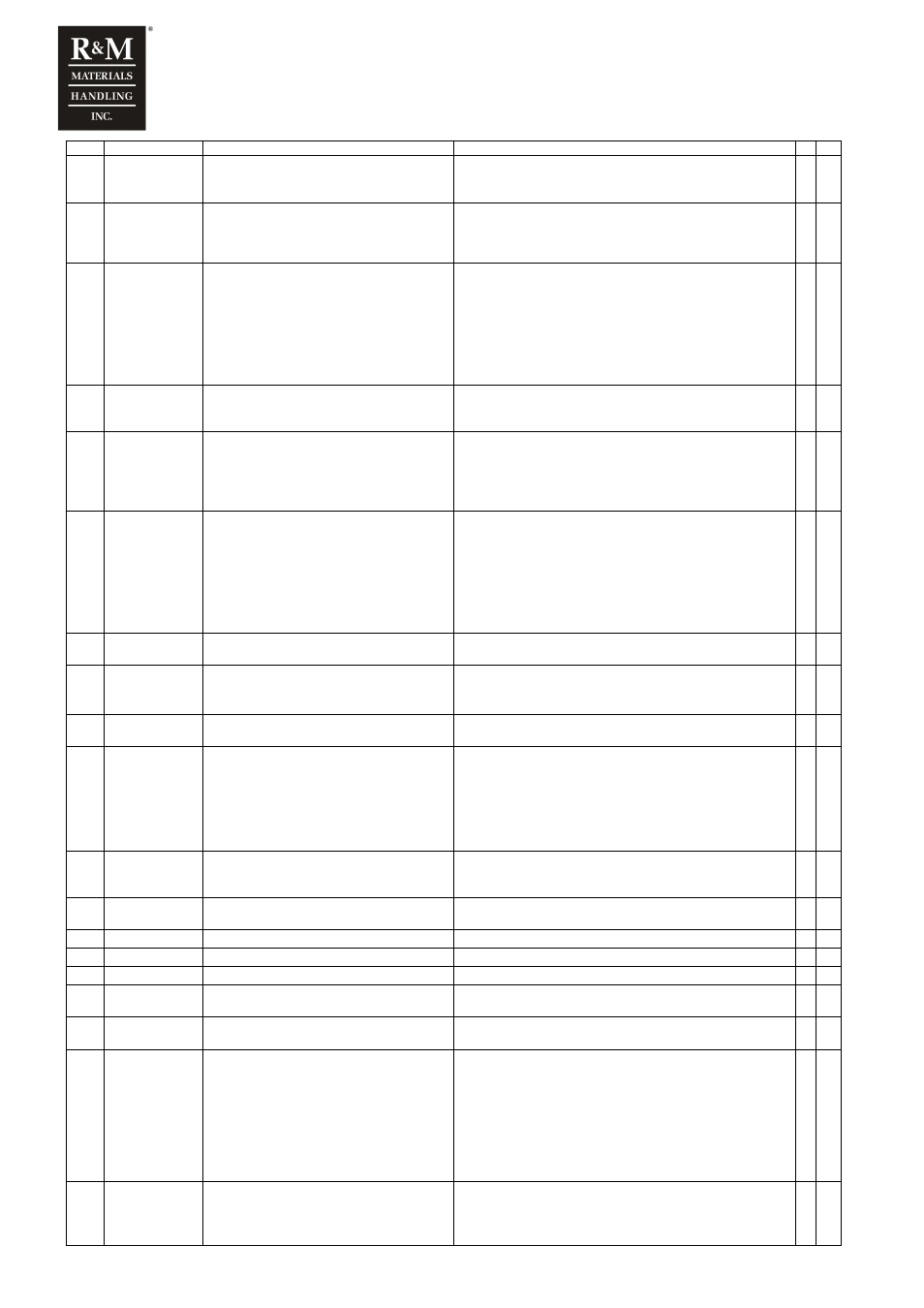

undervoltage trip

F 10 Input line

supervision

One input line phase is missing.

Check:

• supply voltage

• mains connection.

X

F 11 Output phase

supervision

Current supervision has sensed that at least

one of the motor phases has no current

Check:

• motor cable connections

• measure motor phase currents and compare to display

value

X

F 12 Braking

chopper

supervision

Braking chopper or braking resistor circuit

has failed. Test pulse measures transistor

collector voltage. Fault appears if

• braking resistor is broken

• braking chopper is broken

• braking resistor is not installed

Reset: switch power off and restart after the lamps of

display are off.

Check:

• braking resistor and insulation resistance

• measure braking transistor IGBT and free wheeling

diodes

• If resistor is OK, then the chopper is broken

• Contact authorized

service

X

F 13 Inverter

undertemperatu

re

Temperature of heat sink is below

acceptable operating level (-10°C /14°F)

Check

• ambient temperature

• cubicle heating

X

F 14 Inverter

overtemperatur

e

Temperature of heat sink is over acceptable

operating level

+90°C (194°F).

Overtemperature warning is issued when the

heat sink temperature exceeds +85°C (185°F)

Check:

• ambient temperature

• inverter cooling fan operation

• cooling air flow through heat sink

• heat sink is not dusty

X

F 22

F 23

EEPROM

checksum fault

Parameter save error

• interference fault

• component failure (control unit)

After power off the inverter will automatically reset

parameter settings. The drive does not work properly nor

enable driving after this fault.

Check:

• all parameter settings.

• +24V voltage output loading

• If the fault comes again, contact authorized

service

center.

X

F 24 Changed data

warning

Changes may have occurred in the different

counter data due to mains interruption

No special actions required. Take a critical attitude to the

counter data.

X

F 25 Microprocessor

watchdog-fault

• interference fault

• component failure (control unit)

Reset: switch power off and restart after the lamps of

display are off.

If the fault comes again, contact service.

X

F 26 Power Unit

Fault

X

F 31 IGBT

temperature

Too high temperature in IGBT. A hardware

temperature measurement has tripped.

Reset: switch power off and restart after the lamps of

keypad are off. Check:

• motor loading

• brake operation

• inverter heatsink

• inverter cooling fan operation

• environment temperature

X

F 32 Fan cooling

fault

Cooling fan of the frequency converter do

not work, when ON command has been

given

If the fault comes again, contact authorized

service.

X

F 35 Application

fault

Run-time exception in the application

program

Contact authorized service.

X

F 36 Control Unit

Faulty Control Unit.

Contact authorized service.

X

F 37 Device changed Option board changed.

Reset the fault

X

F 38 Device added

Option board added.

Reset the fault

X

F 39 Device

removed

Option board removed.

Reset the fault

X

F 40 Device

unknown

Unknown option board or drive.

Check board and drive type.

X

F 41 IGBT

tempetature

Too high temperature in IGBT transistors.

• long duration overload

• lowered cooling

• high environment temperature

Reset: switch power off and restart after the lamps of

keypad are off. Check:

• motor parameters

• u/f curve settings

• motor loading

• brake operation

• inverter heatsink

• inverter cooling fan operation

• environment temperature

X

F43

Encoder failure Encoder failure.

Subcodes:

• S1 = EA+/- is missing

• S2 = EB+/- is missing

Check:

• Encoder cabling

• Brake opening

• Encoder mechanical assembly

X