4 functional description, Operation when power is switched on, Normal operation – R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Plus Service Manual User Manual

Page 8: Other features

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

8/83

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

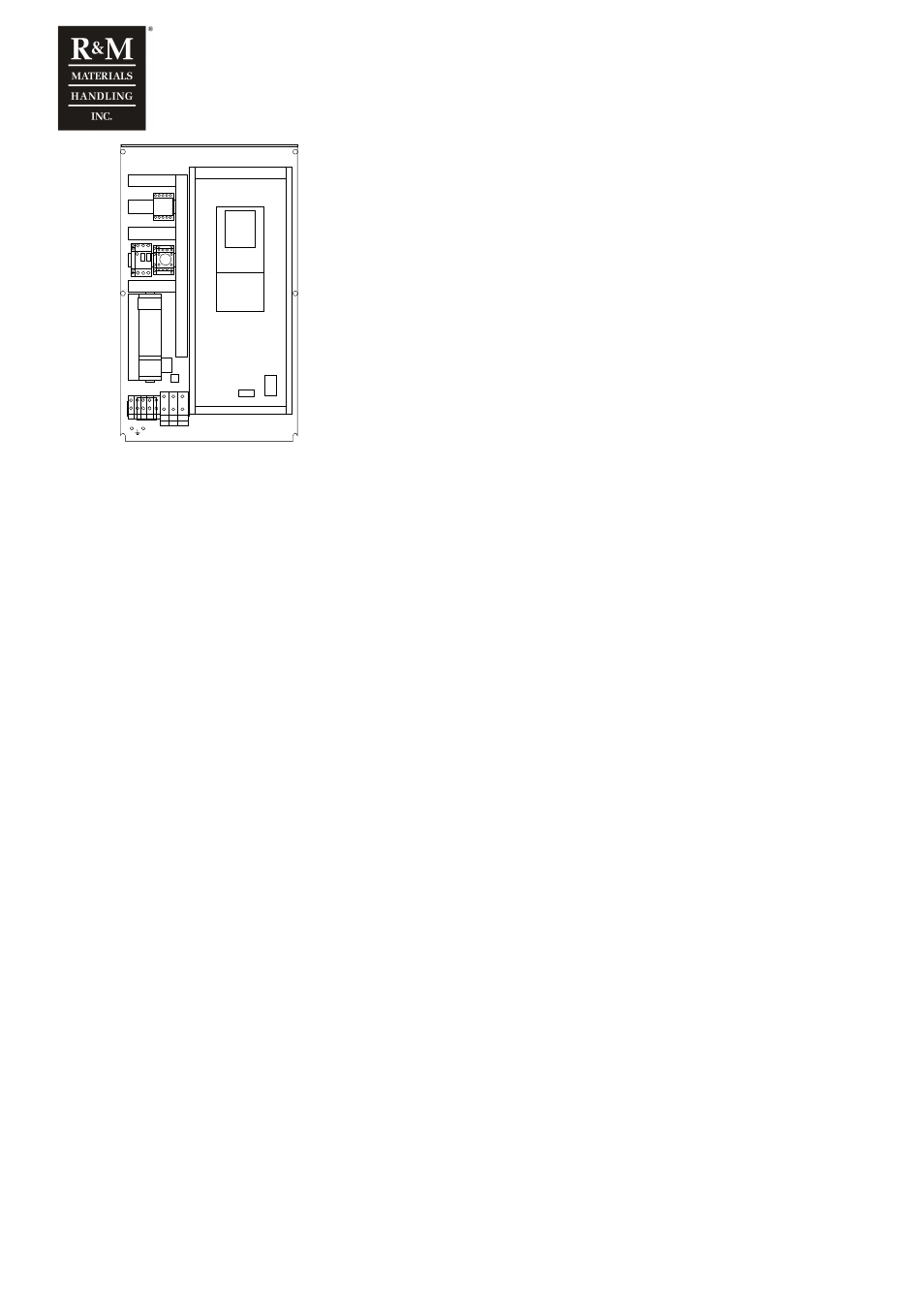

Z1

K7

F7

G1

X1

A1

CM1

Z2

Z3

1.4

Functional description

Operation when power is switched on

Stop limit switches S12 & S22 and slow down limit switches S11 & S21 are assumed to be normally closed, as well as the

emergency stop button ES.

The control voltage is supplied to X1:37. The main voltage is connected to inverter power supply and inverter wakes up. If the

control voltage is connected to RDY-signal and the fault circuit is OK, inverter is ready to operate in about 1-2 seconds.

If either of the direction signals S1 or S2 is on, the display shows F6 and driving can begin only after the direction signals have

been off for a while.

Normal operation

For the description of the speed reference setting see chapter "Control methods".

Hoisting (lowering) starts when switch S1 (S2) closes. Closing the contact ROB2 on A1 energizes K7, which opens the brake (in

model 055 the brake can be controlled also by K71). Motor accelerates according to the acceleration ramp setting to the

selected speed.

When the switch S1 (S2) opens motor stops according to the deceleration ramp setting and the brake closes.

R1 dissipates the regenerated energy during lowering periods. The power supply to R1 is controlled by A1. If the braking

resistor fan(s) are included in external resistor unit, they start to operate when power is supplied to the braking resistors. The

cooling continues about 4-5 minutes after electrical braking to ensure that the temperature of the resistors drops below 150

°

C

(302

°

F).

Other features

Slowdown limit switches S11 and S21 provide position dependent frequency limiting.

Any reason which opens contact RDY, stops the operation of inverter.

In case of overload, motor overheating etc. the hoisting can be disabled by cutting the direction signal in terminal X1:8.

Thermistor relay function, which can be used when needed.

When the stop limit switch S12 or S22 opens, K7 (K71 in model 055F) de-energizes and the mechanical brake stops the motion.

Independent speed supervision unit, SSU

The speed measurement and supervision can be done either with encoder, bearing sensor or proximity switch. The measured

signals are square wave pulses. The frequency of the pulses is proportional to the speed of the motor and if the frequency is too

high, overspeed is detected. If there are no pulses a stall situation is detected. If the actual speed differs too much from the

supply frequency of the motor, the speed difference supervision stops the motion.

Proximity switch buffer amplifier A5 amplifies the sensor pulses and filters out disturbances. The amplifier is located

close to the sensor.