R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Plus Service Manual User Manual

Page 57

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

57/83

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

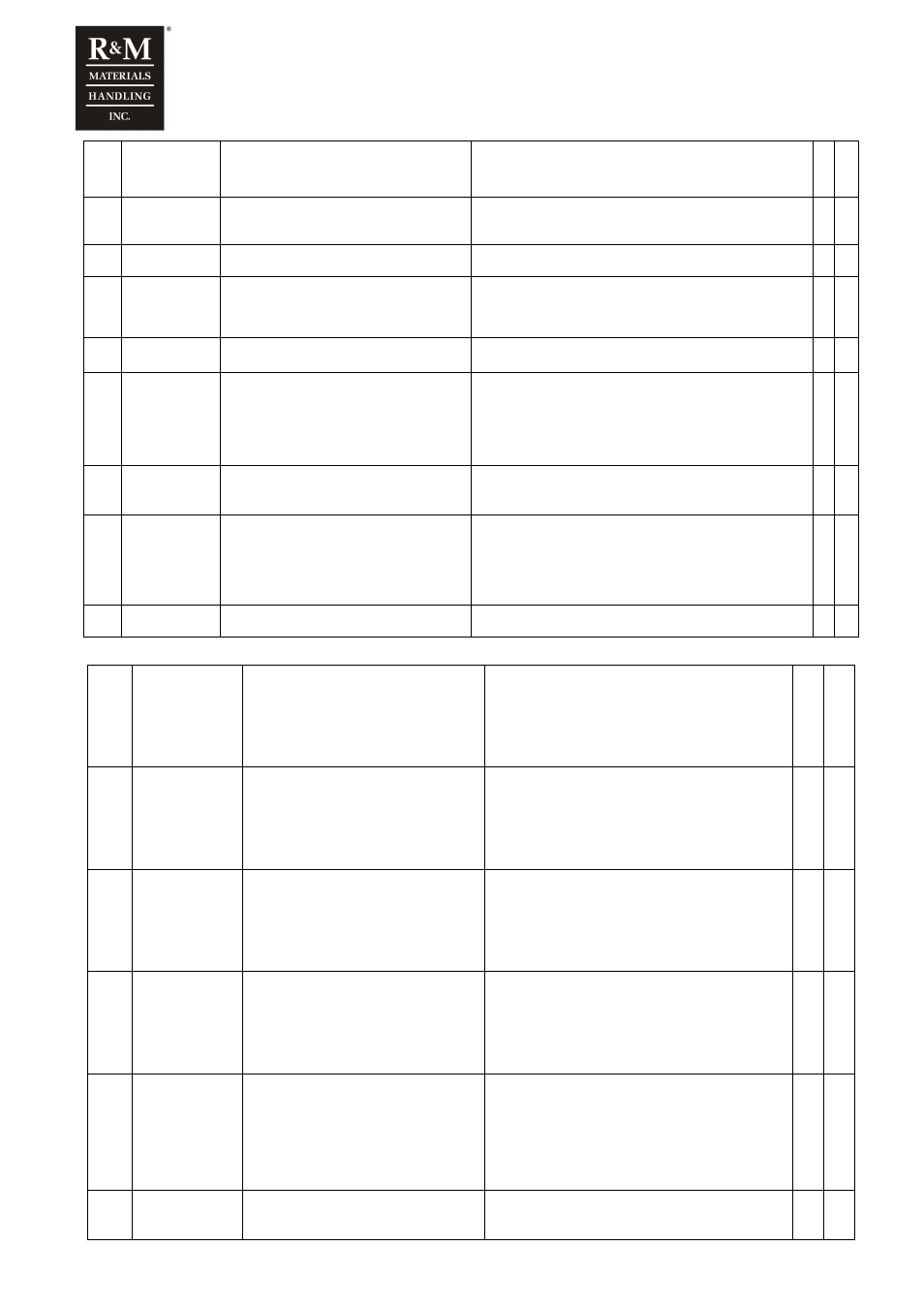

• S3 = Both EA+/- and EB+/- are missing

• S4 = EA+/- and EB+/- are crossconnected

•

S5 = SSU-board is missing or system load is

too high

• Encoder type and pulse number

F44

Device changed Option board or control unit has been

changed to different type or different power

rating

Reset the fault. Option board parameters or all parameters

are set up to default values.

X

F45

Device added

Option board of different type or drive of

different power rating added.

Reset the fault. Option board parameters or all parameters

are set up to default values.

X

F50

Reference

value fault

Analog input signal is out of selected range

1-9V or 2-10V

• Control cable is broken

• Signal source has failed

Check:

• Reference cable

• Reference source

X

F 51 Stop limit

Stop limit has tripped

Reset: keep controller at zero >300ms.

Ensure that fault disappears after leaving the stop limit.

X

F 55 Board Fault

Some of following board is missing:

• A = Basic I/O board

• B = Thermistor board

• D = Expansion board

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

• board slots A, B and D

• drive selection

• control mode

X

F 56 Generator side

current limit

Too short deceleration time

• generator side current limit

Reset has an additional 5 s time delay.

Check:

• deceleration time

X

F 57

Thermistor fault Thermistor input in relay / thermistor board

has detected motor overtemperature. Fault

appears when thermistor input has been

open over 1s.

Check:

• motor cooling and loading

• thermistor connection. If expansion board thermistor

input is not used, it should be shorted

• motor parameters

• the brake operation

X

F 60 Parameter fault Inverter has lost parameters. Drive selection

parameter has changed to 0 / none.

Download parameters from keypad

X

F 61

Overspeed Fault

SSU has tripped to Overspeed (hardware

supervision). Motor speed has increased

above overspeed detection level.

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

function and cabling

maximum frequency setting parameters

SSU settings

X

F 62

Speed Difference

Fault

SSU has tripped to Speed Difference

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

pulse sensor/encoder function and cabling

pulse sensor/encoder pulse number

speed difference supervision settings

X

F 63

Stall Supervision

Fault

SSU has tripped to Stall.

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

brake operation

pulse sensor/encoder function and cabling

stall supervision settings

X

F 64

SSU Relay Test

Fault

Relay in SSU board is damaged or SSU

relay is bypassed

Reset: switch power off and restart after the lamps of

keypad are off.

Check:

ES and RDY external connections

OK input operation

change SSU board

X

F 65

SSU Watchdog

SSU internal fault

interference fault between SSU board and

control board

component failure (control board or SSU

board)

Reset: switch power off and restart after the lamps of

display are off.

Check:

SSU status (System menu / System info / Expander

boards / C: SSU / status)

SSU LED’s

If the fault comes again, contact service

X

F 66

SSU Overspeed

Limit

SSU overspeed limit has been set over

140% of maximum frequency

Check:

set SSU overspeed limit under 140% of maximum

frequency

X