R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Plus Service Manual User Manual

Page 46

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

46/83

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

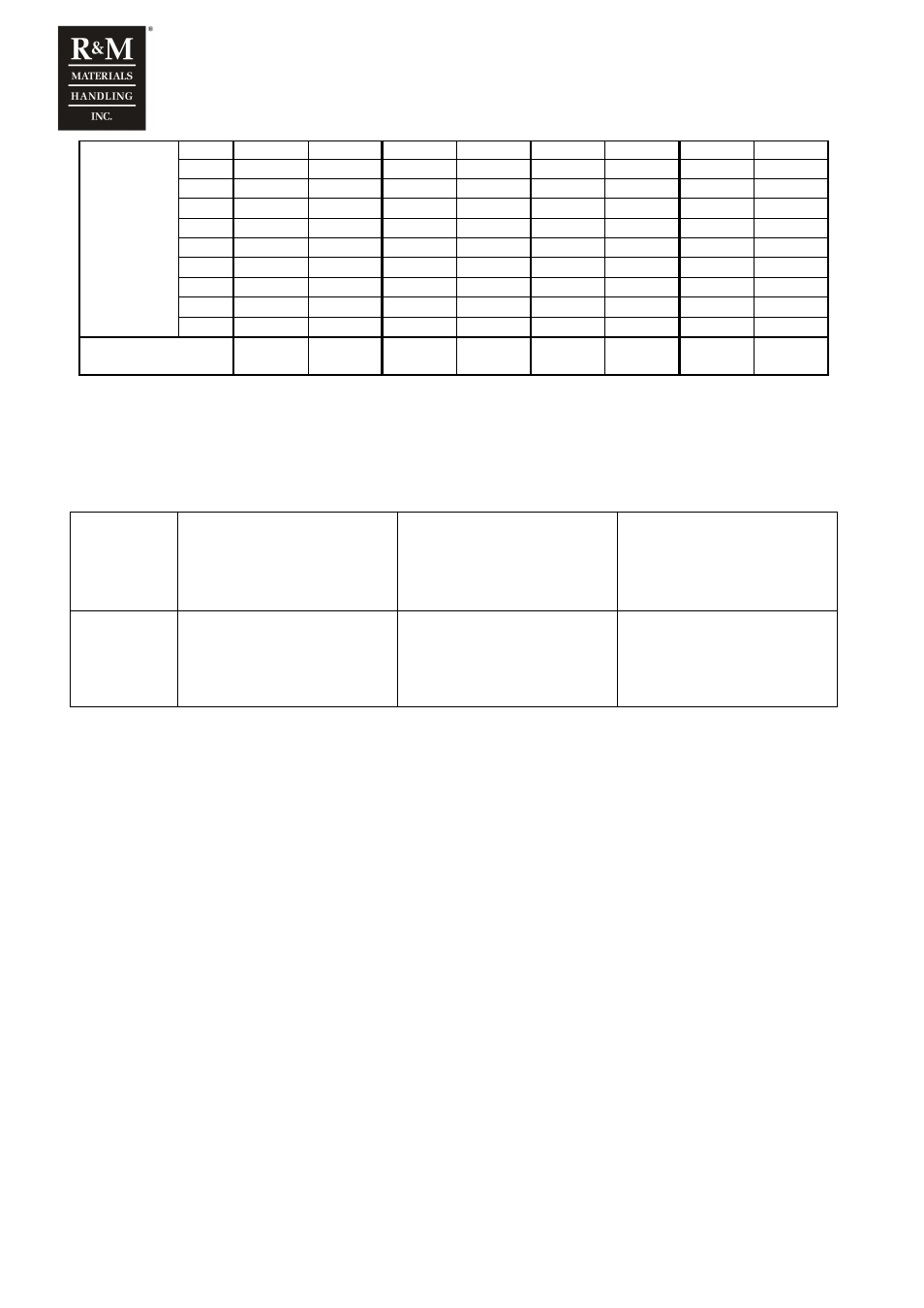

Tripping level

selection

S3/ESR

6

476

1625

951

3251

1902

6502

15217

52013

7

514

1755

1027

3511

2055

7022

16439

56174

8

555

1896

1109

3793

2218

7585

17744

60681

9

599

2048

1198

4096

2395

8192

19163

65536

A

647

2210

1296

4420

2587

8840

20696

70722

B

698

2381

1396

4763

2793

9526

22342

--

C

755

2586

1510

5163

3019

10326

24153

--

D

815

2793

1630

5585

3259

11171

26075

--

E

880

3012

1760

6024

3521

12047

28167

--

F

951

3234

1902

6467

3804

12935

30435

ESR

S2:4

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Range selection

S2:1 together with S1 are used for setting the tripping frequency level at normal speed.

S2:4 together with S3 are used for setting the tripping frequency level at ESR speed.

If ESR is not used, set S2:4 + S3 equal to S2:1 and S1.

Pulse frequency can be calculated from formula = Motor rpm x Pulses per rev / 60

Example

Normal use

A 3000 rpm motor with 32 pulses per

revolution has a full speed pulse

frequency of 1600 Hz.

Suitable maximum overspeed

detection level is 1600Hz + 25% =

2000Hz.

On the table the highest value under

2000Hz is 1902Hz. Suitable switch

settings are

S2-2=OFF and S2-3=OFF

S2-1=OFF and S2-4=OFF

S1=F and S3=F

Check from V4.8.1 that the detection

level is 1902Hz/1600Hz =118,9% of

nominal speed.

ESR use

If ESR is applied for 150% of nominal

speed, then the full ESR pulse

frequency is 1,5 * 1600Hz = 2400Hz.

Suitable maximum overspeed

detection level is 2400Hz + 25% =

3000Hz.

S2-2=OFF and S2-3=OFF are

according to normal speed settings.

On the table the highest value under

3000Hz is 2793Hz.

Correct switch settings are S2-4=ON

and S3=4.

Check from V4.8.2 that the detection

level is 2793Hz/2400Hz =116,4% of

ESR speed.

Encoder with 600 ppr or over needs both encoder channels connected.