Rpm display configuration, Light dim, Switch logic – Turbosmart BOOST CONTROLLERS – ELECTRONIC - e-Boost STREET 40psi – Complete Manual User Manual

Page 17: Auxiliary output, Boost correction

17

RPM DISPLAY CONFIGURATION

If you have connected the yellow RPM wire to an RPM signal from your ECU or negative terminal of an ignition coil you will need to

input the number of cylinders / rotors in order to configure the RPM signal correctly i.e. the number of pulses per revolution being picked

up from the RPM output of the ECU. The number of cylinders available is between 1 and 16. The RPM input can accept a square wave

signal between 3.5 and 12V. For Mazda Rotary engines, 13B and 20B engines can be configured as 4 and 6 cylinders respectively.

LIGHT DIM

The brightness of the display can be adjusted on a scale of 0

– 6. The display can also be dimmed automatically by earthing the orange

wire when the

vehicle’s light system is switched on and setting the scale to 0.

SWITCH LOGIC

The switch logic determines how the E-Boost Street switches between boost groups BG1 and BG2. It is factory set to internal switching

(ISP) where boost groups are changed by pushing the knob. Alternatively, boost groups can be switched remotely when the switch logic

is set to external switching (ESP). By earthing the green wire using a switch, you can toggle change from SP1 to SP2. Un-earthing this

wire will return the set point back to SP1.

AUXILIARY OUTPUT

The e-Boost Street has an auxiliary output function designed to control an auxiliary device once a certain boost pressure or RPM value

is reached i.e. water spray, water injection, warning light or nitrous controller. This circuit can be used to control a resistor type

automotive relay with a maximum current draw of 2 amps.

There are four options bOn, bOF, rOn and rOF. The boost setting on (bOn) and off (bOF) value will be entered in the units that are

currently selected for display. Between the bOn and bOF values the auxiliary output circuit will be closed and therefore will switch the

relay on.

The RPM setting on (rOn), and off (rOF) are entered as RPM x 100 e.g. if 5000 RPM is the desired setting the user will input 050.

Between the rOn and rOF values the auxiliary output circuit will be closed.

If the bOF or rOF is set to zero there will be no off and the circuit will remain closed until boost or RPM drops below the rOn or bOn

value. If using a boost setting only to switch the relay the RPM parameter values should be set to zero to turn off or vice versa.

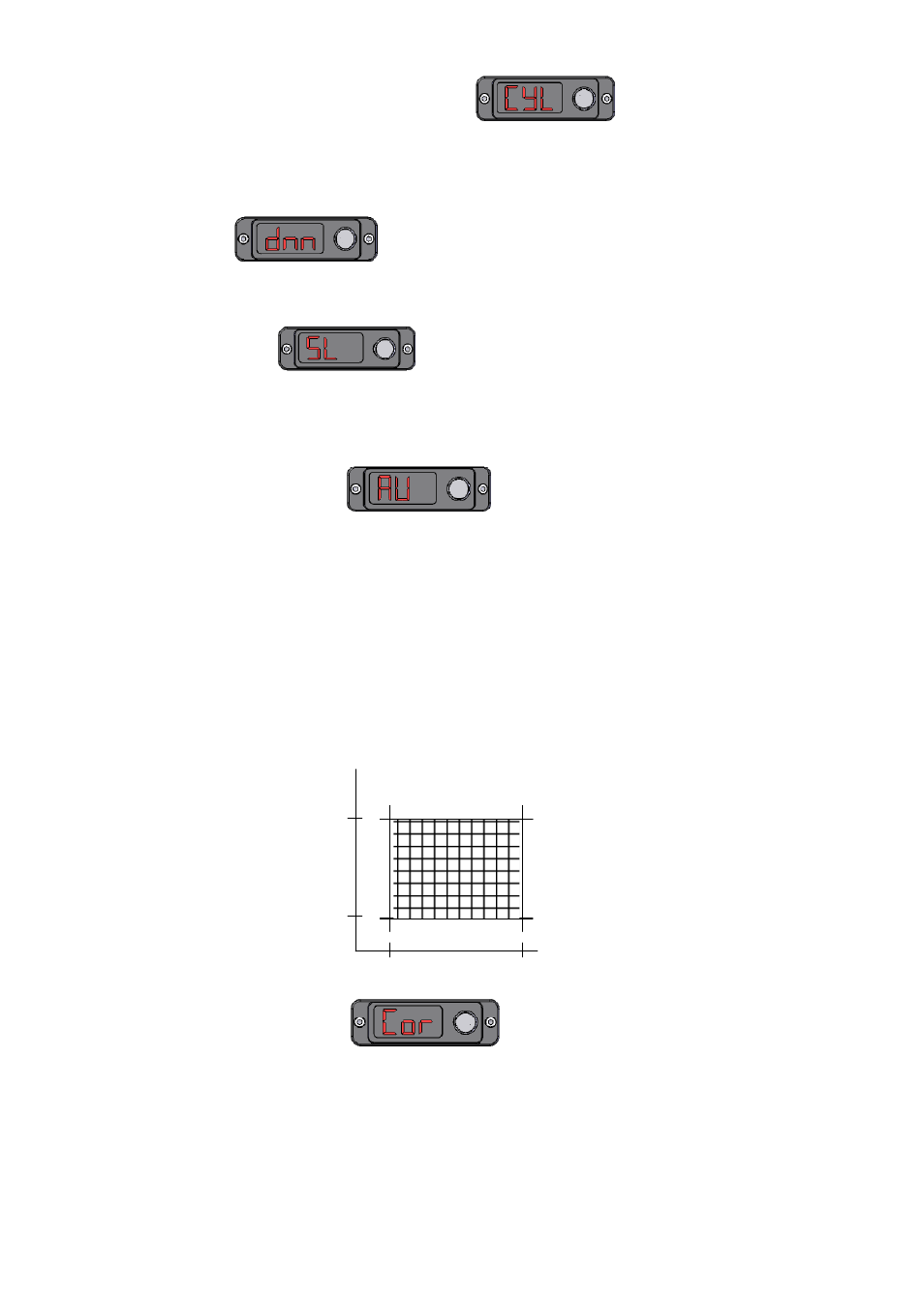

If using the auxiliary circuit as a nitrous controller, you can enter all four user definable parameters bOn, bOF, rOn, and rOF. The

auxiliary circuit will be closed when boost and RPM fall with the window created by these four parameters. That is when boost pressure

is between bOn and bOF AND when RPM is between rOn and rOF.

BOOST CORRECTION

This function is use to reduce or eliminate boost drop off at high RPM. Switching this function on will display the boost correction menu

in the boost group menu. This function is best performed on a chassis dyno where the graph of the boost curve can be displayed and

accurately interpreted.

The boost correction function requires 3 parameters to work; the START RPM, the END RPM and the correction factor.

START RPM (RP1): This is the engine RPM at which boost begins to drop off.

END RPM (RP2): This is the engine RPM at which you want to turn off the boost correction function, normally set at redline.

Correction factor (FAC): The percentage at which boost is dropping off between the START and END RPM.

Bof

Bon

Ron

Rof

AU on in

window