Veris Industries Badger 200 SERIES Install User Manual

Page 7

7

7) When connecting to a Badger Meter flow monitor/

transmitter, locate the section of terminal strip on the

monitor labeled “SENSOR INPUT” or “SENSOR”.

Connect the red wire to “IN”, "SIGNAL(+)" or "SIGNAL"

terminal and the black wire to “GND", "SIGNAL(-)”, or

"COM" terminal and the shield drain wire (if applicable)

to “SLD”.

8) When interfacing with other equipment, the signal wave

forms and power requirements are as shown in the

specifications section. Refer to technical bulletin DTB-

058 at www.badgermeter.com

Electrical Installation "High Temperature" sensors

1) Route a cable from the sensor to a Badger Meter flow

monitor/transmitter. The cable may be run up to 2000

feet, using 2-conductor shielded 20 AWG or larger

stranded copper wire. Be sure to leave enough flexibility

in the cable or conduit to allow for future service of sen-

sor, if necessary.

2) Connect to cable inside sensor electronic housing on

Series 220 sensors or attach to the sensor cable on the

Series 225/226 and connect with standard wire nuts.

3) When connecting to a Badger Meter flow monitor or

transmitter, locate the section of terminal strip on the

monitor labeled “SENSOR INPUT” or “SENSOR”.

Connect the red wire to “ IN”, "SIGNAL(+)" or

"SIGNAL" terminal and the black wire to “GND",

"SIGNAL(-)”, or "COM" terminal and the shield drain

wire (if applicable) to “SLD”.

4) When interfacing with other equipment, the signal wave

forms and power requirements are as shown in the

specifications section.

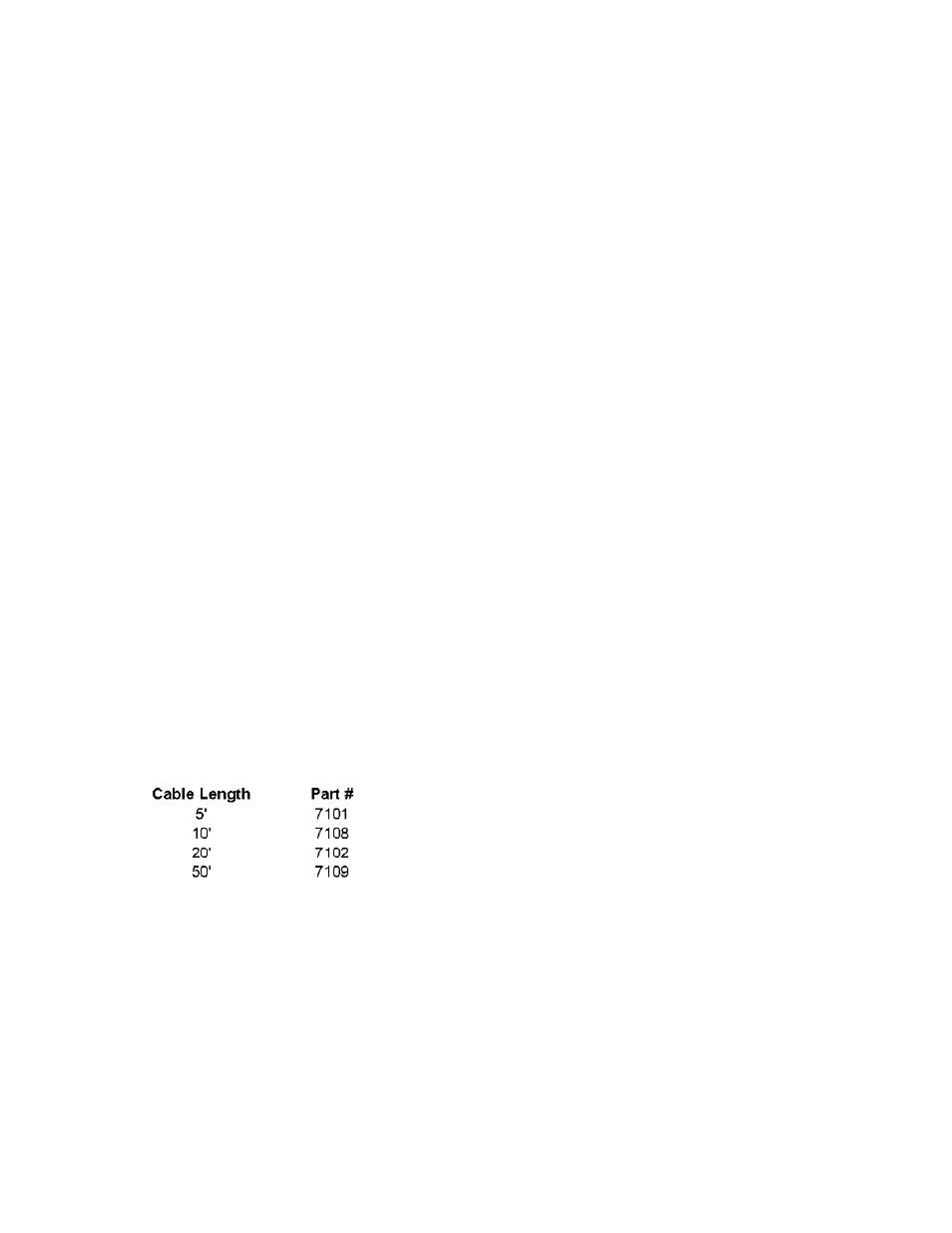

Electrical Installation "Magnetic" sensors

The magnetic sensor has a custom wire connector tha

connects to the series 1400 monitor only. The cable may be

extended up to 100 feet from the sensor. If extension cables

are needed they may be ordered from Badger Meter.

Electrical Installation (FM Sensors)

The Badger

®

Series 200 sensor is approved, as an entity, as

intrinsically safe when installed in conformance with Bad-

ger Meter installation drawings 06-480-001 or 06-480-002

(samples shown on Page 10) as specified on the blue label

identifying an intrinsically safe sensor.

Entity approval implies that only the sensor is approved as

intrinsically safe. Unless power supplies, equipment, and

instruments connected to the sensor are each rated either

explosion-proof or intrinsically safe, these devices cannot be

installed in a hazardous area. The referenced installation

drawing shows such apparatus located in a non-hazardous

location. Proper interfacing between the hazardous and non-

hazardous areas must be provided. It is of absolute impor-

tance that this interface be constructed and that all wiring be

performed by qualified contractors. To ensure the intrinsic

safety of the installation, the connection of the intrinsically

safe sensor to instruments and or power supplies must take

place using an approved intrinsically safe barrier located in a

non-hazardous area. These barriers, listed below, are read-

ily available from various suppliers.

Manufacturer:

Barrier:

Crouse-Hinds Spec 504

Cat No.SB19140M0715

Measurement Technology Ltd.

MTL 715+ 15 V

R Stahl Intrinspak

9001/1-158-150-10