Veris Industries Badger 200 SERIES Install User Manual

Page 5

5

the liquid flow direction. Tighten the positioning collar Allen

screws to lock the sensor tube assembly in position. Note:

As a backup to the flow direction arrow label on the tube

assembly, there is a smaller hole located beside one of the

sighting holes in the tube, to also indicate the upstream side

of the tube assembly.

If the pipe is depressurized and drained

1) Drill or cut a 1 7/8 inch hole in the pipe with a drill or

hole saw. Note the pipe wall thickness for use in calcu-

lating sensor assembly depth. A location on the top of

the pipe is best for overall performance and service life;

however, any radial location on the top half of the pipe is

acceptable. Allow a minimum of ten pipe diameters up-

stream and five downstream from the sensor of straight

unobstructed pipe to allow full development of the flow

profile.

2) Install either a service saddle or welded pipe fitting (2

inch female NPT) on the outside diameter of the pipe

over the 1 7/8 inch hole.

3) Install the Badger Meter isolation valve and nipple onto

the fitting using pipe thread sealant or Teflon

®

tape on all

threads.

4) Install the Badger Meter hex mounting adapter onto the

valve assembly. Use pipe thread sealant on the adapter.

Tighten the hex adapter so that no stud is aligned with

the center-line of the pipe. This could interfere with final

sensor alignment. Measure depth and set the height of

the nuts of the hex mounting adapter.

5) Open the bleed petcock valve on the hex adapter to re-

lieve the pressure as the sensor tube is installed. Care-

fully hand insert the Badger Meter hot tap flow sensor

tube into the hex mounting adapter. The sleeve should

be inserted past the top two O-rings in the adapter

(approx. 1 - 1 1/4 inches). Take care not to push the

tube in too far as the impeller could be damaged if it

strikes the closed valve.

6) Even if the sensor is installed with system drained,

Badger Meter recommends that a HTT, hot tap insertion/

removal tool be purchased for future service. This tools

allows the sensor tube assembly to be removed from the

pipe line without draining the entire loop where the sen-

sor is mounted.

7) In a fully depressurized and drained pipe, the sensor

tube assembly may be installed by hand. Carefully

and very slowly open the isolation valve to relieve any

pressure that may have built up. Fully open the isolation

valve. Push the sensor tube into the pipe with a slight

twisting motion. Guide the sensor collar holes over the

three hex adapter studs until the collar rests on the nuts.

Hex nuts should have been previously set to the correct

height. Install the three lock nuts onto these studs at the

top of the positioning collar and securely tighten.

8) Loosen the two set screws in the positioning collar with

a 3/32 inch Allen wrench. Align the sensor sight holes

along the pipe axis using the alignment rod provided in

the installation kit supplied with the sensor. Ensure that

the flow label arrow on the sensor matches the liquid

flow direction inside the pipe. Tighten the positioning col-

lar set screws. Note: As a backup to the flow label arrow,

there is a small hole located beside one of the sighting

holes to also indicate the upstream side of the sensor.

INSTALLATION INTO A PRESSURIZED PIPELINE USING

MODEL HTT.

For information on installing hot tap sensor with older 225H

consult technical bulletin DID-001

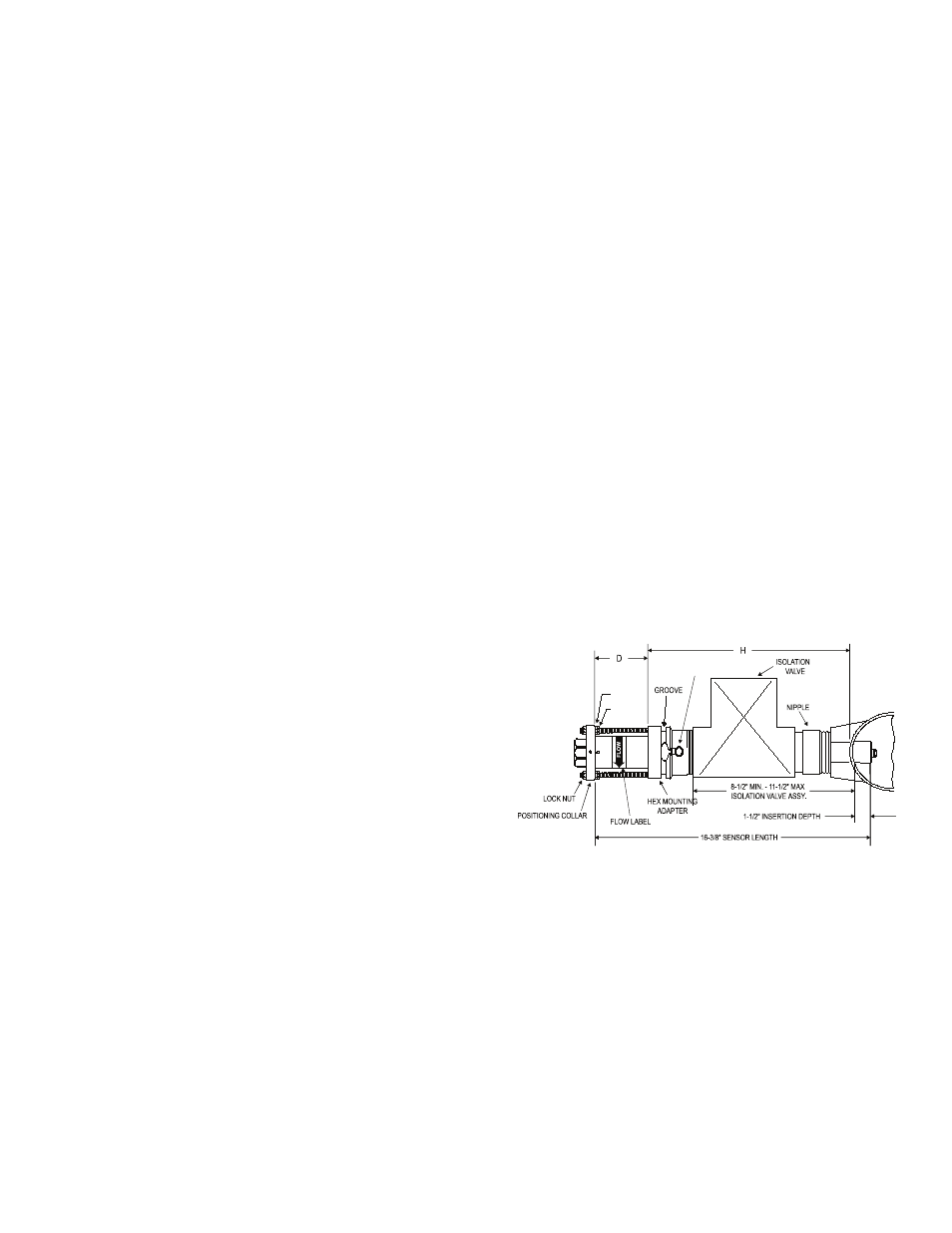

For pipe sizes 2½” and above; all Badger Meter sensors are

inserted 1 1/2” from the inside wall of the pipe. The insertion

depth is controlled by the position of the hex nuts on the

three threaded rods. The formula below defines the distance

between the top of the sensor hex mounting adaptor and

the bottom of the positioning collar (the top of the hex nut).

Reference Figure 3.

D = 16 3/8” - ( H + Pipe Wall Thickness + 1.5 “ )

Example: If sensor is installed in a 8 inch Sch 80 pipe with

a pipe wall thickness of 1/2 inch and the “H”

dimension is 10 inches then the calculation

would be as below:

D = 16 3/8 - ( 10 inches + 0.5 inches + 1.5 inches)

D = 4 3/8”

BLEED VALVE

HEX NUT

JAM NUT

Figure 3