Veris Industries Badger 200 SERIES Install User Manual

Page 3

3

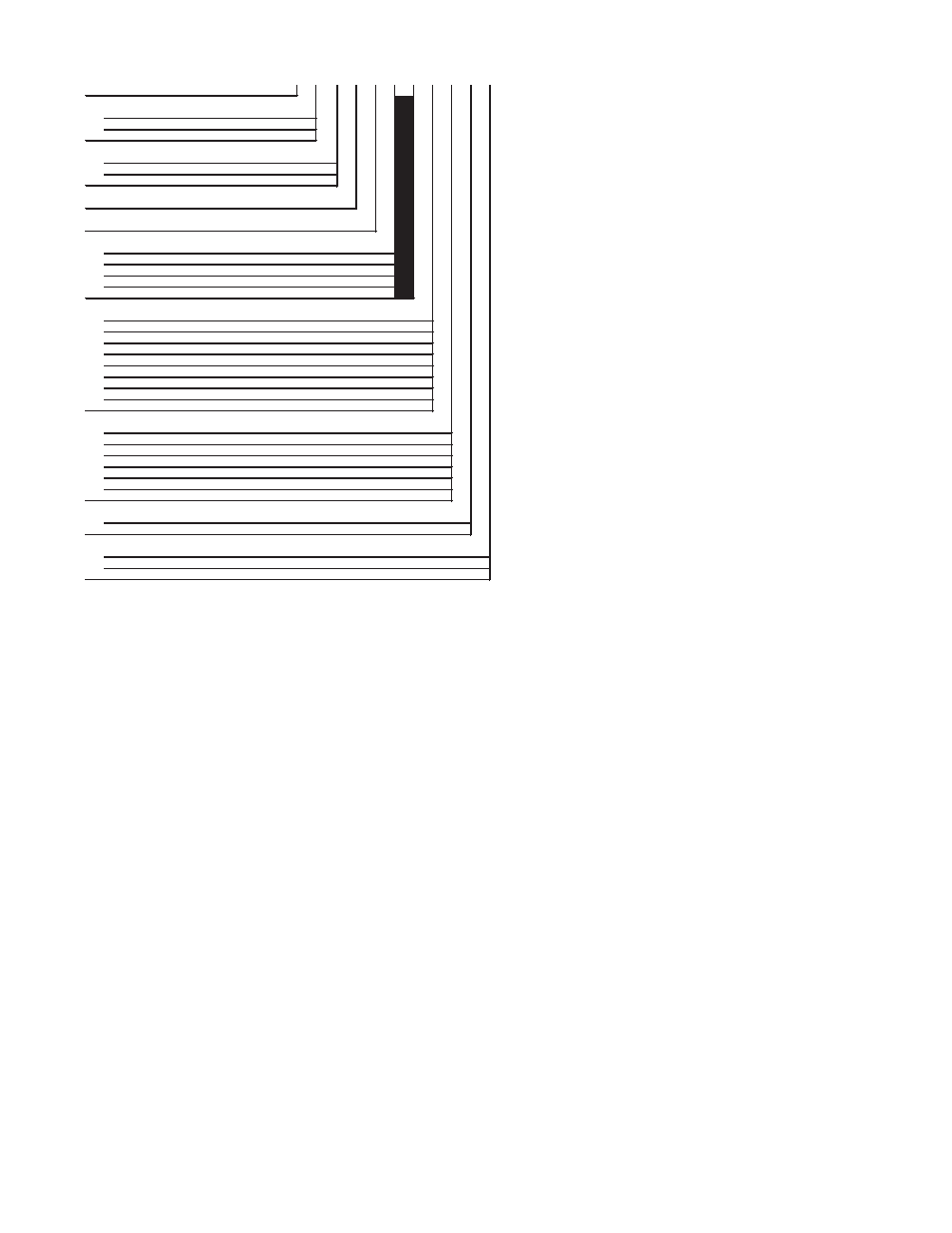

200 Series Insert Style Matrix (sizes 2½" and up)

Example: 2

x

x

x

x

x

-

x

x

x

x

STYLE

Short Insert

20

Hot Tap Insert-Gate Valve

25

Hot Tap Insert-Ball Valve

26

MATERIAL

Brass

BR

Stainless Steel

SS

PVC Sleeve w/Stainless Steel Trim

PVS

Size

Insert Style

00

Electronics Housing

PPS

0

ELECTRONICS

Magnetic

2

FM/CSA Approved

4

Standard

5

IR-Irrigation

6

High Temperature

8

O-RING

Viton®

0

EPDM

1

Kalrez®

2

Food Grade Silicon

3

Neoprene

4

Chemraz®

5

Teflon Encapsulated Viton

6

Teflon Encapsulated Silicone

7

Buna N

8

SHAFT

Zirconia Ceramic

0

Hastalloy® C

1

Tungsten Carbide

2

Titanium

3

Monel®

5

316 Stainless Steel

6

Tantalum

7

IMPELLER

Nylon

1

Tefzel®

2

BEARING

Pennlon®

1

Tefzel

2

Teflon®

3

Models 226SS, IR226SS

This is the same as Model 226BR respectively, except that

the hot tap hardware, ball valve, and sensor sleeve are made

of Series 300 stainless steel.

Model HTT

This is the insertion tool for use with any of the hot tap sen-

sor units. It is used to insert and remove the sensor while

under pressure. Generally, only one HTT tool is needed on

each job site.

MECHANICAL INSTALLATION

General

The accuracy of flow measurement for all flow measuring

devices is highly dependent on proper location of the sensor

in the piping system. Irregular flow velocity profiles caused

by valves, fittings, pipe bends, etc. can lead to inaccurate

overall flow rate indications even though local flow velocity

measurement may be accurate. A sensor located in the pipe

where it can be affected by air bubbles, floating debris, or

sediment may not achieve full accuracy and could be dam-

aged. Badger Meter flow sensors are designed to operate

reliably under adverse conditions, but the following recom-

mendations should be followed to ensure maximum system

accuracy:

1) Choose a location along the pipe where 10 pipe diam-

eters upstream and 5 pipe diameters downstream of the

sensor provide no flow disturbance. Pipe bends, valves,

other fittings, pipe enlargements and reductions should

not be present in this length of pipe.

2) The preferred location around the circumference of a hori-

zontal pipe is on top. If trapped air or debris will interfere,

then the sensor should be located further around the pipe

from the top but not more than 45 degrees from top dead

center. The sensor should never be located at the bottom

of the pipe, as sediment may collect there. Locations off

top dead center cause the impeller friction to increase,

which may affect performance at low flow rates. Any

circumferential location is correct for installation in vertical

pipes.

3) An insertion depth of 1 1/2 inches for pipe sizes 2.5

inches and larger is required for accurate flow rate

calibration. Detailed installation instructions for various

sensor mounting configurations on the following pages

include methods for ensuring correct insertion depth.

4) Alignment of the sensor to ensure that impeller rotation

is parallel to flow is important. Alignment instructions are

also included on the following pages.

INSTALLATION FOR 220BR, 220SS

Installation Procedure

The insertion depth and alignment of the sensor assembly

are critical to the accuracy of the flow measurement. The

flat end of the sensor tube assembly MUST BE INSTALLED

1-1/2 inches from the inside wall of the pipe. In order to allow

for variations in wall thickness, lining, or coatings the depth

adjustment is controlled by the position of the Hex Nuts on

the three (3) threaded studs of the hex mounting adapter.

The hex mounting adapter is provided with a 2 inch male

NPT connection.

There are two methods of mounting these Badger Meter

sensors in a 2.5 inch or larger pipe. One is with a 2 inch

NPT threaded pipe saddle. The other is with a welded-on

fitting such as a Thredolet

®

, also tapped for a 2 inch NPT

connection. In either case, cut a 2 inch hole through a

depressurized pipe and then secure the saddle or weld-on

fitting to the pipe. (For drilling into a pressurized pipe, see

instructions for Series 225 and 226 sensors.) Install the 2

inch NPT adapter provided, using a thread sealant to prevent

leakage. Tighten as necessary. Badger Meter insert style

sensors are calibrated with the sensor inserted 1 1/2 inches

into the pipe flow.

To determine the proper insertion depth, proceed as follows:

1) Apply anti-seize thread lubricant , supplied with the

sensor, to the threaded studs of the mounting adap-

tor.

2) Insert the depth gauge into the mounting adapter and set

it against the inside wall of the pipe as shown. Set the

top of the upper adjusting nut to 3¾ inches as measured.

Lock it in place with the bottom nut on the same stud.

Repeat for the other adj. nuts.

Note:

For Model 220PVS: Set nuts 6.5

inches above inside wall of pipe.