Spicer Single Drive Axles Service Manual: 34DS, 34RS, 38DS, 38RS, DS340, RS340, DS380, RS380, DS400, RS400, DS3 User Manual

Page 90

Differential Carrier Overhaul (Forward and Rear Axle)

87

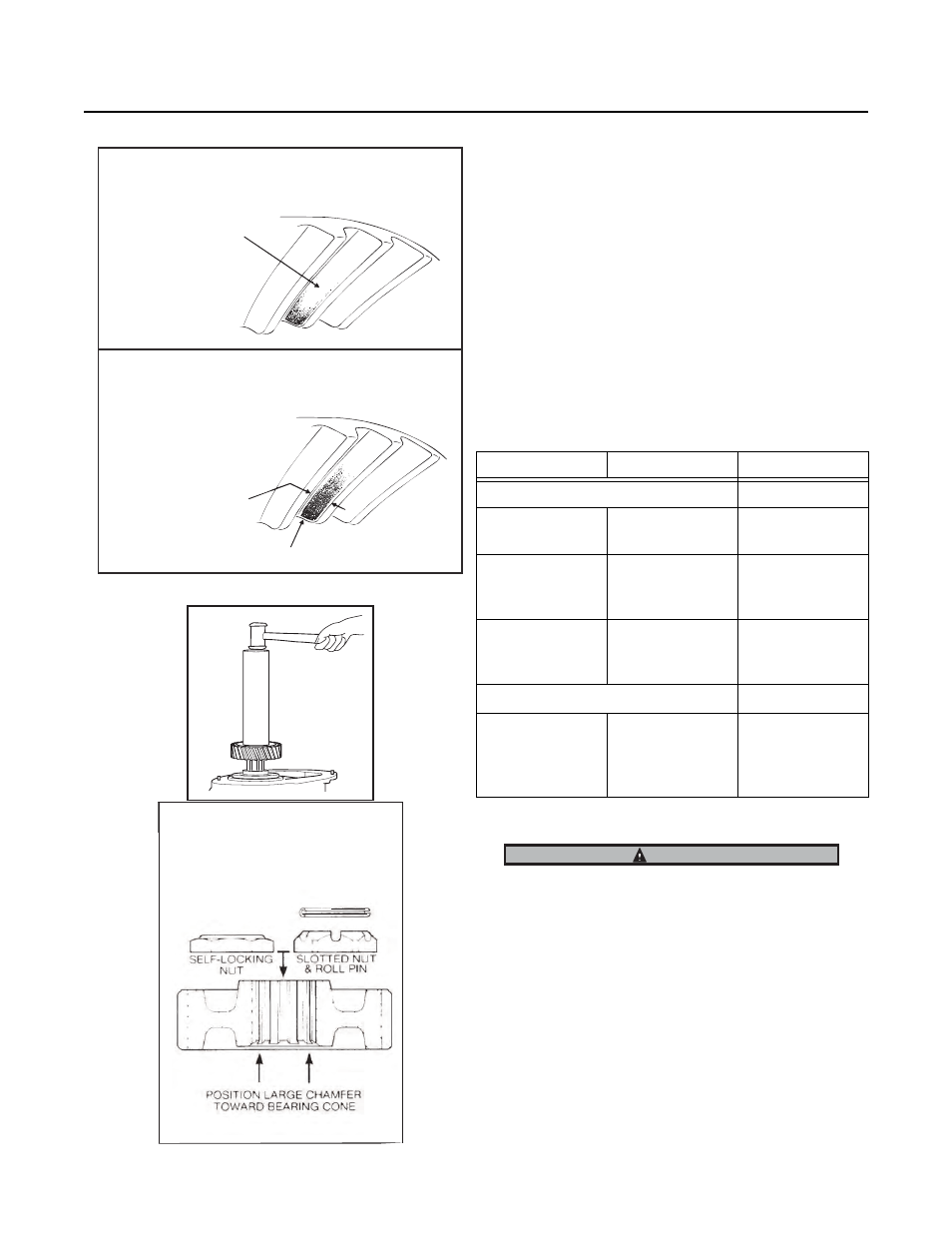

12. Check Ring Gear Tooth Contact. Paint ring gear teeth and

check tooth contact pattern. Correct tooth patterns are illus-

trated below. For checking and adjusting procedures, see

page 22.

13. With ring gear and pinion adjusted correctly, align adjusters

and locks, then tighten differential bearing cap screws to

correct torque (360-440 ft. lbs., 488-596 N.m). Install ad-

juster locks and cotter pins. Lock-wire differential bearing

cap screws.

14. Forward Axle Helical Gear. If dummy yoke was used, remove

nut and yoke. Install helical gear on pinion, positioned as

shown in the illustration. Install nut and tighten to correct

torque (see chart)

*Torque to 840 ft. lbs. (1139 N.m), then continue tighten-

ing nut to align slot with the nearest hole in pinion shank.

Install roll pin.

15. Installing Pinion Helical Gear.

Note: See Torque Chart for Pinion Nut Variations

Torque Chart

Size

Ft. lbs

N.m

Forward Axle Pinion Nut

(D340, 380(P),

400-P) 1 1/2-18

560-700

759-949

(D341, 381(P),

401-P, 402(P),

451-P) 1 5/8-18

780-960

1057-1301

(D341, 402(P)

403(P), 451-P)

M42 x 1.5

840-1020

1140-1383

Slotted Nut and Roll Pin

(D-341, 381(P),

401-P, 402(P),

451-P only ) 1 5/8-

18

840

1139

Pocket may be

extended.

Pattern along

the face width

could be longer.

Correct Pattern Used Gearing

Could vary in length.

Pattern should cover

1/2 tooth or more

(face width).

Pattern should be

evenly centered

between tooth

top land and root.

Pattern should be clear of tooth toe.

Correct Pattern New Gearing

IMPORTANT

Pinion Helical Gear

Mounting Position

NOTE:

See Torque Chart for

Pinion Nut Variations